Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Hey, it's Bill. I'm excited

0:02

to present an episode of another podcast

0:04

that we make here at the Center

0:06

on Global Energy Policy The

0:08

big switch hosted by dr. Melissa

0:11

lot The big switch is

0:13

a narrative show all about rebuilding the energy

0:15

systems that are all around us and Melissa

0:17

is out with a new five-episode

0:20

season about batteries as

0:23

part of the green energy transition batteries

0:25

are finding their way into everything from

0:28

cars and heavy equipment to the electric

0:30

grid but Scaling up

0:32

production to meet the demands of

0:34

a net-zero economy is complicated and

0:36

it's contentious This season

0:38

Melissa digs into the global battery

0:41

supply chain from mining to manufacturing

0:44

And she asks what's getting mined

0:46

traded and consumed on the road

0:49

to decarbonization The

0:51

answer may surprise you We're going

0:53

to play the first episode of that season

0:55

now And if you subscribe to the

0:57

show you can hear the rest

1:00

of her reporting on the rise of the

1:02

battery economy as new Episodes get released over

1:04

the next month. Enjoy. I want

1:07

to tell you the story about a woman

1:10

named Alessandra Carion Alessandra

1:14

is a Renaissance woman and I

1:16

say that because she's not only

1:18

a Michigan Public Service Commissioner But

1:20

also a sustainability expert and I'm

1:23

not kidding. She's the co-owner of

1:25

a verified Neapolitan pizza shop. I

1:28

do in fact Co-own

1:30

a pizza business It's

1:33

a skill that will never go

1:35

away She also has really specific

1:37

skill set in tracking battery supply

1:39

chains So we couldn't help

1:42

but ask her does she use electric ovens

1:44

at the pizzeria at the restaurant because

1:46

we were a Verified

1:48

Neapolitan pizzeria. We used a

1:50

traditional wood fired brick oven

1:53

Alessandra talked to us not only in her

1:55

official capacity as an energy commissioner or as

1:57

a pizza lover But it's someone who it's

2:00

spent nearly a decade tracing the minerals

2:02

and materials that make up power cars,

2:04

and in particular tracing the materials that are

2:07

in our electric car batteries. She

2:09

started her career at environmental consulting, and then

2:11

in 2012 she moved into the

2:13

heart of America's auto industry, which is

2:15

at the start of this major transition.

2:17

Truly, it just felt called to

2:19

move to Detroit, Michigan, especially

2:22

with, you know, sort of the auto

2:25

industry being in a

2:27

pivotal moment back in 2008 onward.

2:29

I could see how much energy

2:32

there was around transforming

2:35

the city in the wake of a lot

2:37

of change. More coverage of

2:39

the financial crisis tonight. The big three

2:41

U.S. automakers are handing over their plans

2:43

for the future to Congress. They're

2:45

trying to convince lawmakers to get them a bailout

2:49

of $25 billion in taxpayer

2:51

money. Companies say one of

2:53

them might collapse without it.

2:57

So at that time, two really important

2:59

stories were playing out. See, a few

3:01

years earlier, America's top automakers were struggling

3:03

in the wake of the financial crisis,

3:06

and they saw that the sales for some

3:08

of their vehicles, particularly those big SUVs that

3:11

tend to giggle gas, well, they'd tanked. Hundreds

3:13

of thousands of production jobs were lost, and

3:15

the government ended up stepping in to

3:17

help them out, pouring nearly $80 billion into

3:21

GM, Chrysler and Ford. General Motors

3:23

and Ford submitted restructuring plans to

3:25

Congress Tuesday. GM promises fewer brands

3:27

and fewer dealers. Ford promises no

3:30

managers will get a 2009 bonus,

3:33

and it will speed up plans for

3:35

electric cars. As a condition

3:37

for the government support, automakers agreed

3:39

to speed up fuel efficiency standards

3:41

to encourage lighter gas-sipping models that

3:44

have been deprioritized. And meanwhile, the

3:46

American Recovery and Reinvestment Act, also

3:48

known as the stimulus bill, created

3:50

federal tax credits for different types

3:52

of electric vehicles. It

3:55

included billions of dollars to support domestic

3:57

battery manufacturing for the first time, and it also included a

3:59

$1 billion bill for electric vehicles. also included this loan

4:01

for a tiny electric car maker

4:03

called Tesla. Alessandra stepped

4:05

into this moment at Ford, where she

4:07

got a job as a sustainability business

4:10

analyst. So that required

4:12

an ability to investigate

4:15

along the supply chain where

4:17

materials came from, how they were being

4:20

processed, who was handling them. And Alessandra's

4:22

work was directly influenced by another very

4:24

important law called the Dodd-Frank Act. This

4:26

act was created in the wake of

4:29

the financial crisis, and it set up

4:31

a whole host of regulatory reforms

4:33

and consumer protection. This

4:37

reform will help foster

4:40

innovation, not hamper. It

4:42

provides certainty to everybody, from

4:44

bankers to farmers to

4:46

business owners to consumers. And

4:49

unless your business model depends on cutting

4:51

corners or bilking your customers, you've

4:54

got nothing to fear from reform. There

4:57

was a provision in the law

5:00

that required publicly traded companies and

5:02

manufacturers to report their sources of

5:04

tin, tungsten, tantalum, and gold. These

5:07

minerals are found in a wide

5:09

range of consumer electronics, jewelry, medical

5:11

equipment, and cars. And they're

5:13

often referred to as conflict minerals, because large

5:16

amounts of them are mined in the Democratic

5:18

Republic of the Congo, where they

5:20

can fund armed conflict and also are

5:22

associated with human rights abuses like child

5:25

labor. Dodd-Frank ignited

5:27

efforts inside large companies like Ford

5:29

to investigate where these materials came

5:31

from, how they were being

5:33

processed, and who was handling them. And

5:40

there were literally thousands of spreadsheets,

5:42

thousands of suppliers to sort through.

5:45

It was really a first

5:47

of its kind moment. And so

5:50

that really sparked and inspired not

5:52

only for Ford, but across many

5:55

industries, companies began to question, okay,

5:58

by law, I need to think about where my tin... and

6:00

then the gold is coming from. But what about

6:02

my lithium? What about my nickel? What about my

6:04

rubber from farms? So

6:07

I was really fortunate to be

6:09

part of the industry and in

6:11

this job at a moment where

6:13

this activity was just scaling and

6:15

expanding in an unprecedented way. And

6:25

that scale only expanded as the

6:28

entire auto industry started embracing electric

6:30

cars thanks to batteries that

6:32

were getting cheaper and better every single

6:34

year. In a brand new plant in

6:37

Michigan, the future of Ford is already

6:39

rolling out. The all-electric version of the

6:41

F-150, the best-selling vehicle

6:43

in America, with 150,000 orders. Now

6:48

Ford tells NBC News exclusively it

6:50

is going all in on electric,

6:52

pledging that within nine years, 40%

6:55

of its fleet will be battery powered. And those

6:58

lithium ion batteries are filled with another

7:00

set of critical minerals, like of course

7:02

lithium, but also cobalt,

7:04

manganese and graphite, which are

7:06

mined, processed, transported, and controlled

7:08

in highly complicated ways. EVs

7:12

represent opportunity to introduce a new

7:14

way of

7:17

planning for virtually new

7:20

blossoming supply chains, value

7:23

chains that are responsible, that take

7:25

into account social and environmental sustainability

7:28

from the onset, if we plan

7:30

it correctly, and the

7:32

ability to introduce more transparency and those

7:34

mineral supply chains that already exist for

7:37

other commodities that we can in turn

7:39

help improve. And this long lead up

7:41

over more than 15 years, the

7:44

stimulus act, the auto bailout,

7:46

Dodd-Frank, combined with batteries

7:48

getting so much cheaper, sparked interest

7:50

in electric vehicles and the battery

7:52

supply chains behind them. And

7:55

they led to this transformative law in 2022 that

7:58

put batteries at the center of the... clean energy

8:00

economy. I'm talking about the Inflation

8:02

Reduction Act. Well, John, there was

8:04

so much attention on solar, wind,

8:06

and hydrogen stocks, but battery companies

8:08

also a key beneficiary of the

8:10

Inflation Reduction Act. By this point,

8:12

Alessandra had left Ford, but she

8:14

was still focused on EV supply

8:17

chains, and the Inflation Reduction Act,

8:19

also called the IRA, added a

8:21

whole new set of stakes. And

8:24

suddenly, government policy wasn't just

8:26

focused on discouraging conflict minerals

8:28

or sprinkling some money into

8:30

R&D. It was about building an

8:32

industrial-scale battery industry from the

8:34

ground up with tens of billions

8:37

of dollars in incentives. And that

8:39

includes tax credits for battery production

8:42

and mineral refining. The second measure

8:44

is linking the EV incentive

8:46

to domestic and allied mineral production.

8:49

And so where the opportunity there becomes

8:51

is not just where are you mining

8:53

these minerals, but if you mine them,

8:56

then where do you send them to

8:58

make cathodes, to make anodes? And

9:00

does the U.S. want to be in the

9:02

business of processing those minerals to make these

9:05

cathodes and anodes that go into the batteries

9:07

that we're assembling? Over time, in

9:09

order for the EV credits to be

9:11

realized, more and more battery components need

9:14

to be mined, refined, or recycled by

9:16

the U.S. or one of our free

9:18

trade allies. John, these are complex and a

9:20

lot of supply chains. This

9:22

question really leads to a

9:25

central topic around sustainability, responsibility,

9:27

and then ultimately economic development

9:29

and ability to thrive in unique

9:31

demand with local supply. This

9:36

is The Big Pitch, a show about

9:38

how to rebuild the energy systems that are all

9:40

around us. I'm Dr. Melissa Lott,

9:42

and I'm the Senior Director of research

9:44

at Columbia University's SIPA Center on Global

9:46

Energy Policy. The

10:00

demands of a natural kind. of me is

10:02

really complicated. And it's consensus.

10:04

This season we're digging into the

10:06

ways the batteries are made and

10:08

were asking what gets mind traded

10:10

and consumes on the road to

10:12

decarbonization. This

10:15

is the first installment in our

10:17

five part series. In this episode,

10:19

the geopolitical race that is transforming

10:21

battery supply chain will open up

10:23

a lithium ion battery. Investigate what's

10:25

inside as can ask the question

10:27

a critical minerals the new oil.

10:33

A global quest to learn how batteries

10:36

are made starts really close to

10:38

home for me right here on the

10:40

campus. A club the University reverse. More

10:42

precisely it starts that the Columbia

10:44

Electrochemical Energy Center. It's just a straight

10:47

away from my office and it's were

10:49

professor. Damn fine art studies how

10:51

energy storage devices work by learning how

10:53

they fail. I do have a gun

10:56

and here we're going to like

10:58

slow as a battery. Will hopefully

11:00

won't blow up, but we're gonna cut it

11:02

open in a way that's really not meant

11:04

to be cut open because were trained professionals

11:07

are my student for it's actually getting his

11:09

Phd in setting boundaries of hard various ways

11:11

or he spent most of time flowing batteries

11:14

often so taser a safety for were giving

11:16

the day off. Okay,

11:18

that picture this for in this

11:20

lab and I'm standing next to

11:23

Dan and his Phd students. that

11:25

Schumacher and around Us cities white

11:27

cinder block walls, their lives, a

11:29

copper pipes and covenants filled with

11:31

chemicals, the talking cylinders, speakers, lox

11:33

just everywhere. And it's in this

11:36

lab that researchers are performing all

11:38

these crazy kinds of experiments. stress

11:40

test the batteries that go into

11:42

our cars and the electric fence

11:44

sitters figure out how when and

11:47

why they sail. Who

11:49

has invited? He decides he wouldn't see batteries.

11:51

Apart for your work on I

11:53

guess I recall chaotic neutral where

11:56

I live on. me

12:00

It's just, it's exciting and it's also impactful,

12:02

right? A lot of people work on battery

12:04

performance and making batteries better, make them better,

12:06

more energy, but that means a lot more

12:08

bad things can happen, right? Especially in the

12:10

city, you have a lot of battery

12:13

fires and a lot of people get hurt. So

12:15

the way that we can figure out how to not make

12:17

that happen is to study what's

12:19

happening when that happens. So that

12:21

just, I found my little niche

12:23

of battery explosions. We

12:25

spend a lot of time trying to make batteries

12:27

better and spread the said, improve the energy density,

12:29

improve the power density. Classically

12:32

anything that has high energy density, something

12:34

that stores a lot of energy in

12:37

a small amount of space, high power density can

12:39

give that energy very quickly. We

12:41

don't want batteries to be bombed. So the question is,

12:43

how do we have a battery that gets us a

12:45

300 mile range that can be charged

12:48

in five minutes that has zero

12:50

danger of exploding, right? It's probably

12:53

impossible completely, but

12:55

understanding how and why they

12:57

explode is something really

13:00

important and tragically understudied.

13:03

Okay, let's go blow

13:05

something up. Open something up. Open

13:08

something up. Don't burst my

13:10

bubble yet. We're going to blow it up. No, let's go. Let's

13:13

go open something. I can't wait to see what's inside of this thing. Okay.

13:16

If you throw on our safety glasses and Dan

13:18

and Brett take me over to our protective shield

13:20

and behind that shield, there's this

13:22

cylinder shaped battery. It looks

13:25

kind of like a double A battery, but it's slightly

13:27

larger. It's a cell called an 18650 and

13:29

that's battery speak for 18 millimeters

13:32

in diameter and 65 millimeters

13:35

in height. And this type

13:37

of lithium ion cell was rumored to be

13:39

used in the original Tesla Model S. The

13:42

idea that the cell that Brett

13:44

is taking apart for you today

13:47

would be the commodity cell

13:49

when I was Brett's age 20

13:52

years ago was seemed impossible,

13:55

but through just brutally efficient

13:59

engineering. It turned out

14:01

to be the linchpin for enabling

14:03

low-cost storage. So

14:06

Brad puts on these black protective gloves and

14:08

he starts to unravel the battery. And as

14:10

he's doing it, he's unveiling these long

14:12

strips of material that have been layered together

14:15

in a tight coil. And so if I

14:17

turn this on its head, or I guess on

14:19

its belly, what it'll look like is you see

14:21

this white here, and it's almost like a tree,

14:23

it's like concentric ring. So this is what we

14:26

call a jelly roll. What we

14:28

have actually is a really

14:30

long foil of electrodes. So

14:33

I can roll this all the way out,

14:35

and it's actually two electrodes that are just

14:37

super, super, super long. It's just

14:39

like a fruit roll-up. Yeah, exactly. So

14:43

I can roll this all the way out. And when

14:46

we rolled it all the way out, we

14:48

saw four parts made up of different materials,

14:51

which are sourced from all over the world. You

14:54

have your cathode and your anode. Those are

14:56

what you're actually going to be storing your

14:58

energy in. So your anode is your minus

15:00

sign if you're thinking of a AA battery,

15:02

and your cathode is your positive sign. In

15:05

these specific cells, we have

15:07

what's called nickel cobalt aluminum.

15:10

Our active materials on our cobalt side,

15:13

our positive side, that's going to help

15:15

store our lithium. On our opposite side,

15:17

our anode, our negative side, is going

15:19

to be graphite. That's usually what is

15:22

used in most conventional lithium-ion batteries

15:24

now. In between those two

15:26

is what we call a separator. Very

15:28

simple. It keeps the two apart, right? Whenever

15:31

we think of battery safety, the

15:33

one thing we don't want to do is

15:35

touch those two together. It's like licking

15:37

a battery, right? You get a little shock. So that's

15:39

the same thing. A separator is supposed to keep it

15:41

safe on the inside. That'll

15:44

look like a white polymer. It's usually

15:46

polypropylene, so a very common polymer. And

15:49

the way we need to make sure that

15:51

these lithiums can travel between these two electrodes,

15:54

so we use electrolyte. It's not

15:56

Gatorade. It is some sort of lithium

15:58

salt dissolved. be so cool

16:00

if it was. That's so awesome. Yeah, it'd be great.

16:02

It wouldn't be flammable too, which is awesome. But

16:05

usually what it is, it's some sort

16:07

of lithium containing salt dissolved in solvents,

16:10

like carbonate. It's like this liquid,

16:12

clear liquid that dissolves the salt in.

16:15

And that allows for the lithium ions actually to

16:17

transport between them. All right,

16:20

so we got an anode, a cathode, we got some

16:22

polymer, and then we got a lot of lithium

16:24

moving stuff around. It's basically what it's like. Yeah,

16:26

yeah. So like when we're charging a battery, what

16:28

we're actually doing is we're moving lithium ions from

16:30

one side of the battery to the other. So

16:32

when the lithium moves over at the positive ion,

16:35

we get an electron, that's electricity. So that

16:37

will go and power our cars or our

16:39

light bulbs or something like that. So the

16:41

act of moving that lithium ion is actually

16:43

pushing an electron through a circuit that we

16:45

can actually harness for energy. I've

16:51

never taken apart a battery before. So

16:53

watching Brett uncoil all the materials was

16:55

really cool to see. I'll admit I

16:57

was tiny bit disappointed that I didn't

17:00

see any small explosions, but that's a

17:02

really good thing. Because 20 years ago,

17:04

explosions were much more common in lithium

17:06

ion batteries. And the cell

17:09

that we dissected, which was perfected by Tesla, was

17:11

a big deal in terms of design. When

17:13

I started grad school, it was thought that this cell

17:16

had to be much larger and be much fancier. And

17:18

they kept on blowing up. In fact, they blew up

17:20

so much that I wasn't allowed to work on them

17:23

at Lawrence Berkeley Lab. And my project had to

17:25

change. Six years later, after

17:27

all of these batteries catching fire, the

17:29

initial team at Tesla said, let's just

17:31

use cells that we don't know don't

17:34

explode, which are cells that are in

17:36

laptops. So the immediate predecessor to the

17:38

cell that Brett took apart was used

17:40

in a laptop that looked exactly the

17:43

same. The pack

17:45

was very expensive. The initial Tesla Roadster

17:48

cost $150,000 and went

17:50

maybe 150, 180

17:52

miles, right? So certainly not the mass

17:54

market vehicle, but it

17:56

set in motion the understanding

17:59

that all All of this stuff can be made

18:01

much cheaper. And so

18:03

that little cell, as premium

18:05

and or insignificant as it might

18:07

be, a laptop battery designed

18:10

for systems in

18:13

1996 turns out to be

18:15

the crucial storage element of the energy

18:17

transition. When

18:23

I was looking at this battery cell and talking to

18:25

Dan and Brett, I was really hit by

18:27

the scale of what I was looking at.

18:30

There were about three feet of materials wrapped

18:32

up inside a cell in the lab. A

18:35

Tesla battery pack hosts like 10,000 of

18:37

those cells just in a single car. In

18:40

fact, EVs today can have hundreds

18:42

and even thousands of lithium-ion cells.

18:44

And that means that the typical

18:46

electric car on the road can

18:48

have between three and four miles

18:50

of really thin material, material that

18:52

is mined, processed and assembled all over

18:55

the globe. So after our

18:57

lab visit, I sat down with Dan in his

18:59

office to run through how it all worked from

19:01

beginning to end. So

19:09

if we break down how you make

19:11

a battery, what are the big steps

19:13

to actually taking a bunch of raw

19:15

stuff and turning it into a battery?

19:18

Well, first you have to get the raw stuff. You have

19:20

to dig it out of the ground. You have to find

19:22

the right veins. Almost everything that's in a battery by mass

19:25

that is a significant amount of

19:27

money is a metallic or metal-like element.

19:30

The most commonly used minerals

19:32

are lithium, cobalt, graphite, manganese,

19:34

nickel and copper. And

19:36

it's important that we know where these minerals come from.

19:39

So 80% of lithium comes from

19:42

Australia, China and Chile, where

19:44

70% of cobalt comes from the Democratic

19:46

Republic of Congo. 60%

19:49

of manganese comes from South Africa, China

19:51

and Australia. And China

19:53

sources 80% of the world's

19:55

graphite. Indonesia is the

19:58

world's dominant nickel producer. in

20:00

Peru are the world's top copper producers. We get

20:02

the minerals like we get any other metals. We

20:04

mine them out of the ground and then we

20:06

have to take extra care in purifying them. And

20:09

as batteries have found their

20:11

way into bigger applications, cars and

20:13

now the grid, the cost of

20:15

that purification has dropped substantially. And

20:18

this should have been predictable to be because I saw

20:20

it happen 10 years earlier with silicon but I said,

20:22

oh, this can happen with batteries. And

20:24

it turns out that luckily it could. And so it's

20:26

a great thing. And just like

20:28

it does when it comes to silicon

20:30

for semiconductors and solar cells, China dominates

20:32

here as well. In fact,

20:34

China controls 85% of all

20:38

critical minerals processing and refining.

20:40

So after we mine and purify, we

20:43

get to synthesizing the material as a

20:45

part of the battery production process, which

20:47

is incredibly sophisticated and precise. The

20:49

synthesis makes sure the elements are exactly

20:51

in the right order. It's not just

20:53

good enough to have nickel, cobalt and

20:56

manganese in some ratio mixed

20:58

together, hope it works out. You want

21:00

the nickel in one layer and then a

21:02

layer of oxygen and then a layer of

21:04

manganese and then a layer of cobalt. And

21:07

there's not the same amount of nickel, manganese

21:09

and cobalt in the electrode. And

21:11

so nickel has to be every

21:13

other layer and the manganese and the cobalt

21:16

will be interspersed every fourth

21:18

layer. And then it could be

21:20

every eighth layer and so forth. This

21:22

level of control is frankly amazing.

21:25

This whole process makes me think of Goldilocks

21:27

and three bears like getting it just just

21:29

right, except for we're talking about getting it

21:31

right at the atomic level. At

21:34

the atomic level. And ideally,

21:37

I would place every atom. But

21:40

again, this has to be really cheap. And I have to make millions

21:43

of tons of it a year. So with a

21:45

computer chip, I don't need millions of tons of

21:47

computer chips. They can be these

21:49

precious little gems relative to a battery. So I

21:51

need the kind of control. Ideally, I want the

21:54

kind of control I have in a computer chip

21:56

but made it the scale of dog food. In

21:59

case you aren't keeping... So far

22:01

in this episode, we've referred to jelly

22:03

rolls, fruit roll-ups, Gatorade, the three

22:05

bears porridge and Goldilocks, and now

22:07

dog food. And we've got one

22:09

more for you. Now that

22:11

we've mined, purified, and synthesized the material

22:13

that we need, we have to layer

22:15

it to make something that looks like

22:17

baklava. And yes, I'm talking about

22:20

that amazing and slightly sticky dessert that many

22:22

of us have enjoyed. Now imagine

22:24

you go to your favorite bakery and you

22:26

say you have to make kilometers of baklava

22:29

that with the separator spacing between

22:31

the anode and the cathode is about 15 microns.

22:35

And so not only are these layers precise

22:37

within themselves, but they have to be precisely

22:40

aligned over these distances. You've got

22:42

mining, then you've got purifying, and then

22:44

you've got a lot of different steps

22:46

that go into a bucket that could

22:49

be called manufacturing. And so

22:51

at this stage, we have a cell. What

22:53

happens next? This is the part I

22:55

love because now we have the Legos. The

22:58

cell is really hard to make. A

23:00

lot goes into it. Manufacturing

23:03

know-how over the Industrial Revolution

23:05

from the Industrial Revolution to

23:08

2023 is about doing one thing and

23:11

doing one thing over and over again and then having

23:13

that be a building block. At

23:15

this point in the process, the difficult chemistry is

23:17

behind us. And the assembly

23:19

process is all about stringing the cells

23:22

together into packs, up to 10,000 cells

23:25

in a single pack. It's still

23:27

pretty difficult, but you no longer need

23:29

specialized clean rooms. You can do it

23:31

virtually anywhere. You can ship these cells.

23:33

They're formed. They can be created.

23:35

And so while we

23:37

want to produce more cells in the US,

23:39

the fact that these cells can be made

23:41

with these precisions in Korea,

23:43

in China, in Japan, it's where most of

23:46

the manufacturing systems, there's a good amount happening

23:48

in the US, there has to be a

23:50

lot more. But once these cells

23:52

are made, you can do what we

23:54

call pack out, making the modules, making

23:56

the packs wherever. It's really incredible. So

24:00

that is a snapshot of how lithium ion batteries

24:03

are made. The process is

24:05

really sophisticated and every single step

24:07

is expanding quickly as the world's

24:10

appetite for batteries increases. That

24:12

means that we're going to need more of everything

24:15

that goes into them. The needs by 2040 are

24:17

scary, but by 2030 they might be even scarier. Because

24:21

mining and processing takes a lot of time. So

24:24

for lithium that's about seven to eight times more

24:26

by 2030. Nickel

24:28

and cobalt need to double and copper about

24:30

50% more, which are

24:32

a gigantic amount. Tom

24:34

Morinhout is a research scholar here at

24:37

the Center on Global Energy Policy. And

24:39

when Tom thinks about decarbonization, he looks

24:41

at it to the lenses of trade,

24:43

investment and industrial policy. According

24:46

to McKenzie, the global supply chain for batteries

24:48

in 2022 was around $85 billion. And

24:53

by 2030 it's expected to be worth $400 billion,

24:56

thanks largely to demand for things

24:58

like electric cars and also storage

25:00

on the electric grid. Whoever

25:03

controls that supply chain has enormous

25:05

power. So who currently

25:07

wields it? I think the obvious

25:10

candidate is China, right? So China is

25:12

definitely building geopolitical leverage with their control

25:14

over overdose supply chains. I think other

25:16

countries are currently reacting

25:19

to it. China leads

25:21

the E.B. race in part because

25:23

it controls the supply chain of raw

25:25

materials for batteries. 28%

25:29

of the world's lithium, 41% of

25:31

cobalt, threw stakes and mines on

25:33

five continents. The biggest concern

25:35

is that they would use their

25:38

supply chain dominance to basically

25:40

gain geopolitical leverage. That's

25:42

the biggest challenge. And I think that that

25:44

risk is very real. Why

25:56

should we care about China controlling so much

25:58

of the world's battery supply chains? Why

26:00

does this matter? So there are two sides

26:02

to that also. The first one is that

26:05

we should care because the numbers are

26:07

just insane. They're staggering, right? On

26:10

the refining side, China controls 80% of

26:13

manganese refining, more than 70% of cobalt and

26:16

nickel refining, more than 60% of

26:18

lithium refining. And then you

26:20

get to the most valuable components, the cathodes, the

26:22

anodes, right? China controls more than 75% of cathode

26:24

production, more than 90% of anode production. And

26:29

then eventually with respect to battery cells, they control more

26:31

than 75%. Now, those are a lot

26:33

of percentages, but I basically didn't say anything below 60%.

26:37

It wouldn't matter if it was Australia

26:39

or Canada or even Europe.

26:42

Those numbers are scary because you

26:44

are at risk of supply chain

26:46

restrictions due to things like extreme

26:48

weather events, local conflicts, right? That's

26:51

the first part. The second part is, of course,

26:53

we should care because there are concerns that China

26:55

indeed will use that leverage

26:57

for geopolitical power. China

27:00

is perceived as almost a kind of

27:02

boogeyman in international trade, and there

27:04

are clear reasons why. It's a

27:06

state-directed economy that often uses businesses

27:08

and export restrictions to retain its

27:10

dominance in a wide variety of

27:13

technology sectors. And batteries are

27:15

no different. So just as an example, China

27:17

refined 90% of the world's graphite. And

27:21

at the end of 2023, China

27:23

restricted graphite exports in an effort

27:25

to protect its own supply. And

27:28

this restriction sent battery makers scrambling. But

27:31

they can also be wrongfully bashed. So

27:33

early on, China saw the strategic importance

27:36

of technologies like solar and batteries, and

27:38

they acted on it, building some of the most

27:41

competitive technologies in the world. China

27:43

had a vision for a battery-powered future,

27:45

and they built a very successful industrial

27:48

policy around it. That is

27:50

partially evidenced by control over supply

27:52

chains, but also by technology.

27:54

If you look today at the best

27:56

type of batteries, the best cathodes in

27:58

the world, there are That is Chinese

28:01

technology and that has developed over a

28:03

number of years, one,

28:06

two decades at least, where

28:08

they had a clear strategy while

28:10

other automakers and countries were, yeah,

28:13

sorry for the pun, but asleep behind the wheel.

28:16

And while China dominates a lot

28:18

of the world's battery supply chains,

28:20

many other countries like China are

28:22

establishing their own trade restrictions. One

28:25

example is the Inflation Reduction Act

28:27

here in the US. This is

28:30

America's green industrial policy and it

28:32

gives some real advantages to US

28:34

companies. I'm talking about domestic incentives

28:36

that angered even America's close European

28:38

allies. This green industrial

28:40

race has added to an already tense

28:42

trade relationship between the West and China

28:45

and batteries are one of the reasons

28:47

why. The last few years have

28:49

been very, very, very bad. And

28:52

there's two drivers to that. First,

28:55

you have battery prices that are plummeting. And that's

28:57

a great thing for the energy transition, right? But

28:59

all of a sudden, all automakers

29:01

have to electrify. In the United States, in

29:03

Europe, if you don't do it now, you

29:05

fall behind and you have no future in

29:08

the electric vehicle industry, which

29:10

means that all of a sudden, all

29:12

of the stuff that China was producing, we now

29:14

really need a lot of it, right? So

29:18

that came at the same time as COVID. So

29:20

you have a lot of stimulus packages, right? So

29:22

you have a lot of subsidies that are now

29:24

trying to encourage, hey, let's do more of that

29:26

stuff. EVs, battery cells, catatas,

29:28

anodes, and so forth at

29:31

home, right? And

29:33

there, I think those two

29:35

have gotten us to a level where

29:37

there is a lot more sensitivity. And

29:40

where we have seen the US

29:42

stand up and say, if you

29:45

want to play a game of export restrictions,

29:47

which you have been doing in the last

29:49

basically decade, decade and a half, we

29:52

can play ball, right? And

29:54

so you have seen the CHIPs Act, where

29:56

the United States actually prohibits recipients

29:59

of subsidies. to expand

30:01

business in China, that is a

30:03

very aggressive protectionist

30:06

measure, in theory. And

30:09

I think we've seen the same thing coming

30:11

from China, where they say, look, now if

30:13

you export gallium and germanium, which are two

30:15

very important elements for chips, you need to

30:18

have a license from the government, which of course

30:20

gives them the control over exports as well. And

30:23

so there we have gotten now to the situation

30:25

of pure competition. I think it's fair

30:27

to state that China is not unique in

30:29

using trade as a geopolitical tool. Like, lots

30:32

of countries do that. Do you have a

30:34

couple of examples that stand out to you

30:36

actually of that point of countries using trade

30:39

restrictions within, I mean,

30:41

specifically the battery supply chains, as some

30:43

type of geopolitical tool? Absolutely.

30:45

As a geopolitical tool, and I would

30:47

say as a local industrialization tool, right,

30:49

to jump on industrialization.

30:52

So geopolitics is one thing. And for

30:54

me, when you talk about geopolitics, a

30:56

lot of it is also about achieving

30:58

foreign policy goals, right, or having a

31:00

specific type of influence in

31:03

that sector. I would say with respect to

31:05

industrialization, a lot of countries, what we see

31:07

today, are trying to use export restrictions to

31:11

also add more valuable

31:13

sectors to their economy. So if

31:15

you are a nickel producer, what

31:17

happened before is that you just

31:19

export it. And the more value

31:21

added segments like processing, cathode manufacturing,

31:24

and so forth, were happening elsewhere,

31:26

China specifically. We now

31:28

see countries doing that differently, right? So

31:30

Indonesia, for example, implemented a nickel

31:32

export ban over several years to

31:36

force investment into Indonesia's

31:38

processing capacity. And that

31:40

worked very well. Other countries are looking at that

31:42

and are saying, hey, we might want to do the same

31:44

thing. We have a lot

31:46

of countries that are going to be able

31:48

to go to Africa, to Africa countries, for

31:52

example, Zambia and DRC, with respect to Cobalt. Chile

31:56

has recently nationalized its lithium industry.

32:00

the Chilean state owned enterprise. So

32:02

we're seeing a lot of countries doing that. Whether

32:04

that will work, that's a big question.

32:07

Can the energy transition actually happen

32:10

on the timeframes and at the scale

32:12

we're talking about without cooperation with today's

32:15

major players in battery supply chains, including

32:17

China? No, zero chance,

32:19

not at all, not in a million years. So

32:26

it sounds like the future of battery supply chains

32:29

is global, is that fair? Absolutely,

32:31

yeah. The future of battery

32:34

supply chains is global for

32:36

sure. We'll see some

32:38

more investment happening, right? Very similar to

32:40

refineries, but the amount of demand we're

32:42

going to have for batteries is off

32:44

the charts and we'll only be able

32:46

to supply it with integrated global supply

32:48

chains. We

32:53

need to electrify a lot of the global economy

32:55

if we want to hit net zero emissions by

32:58

2050. The International

33:00

Energy Agency says that growth in annual

33:02

electricity demand will need to double through

33:04

the middle of the century. And that's

33:06

going to require a lot of batteries

33:09

to electrify transport and more

33:11

batteries in our buildings and even more batteries

33:13

across the entire grid to balance out vast

33:15

amounts of wind and solar. And

33:18

so this brings us to a really central

33:20

question about the battery economy. Are

33:22

we just going to swap out dependence on

33:24

petroleum for dependence on critical minerals from China?

33:27

Elon Musk has called lithium the new oil.

33:31

Is he right? We're

33:37

going to need a huge increase in mining

33:39

and minerals, but we should put it in

33:41

proper context in the scale of global

33:44

oil gas trade. Jason

33:47

Bordoff is the founding director of Columbia

33:49

University's SIPA Center on Global Energy Policy

33:51

where I work. But I've known Jason

33:53

since 2009 when we were

33:55

working together in the White House. And I turn

33:57

to him whenever I have questions about the geopolitics

33:59

of the world. of the energy transition. Jason

34:02

was special assistant to President Barack Obama and

34:04

senior director for energy and climate change at

34:07

the National Security Council. So he knows a

34:09

thing or two about the oil and gas

34:11

transition. Jason Blum, CEO, National Security Council, United Nations Oil

34:13

and gas are incredibly important strategic and economic commodities.

34:15

We've seen that time and again over the last

34:17

hundred, hundred and fifty years. I

34:19

spoke to Jason almost to the day

34:21

of the 50th anniversary of the Arab

34:23

oil embargo. It was striking

34:26

that we were discussing China's dominance in

34:28

the clean energy sector right at that

34:30

moment, of that anniversary. I wanted

34:32

him to explain the differences and

34:34

the similarities between the battery economy

34:36

and the fossil fuel economy. When

34:39

we think about the massive quantities of materials

34:41

and minerals that we're going to need to

34:43

get to net zero emissions, how

34:46

do they compare to oil and gas? The

34:48

global oil and gas trade is massive.

34:51

The IAs, one of the

34:53

IAs scenarios that gets you

34:55

sort of close to 1.5 degrees, if not

34:57

all the way, has critical mineral

34:59

revenue growing from 41 billion in 2019 to 263 billion

35:01

by 2040. Again, that's not all the way to

35:04

1.5, maybe

35:09

1.7 or 8. By

35:11

comparison, annual revenue from oil and gas this

35:13

year is over $7 trillion. And a lot

35:17

of this is just volume. The

35:20

volume of critical minerals needed to power

35:22

the global economy in the clean energy world are not

35:24

as big as they are for oil and gas. Even

35:27

on a net zero pathway, critical

35:30

minerals demand does not top 30 million

35:33

metric tons in 2040, according to

35:35

the IEA. And by comparison, to

35:38

30 million metric tons. Oil

35:41

production last year was 4.4 billion metric

35:44

tons. Coal was 7.5 billion tons. So

35:50

the global oil and gas industry is

35:52

enormous. And yes, we're

35:54

going to need more mining. We're going to need more

35:56

global trade in these minerals, but it really doesn't compare

35:58

to how massive. global oil and

36:01

gas businesses. And when we think about

36:03

the geopolitics of all this, how

36:05

are minerals the same and different from

36:07

oil? I think there's a

36:09

lot of sometimes facile comparisons between oil security

36:12

and mineral security. And you hear some politicians

36:14

say things like, I don't want to go

36:16

from dependence on the Middle East for oil

36:18

to dependence on China for minerals. And

36:21

there is something to that. We want to

36:23

be concerned about the dominance of any one

36:25

country, particularly one that is

36:27

not always playing by free and fair rules

36:29

of global trade or that the US has

36:32

significant and Europe has significant tensions

36:34

with like China. But

36:36

there are a lot of really important differences

36:38

too. These are not the same from

36:41

the standpoint of scale or from the

36:43

standpoint of the energy security risks. Oil

36:46

is the

36:48

daily flow of energy. If we were

36:50

to see any cut off in the

36:53

daily flow of oil, your ability to

36:55

heat your homes in some parts of

36:57

the country, to power our transportation sector

36:59

would grind to a halt or prices

37:02

would go through the roof. If

37:04

you saw a disruption in critical mineral

37:07

supplies, that wouldn't affect your ability to

37:09

get energy from say electricity or

37:12

to power your home. It

37:15

would cause shortages, delays,

37:18

cost increases in the supply chains

37:20

for minerals. So critical minerals are

37:23

an input to a manufactured good

37:25

that can produce energy or store

37:27

energy. It is not energy. We

37:30

don't burn critical minerals for energy. And

37:33

so if we had a disruption in some

37:35

types of critical minerals, you might see

37:38

delays and much higher costs

37:40

for batteries. You might have to wait six months or

37:42

12 months to be able to buy a new electric

37:44

vehicle. You might see delays in solar panels. It wouldn't

37:46

affect your ability to charge your electric car today or

37:49

get electricity from your solar

37:51

panel today. So the risks

37:53

to the macro economy are

37:55

different than they are for oil. in

38:00

battery supply chains. Although the

38:02

fossil fuel economy actually dwarfs the

38:04

battery economy in volume, there are

38:06

ways in which critical minerals create

38:08

even more concerns about energy security

38:10

than oil. And the

38:13

biggest risk is concentration.

38:15

So the top producers of oil in the

38:17

world, the US, Saudi Arabia, and Russia, each

38:20

produce roughly 10% of global

38:23

crude oil supply. The

38:25

top producer of lithium, of

38:28

cobalt, of rare earths, each

38:30

of those, the top producers, each of

38:32

those produces more than half, and in some cases up to

38:34

70% of global supply. So

38:37

there's much more concentration today in who

38:40

produces these so-called critical minerals.

38:43

That concentration brings a whole bunch

38:45

of concerns about supply shocks due

38:47

to things like expert restrictions, extreme

38:50

weather, or even another pandemic. So

38:53

when I spoke to Jason, he said

38:55

that all things considered, he'd rather have

38:57

the critical mineral security problem to solve

38:59

than the oil security problem to solve.

39:02

Oil is partly about technology, but

39:04

very much about geologic abundance. Some countries have

39:06

oil on the ground, and some don't. With

39:09

critical mineral dominance that China has, most of

39:11

that is about refining and processing. Those are

39:13

manufacturing plants, and you can build those in

39:15

lots and lots of places. And

39:18

so if we're concerned about the dominance of any

39:20

one country in the supply chain for geopolitical reasons,

39:22

or just because you want to diversify, you might

39:24

see a hurricane or a typhoon hit a certain

39:26

country. You see that with Apple now, which is

39:28

trying to increasingly build iPhones in

39:31

India, not just China. It's just good business

39:33

practice, especially we've been reminded after

39:35

the pandemic, to diversify supply chains.

39:38

We can build those refining and processing plants

39:40

in many places. I know that

39:42

you were a part of the Aspen Institute report that

39:44

was called a critical minerals policy for the United States.

39:47

In that report, you and others outlined

39:49

a bunch of recommendations for U.S. policy

39:51

around critical minerals. Could you

39:53

step us through just the most important

39:55

steps that governments can take, and where,

39:59

if anywhere, is the best way to do it? Is there some low-hanging fruit that

40:01

we could go ahead and move on soon? And what

40:03

steps are actually going to be a lot more

40:05

difficult? There's a lot that the

40:07

US government should be doing to expand

40:10

critical mineral supplies and increase security

40:12

of supply. First, we

40:14

will need more mining. And

40:17

if you're going to diversify supply chains away from

40:19

countries like China, we're going to need permitting

40:23

reform to make it easier

40:25

to do mining projects in

40:28

the United States. You need to

40:30

do that incredibly carefully. We spend a lot of

40:32

time in the report talking about the risks to

40:36

Native American communities. Many of these

40:38

resources are located within a short

40:40

distance of federal lands, public lands,

40:42

sensitive areas, Native American communities. And

40:45

so you need to be really careful about how you do that. But we

40:47

have to make it. Right now, it takes according to

40:49

the IEA an average of 16 years to bring

40:51

a new mining project to development. We have

40:53

to shorten those timeframes. And

40:56

we can also put in place measures

40:58

on the demand side to reduce how

41:00

much minerals we need through technology and

41:03

through other measures that might actually allow us to

41:05

get to the same place with fewer of these

41:07

critical mineral inputs. Second,

41:10

we spent a lot of time

41:12

in the report and engaging with

41:15

tribal communities and indigenous communities to

41:17

make sure that any energy transition

41:20

and any dramatic increase in critical

41:22

minerals mining, refining and

41:24

processing is done in a

41:26

way that is just and equitable. And the mining

41:28

industry does not always have a great track record

41:30

in this regard. So in particular,

41:33

we talked about the need to clarify

41:35

and enforce indigenous sovereignty through

41:37

the so-called concept of

41:39

free prior and informed consent

41:41

with consent directly from impacted

41:43

tribal communities. And that needs

41:45

to be a prerequisite for critical

41:48

mineral development. And

41:50

then third, we talked about the importance of

41:52

trade, that we can't do this alone. We

41:55

can't do this on a path of isolationism

41:57

and protectionism. We need a lot of partners.

42:01

First, there's almost no scenario where China does

42:03

not remain a very important part of these

42:05

supply chains, albeit maybe less

42:07

dominant than today. And you need

42:09

to think about the tools to de-risk

42:11

that, to reduce the risks of that

42:14

dependence, and put in

42:16

place tools to deal with shocks, geopolitical

42:18

or otherwise. And then we

42:20

need to diversify supplies. In order to do

42:22

that, we need to build

42:25

stronger partnerships with lots

42:27

and lots of other countries in Africa,

42:29

Latin America, and Southeast Asia. That's

42:32

really important because right now, protectionism

42:35

is on the rise, on

42:37

both sides of the aisle, and in many parts of

42:39

the world. And we're

42:41

going to need more free trade agreements and

42:43

more free trade partnerships, not fewer, if we

42:45

want to have a clean energy transition and

42:47

diversify our clean energy supply chains. And

42:50

if every country says we need to own the

42:52

entire supply chain because we want all of those

42:54

economic benefits, it's going to make the clean energy

42:56

transition so much harder. The

43:04

battery economy is here, and it

43:07

is shaping so many things. I'm

43:09

talking about global trade, geopolitical relationships,

43:11

domestic industrial policies, climate targets. But

43:14

battery supply chains also matter to every single

43:17

one of us. There are

43:19

millions of jobs at stake, and there

43:21

are environmental and human costs to mining.

43:23

And the availability of batteries has

43:25

direct impacts on the health of

43:28

the grid, and the affordability of

43:30

mobility and electricity. And

43:32

people like Alessandra Carreon, who now serves

43:34

as a public service regulator in Michigan,

43:37

are grappling with the real world consequences

43:39

of how battery supply chains are

43:41

structured. I can't

43:44

imagine how we

43:46

can justify ongoing investments

43:49

in aging infrastructure that has

43:51

served us to date without

43:53

thinking about the role of

43:56

new and increasingly affordable technologies

43:59

like batteries. batteries or

44:01

energy storage systems to

44:03

meet that charge, especially

44:06

as they become more accessible

44:08

and distributed and therefore can

44:11

help promote equitable, affordable

44:13

access to

44:15

more energy service customers. Yeah,

44:18

it's not that far removed from where

44:20

I sit now to think about how

44:22

battery supply chains matter. Starting

44:29

up this season, we're going to visit

44:31

all the steps in the battery supply

44:33

chain from mining to processing to manufacturing

44:35

to recycling. And we'll ask,

44:37

what are the benefits and trade offs

44:39

for the economy, the environment and human

44:41

well being? The

44:45

big switch is produced by Columbia

44:47

University's SIPA Center on Global Energy

44:49

Policy in partnership with Latitude Studios.

44:52

If you appreciate the reporting and storytelling that we're

44:54

doing here, you can rate and review the show

44:56

at Apple and Spotify. And you can

44:58

also send a link to a colleague or a friend who you think

45:00

would like it. You can find all

45:03

of our back episodes along with this current

45:05

season wherever you get your pods. The

45:07

show is produced by Daniel Waldorf, Mary

45:09

Catherine O'Connor, Ann Bailey and Stephen Lacy.

45:12

Ann Bailey is our senior editor. Sean Mark-Kwan

45:14

wrote our theme song and makes the episode.

45:16

And thanks to Austin Cope for field producing.

45:19

A special thanks to our Columbia team,

45:21

Harry Kennard, Natalie Volt, Koo Lee, Jen

45:23

Wu, Liz Smith and Tom Warrenhouse. This

45:26

show is hosted by me, Dr. Melissa Lott. Thank

45:29

you so much for listening. Stay tuned

45:31

for episode two next week.

From The Podcast

Columbia Energy Exchange

Columbia Energy Exchange features in-depth conversations with the world’s top energy and climate leaders from government, business, academia and civil society. The program explores today’s most pressing opportunities and challenges across energy sources, financial markets, geopolitics and climate change as well as their implications for both the U.S. and the world.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

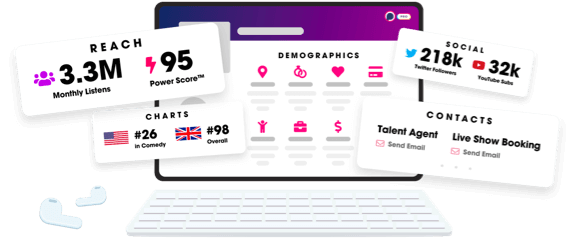

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us