Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Hi.

0:01

This is Graham Class, producer of the

0:03

Daily Dad Jokes podcast. You may

0:05

remember me from such episodes as Daily

0:08

Dad Jokes Explained Anyway,

0:11

coming up as an episode from my other

0:13

podcast, Technically Speaking and

0:15

Intel Podcast. I hope you enjoy

0:18

it. But before I go, here's a

0:20

dad joke I heard at the

0:22

local factory. The management is replacing

0:24

all their janitors with robots.

0:28

Talk about making sweeping changes.

0:35

Take a second to think about every single

0:38

item in your home, your television,

0:40

your refrigerator, your death lamp,

0:43

your laptop, even the smartphone

0:45

you might be using to hear my voice right

0:47

now. All of these things and

0:50

so many more items in our lives began

0:53

in a factory. There

0:55

are more than six hundred and twenty thousand manufacturing

0:58

businesses in the United States right

1:00

now, responsible for nearly twelve

1:02

percent of the total US economic

1:04

output. The numbers are even more

1:06

staggering in China, which makes up

1:09

nearly twenty nine percent of the total

1:11

global output. For manufacturing. Factories

1:14

have been around since the late eighteenth century,

1:17

and today they're used everywhere from

1:19

South Korea to southern California

1:21

to make cars, airplanes,

1:23

textiles, and even space vehicles

1:26

and each one depends on a carefully

1:29

choreographed system of steps, each

1:32

one as essential as the next before

1:34

the final product rolls off the production

1:37

line. Mistakes, however,

1:40

are also an unavoidable part of this process.

1:43

Manufacturers simply can't check every

1:45

piece of every product, and

1:48

it's nearly impossible to achieve perfection when

1:50

some manufacturing plants produce thousands

1:53

of items a day. So

1:55

how can technology help an industry so

1:57

crucial to our daily lives? How

1:59

canactories use AI to reduce

2:02

and even prevent defective products?

2:07

Welcome to Technically Speaking, an Intel

2:09

podcast produced by iHeartMedia's

2:12

Ruby Studio in partnership with Intel.

2:15

In every episode, we explore how

2:17

AI innovations are changing the world

2:19

and revolutionizing the way we live. Hey

2:23

there, I'm gram class, and

2:25

today we're headed into the world of manufacturing,

2:28

an expansive and essential industry that

2:30

drives the global economy and boast

2:32

the history dating back nearly two hundred

2:34

and fifty years, we've seen manufacturing

2:37

create a revolution, resurrect nation's

2:39

economies, connect people around the

2:41

globe, and even send mankind

2:44

into space. But what's

2:46

next at the intersection of manufacturing

2:48

and technology. In this episode,

2:51

we'll be focusing on how AI technology

2:53

can help optimize manufacturing and

2:55

improve quality thanks to no small

2:58

part to the minds at Intel and at our Innovations,

3:01

a company committed to helping organizations

3:03

unlock the power of machine vision to

3:05

automate quality inspections. Before

3:08

we go any further, let's welcome our guest

3:12

joining us today is John Weiss, the chief

3:14

revenue Officer at Eigen Innovations.

3:17

John oversees all revenue generation activities

3:19

at Eigen, including driving sales

3:21

in Eigen's machine vision software and engineering

3:24

services.

3:25

Welcome to the show, John, Thanks for having me, Graham,

3:27

it's great to be here.

3:32

Let's start with a bit of background on manufacturing

3:34

and the role it plays in our society.

3:36

I mean, it's fair to say that I phone, our car,

3:38

laptop, even the food we eat involves

3:41

some sort of manufacturing process. I'd

3:44

like to get your thoughts on just the importance

3:46

and scale of manufacturing plants around the world.

3:49

Yeah. Sure, Well, like you said, just

3:51

about everything in our daily lives comes

3:53

from factories or plants. But

3:56

sure, depending on if you commute

3:59

on a train or in a car,

4:01

lots of those components are coming from factories.

4:03

Very little these days are really kind

4:05

of handcrafted and handmade and small

4:08

batch, especially large scale

4:10

consumer items. And there's many

4:12

different types of processes and many

4:15

different types of ways things are made.

4:18

And look, I know there's a

4:20

multitude of ways and types

4:22

of manufacturing processes.

4:24

Like a volkswag And built in Germany is going

4:26

to be very different from an iPhone built in China.

4:30

Do you find common threads or

4:32

similarities across manufacturing

4:35

industries.

4:36

Yeah, definitely, so, I guess maybe

4:38

as a kind of a starting point, it's important to understand

4:41

there are two types of manufacturing processes

4:43

or approaches. One is called process manufacturing.

4:46

This is things like chemicals, plastics,

4:49

things that can't really be broken down

4:52

or deconstructed easily. Or

4:54

you have discrete manufacturing, which

4:56

is much more of the process of putting stuff together.

4:59

Think about a watch or a car. Now,

5:01

both of those processes, discrete and process

5:04

manufacturing, they're quite different,

5:06

but there are certainly similarities.

5:08

And between the two methods. You basically

5:10

have all of the things that we use every day,

5:13

right then oftentimes actually they kind of

5:15

bleed into one another. Most things have a little bit

5:17

of process manufacturing involved, and then a little bit

5:19

of discrete manufacturing as well. However,

5:22

I would say the commonalities across

5:24

both are really heavily reliant on technology.

5:27

We see a very large push for data

5:29

driven decision making. We

5:32

see large patterns or trends

5:34

in both realms of manufacturing around

5:36

empowering the workforce, trying

5:39

to upscale workers via technology

5:41

to get them to be focused

5:43

on more mission critical tasks or

5:46

higher value activities while

5:48

letting some of the technology do more of the mundane

5:51

tasks.

5:52

Yeah. In a previous job that I had, we

5:54

were doing consumer electronics, and

5:57

we struggle quite a bit with

5:59

the quality side of things, sure, and being

6:01

able to ensure a good product

6:03

can you manufactured in our China plant?

6:06

And one thing that struck me was

6:09

that there was a very manual process

6:11

in terms of the quality inspection, and

6:13

it'll take samples in a one out of every

6:16

ten and they'll test that and then if that worked

6:18

and okay, then we assume the rest kind

6:20

of work. Right. I'm wondering if you

6:22

could share any stories or examples

6:24

of I guess problems with quality

6:27

or defective products that stick in

6:29

your mind. Yeah.

6:31

Absolutely, I mean that's all we do at AIGEN, right,

6:33

all we do is industrial machine vision

6:35

for inline quality inspection. So

6:37

a couple that stick into my mind actually

6:39

very relevant to what you said, sample testing.

6:42

Lots of manufacturers do this right if there are a

6:44

high volume shop or a high volume

6:46

process. For example, we have some

6:48

customers that use our technology to inspect

6:50

upwards of forty thousand units a week per

6:53

facility. The challenge is if you do find

6:55

a problem, now you're kind of scratching your head

6:57

wondering how many in between the last

6:59

one hundred or last fifty also

7:01

had a problem right, And unfortunately

7:04

you tend to find out the hard way when

7:06

you get returns or warranty claims

7:08

that maybe something wasn't right in that process.

7:11

And so technology is a great

7:13

way, especially the arena that we operate in computer

7:15

vision, we're helping customers

7:17

actually get away from that. A great example

7:20

is one of our manufacturing customers

7:22

who makes fuel tanks for a variety

7:24

of different vehicles, and

7:27

they do what's called destructive testing. They

7:29

don't just test, they actually break the fuel

7:31

tank, that cut it up, and they look

7:33

at all of the plastic components inside

7:35

and they see was it molded correctly, was

7:37

it welded correctly? And if

7:39

they have a problem, well, now they have to reverse

7:41

engineer a whole bunch of stuff and try to figure out,

7:44

holy cow, what went wrong? Right? And how do

7:46

we ensure that no bad fuel tank gets

7:48

on a truck. They started the journey with

7:50

us about three years ago, and fast forward today,

7:52

we're builts back on every new machine

7:54

that gets put into those plants for fuel

7:56

tank inspection. So they know unequivocally

7:59

every single product that they ship

8:01

out the door is of the highest quality standard

8:04

and if it's not, if something happens, now

8:06

they have complete traceability on everything

8:08

they've made, so they can figure out exactly

8:11

what went wrong in the process.

8:14

What John is talking about here is the output

8:16

of the manufacturing process. How can

8:18

we ensure every fuel tank that leaves

8:21

the plant will work as designed? Just

8:23

as importantly, we need to consider the quality

8:26

of the input components. Everything from

8:28

the greater steel to the precision

8:30

of the fuel gauges. These need

8:32

to be inspected to ensure that these are

8:34

up to the manufacturers standard. I

8:37

asked John for his thoughts about this.

8:43

We don't often look at raw material,

8:45

although it's possible in some cases, but

8:48

more often than not, are inputs that

8:50

we're looking at. It's actually process inputs

8:52

or parameters. So we're looking at feed

8:55

rates of raw materials, temperatures

8:57

of raw materials, things like this

8:59

and thes that become more of a scientific

9:02

look of what's happening on the assembly line

9:05

and ensuring that everything is inspect

9:07

We don't just look at the output of

9:10

you know, did you make a good or bad product, but we'll

9:12

actually show you all of the process data that

9:14

went into making that product. The

9:16

other side is on the discrete world,

9:18

where you're actually assembling things. In

9:21

this instance, what we do is we'll actually

9:23

monitor the assembly. So we'll look

9:26

at how people are placing door

9:28

panels into a doorframe,

9:30

for example on an automotive asset,

9:32

or look at tail lamps for

9:35

lighting purposes right the way that they're assembled

9:37

and put together. And what we can

9:39

do in real time is tell folks, hey,

9:41

what you're putting together is misconfigured, or

9:44

it's missing components, or it has too

9:46

many components. Those are defect

9:48

types that are pretty common in the assembly world.

9:51

And what are some of the technology that

9:54

is used for that? Is it vision? Is it sensors,

9:56

is it combination?

9:58

Everything we do is vision based so

10:00

we don't make cameras. By the way, we are a software

10:03

provider, we also act as a system integrator,

10:05

so a large part of our business is actually

10:07

delivering turnkey solutions,

10:09

not just the software. But we don't

10:11

make hardware, which is actually really

10:13

cool for us because that means we get to use

10:16

tons of different types of options that

10:18

are available for our customers and it

10:20

helps us really find the perfect

10:23

design and configuration that is

10:25

definitely going to solve problems. And

10:27

so having the flexibility is really nice, and of

10:29

course that's a large reason why we

10:31

partner with Intel. We're

10:33

built on the open Vino tech stack, and that

10:36

means we can run our software

10:38

really on any device that leverages

10:40

an Intel chip, which gives us tons

10:43

of options for deployments. What's

10:45

really cool about this though, from a quality perspective,

10:48

is that it means you now have one vision system

10:50

that can integrate with different types of

10:52

sensors. So if you want to do

10:55

say an optical inspection

10:57

for surface defects like scratches and dents,

11:00

but you also want to look at perhaps

11:02

inside that product in a thermal application,

11:05

if it's a molded part or something like that,

11:07

well you can look at all those different types

11:09

of sensor in one easier to use

11:11

screen right, So it removes

11:13

the headache of having to have five six different

11:16

vision systems to do a variety of inspections.

11:18

And I'm also interested in

11:20

the deployment of these sorts of new

11:23

technologies. I'd like to get your

11:25

thoughts and experiences around what's some of

11:27

the tips and tricks for people out there

11:29

trying to deploy not just for manufacturing

11:32

quality, but technology and AI in

11:34

general into a workforce that

11:36

maybe is a little bit hesitant.

11:38

Yeah, humans don't like change, that's for sure.

11:41

I know I don't. I'm guilty of that. And it's

11:44

certainly like that when you go into a

11:46

factory and you've got folks that have been

11:48

on the same line or in the

11:50

same steel plant for

11:53

twenty five thirty years, and

11:55

you show up and you've got this bright, new shiny

11:58

software and you say, hey, don't worry, data

12:00

is going to solve everything. Naturally, people

12:02

can be quite apprehensive. We don't

12:05

often run into technology challenges

12:07

anymore.

12:07

Now.

12:08

It's really we run into people challenges

12:10

and organizational challenges. So

12:12

first and foremost, I'll give the advice that I give

12:14

on most of the times I'm asked this question, but it's

12:17

so true. Is you don't ever

12:19

start adopting technology just

12:21

for the sake of adopting it, just because

12:23

competitors are using something, or just because

12:25

somebody wigh up the chain says, hey, we need an AI strategy,

12:28

Go invest in AI boom. Spend

12:30

some time and really think about the problems

12:33

that you're trying to tackle. In my world,

12:35

in the quality world in manufacturing, it's

12:37

looking at things you can do to increase yields,

12:40

increase your throughput, reduce your waste,

12:43

reduce your rework, and ultimately

12:45

lower what's called the cost of quality.

12:48

Start with that, find a way that you

12:50

can or process that you can optimize

12:53

by using some of this newer technology, and then

12:55

of course do a cost assessment or

12:58

a return on your investment analysis, and

13:00

ensure that the business justification is there.

13:03

My experience, that's where a lot of these projects

13:05

fall short, and where folks get stuck in

13:07

these pilots and pocs is because

13:09

they get really excited to try something,

13:12

but there is no proven business

13:14

value or business justification behind

13:16

it, and naturally then you don't get

13:19

the executive sponsorship you need. Your budget

13:21

falls through and the project goes nowhere.

13:23

And in your experience, what industries do

13:25

you find actually a

13:28

little bit more advanced in terms of adopting

13:30

these new technologies both on a

13:32

technical level but also at an organizational

13:34

level that it seems like the teams

13:36

are actually involved and successfully

13:39

deploying these sorts of techniques.

13:41

Yeah, that's a great question. We see pretty

13:44

advanced deployments in the automotive world

13:46

as far as discrete manufacturing goes. They

13:48

tend to be far ahead of the curve compared

13:51

to say steel manufacturers

13:53

or something like that, or concrete manufacturers.

13:56

There's a lot of very advanced technology and

13:58

those automotive facilities that make sure what you

14:00

buy is actually perfect. Similarly,

14:03

in the process world, pharmaceuticals

14:05

tends to be on the continuous process side

14:07

that tends to be pretty advanced. They have

14:09

a lot of vision systems in place looking at

14:12

the vaccine vials to ensure

14:14

the integrity of vile caps and seals

14:17

and things like that. Some of the laggers

14:19

would be metals, some of the plastics

14:22

organizations. But there's also

14:24

a kind of a bigger dynamic in manufacturing that

14:26

I think folks don't really understand

14:28

that also contributes to who's advanced

14:31

and who's not, which is the

14:33

sheer size of these organizations,

14:35

right, Manufacturers are not all large. Folks

14:38

tend to think about John Deere and three M

14:40

and you know, the largest players

14:43

in the world, and the reality is that makes

14:45

up such a small fraction

14:48

of the manufacturing pool. Especially

14:50

in America, most manufacturing facilities

14:53

have you know, twenty people or less, small

14:56

to medium manufacturers anywhere

14:58

from say like the twenty to two hundred range employees.

15:01

That's who makes up the vast majority

15:03

of our products. Even when you buy something

15:05

really big, you know, whether it's a whirlpool dishwasher,

15:08

or a hot tub or whatever it might be, all

15:10

those little components that make up

15:13

that consumer good, Well, it came from

15:15

probably many different suppliers, and most

15:17

of those are small.

15:18

It's nice that you mentioned that because my father

15:20

has a small manufacturing facility

15:23

here. And just to talk a little

15:25

bit more of the technology stack

15:27

that you're using with open Vino and Intel's

15:30

edge devices. I'm really interested

15:32

to see how some of the smaller guys can

15:34

actually use this sort of technology

15:37

so that it can actually be more competitive.

15:40

Sure, well, leveraging open Veno helps

15:42

us have a real wide range of how

15:45

on the hardware side, how we can install our

15:47

software. What that means for

15:50

smaller manufacturers is that we

15:52

can be quite flexible in the design

15:54

of a system and can accommodate just

15:57

about any budget, which that

15:59

alone is pretty significant to understand.

16:01

I still think there's a misconception that it's

16:03

too expansive or too cumbersome

16:06

for the little guys, so to speak, to really

16:08

innovate in their plants, and it's

16:10

simply not true. You know, we have customers

16:12

that make as little as twenty parts

16:14

of shift, and even

16:17

for them, having the flexibility of how

16:19

we design and configure these systems, it ensures

16:21

that even they can embrace newer technology

16:24

and provide the highest amounts of quality

16:26

to their customers.

16:29

Part of the reason i Can can design and configure

16:31

those systems is because the company uses

16:33

Intel's central processing units

16:36

or CPUs, as opposed to

16:38

GPUs, or graphics processing

16:40

units. GPUs are

16:42

specialized processes are allegedly

16:45

designed to accelerate graphics rendering.

16:47

The key difference in the manufacturing world is

16:50

that CPUs, like the ones Intel

16:52

provides for Iigen, are able

16:54

to perform under harsher or hotter conditions

16:57

like the ones you might find in a factory or factory

17:00

plant. GPUs, meanwhile,

17:02

are prone to overhitting without the use

17:04

of a fan to cool it down, and most

17:06

factories won't use fans so they

17:08

can avoid spreading dust and debris.

17:11

There's always a tradeoff between designing software

17:14

optimized for CPUs or GPUs

17:16

and a manufacturing plant. I

17:18

asked John about this, and I found his answer

17:20

to be quite illuminating.

17:24

It's always an interesting discussion when people ask

17:26

why don't you just go on GPUs and what's

17:29

the real difference? And from

17:31

a manufacturing perspective, just

17:34

logically thinking about what happens in

17:36

a plant. If you remember, like

17:38

late nineties, you remember you had your Compac or

17:40

your Gateway PC, this big old

17:42

white box on the floor, and every

17:44

so often you take the front panel off and it

17:46

would just be totally caked in dust.

17:49

Right, You'd hear the fans humming,

17:51

and well, this is what happens

17:53

to GPUs and factories. This is why

17:55

we don't use fans, because factories

17:58

are dirty. There's dust everywhere.

18:01

And what we found is that when

18:03

we explored using various types

18:05

of mediums, to do our processing. What we found

18:07

is that fanless Intel

18:10

boxes were not only

18:12

just as performant and in some instances probably

18:14

even more beneficial to use. But on

18:17

the maintenance side of it, we

18:19

didn't have to worry about dirt

18:22

and debris, which exists in every single

18:24

plant that we deploy these in. We also

18:26

didn't have to worry about heat. GPUs

18:29

generate tons of heat. I

18:31

had this discussion with somebody who did

18:33

deploy GPUs in a manufacturing environment,

18:35

and they were looking at in tens of millions

18:38

of dollars in HVAC improvements just

18:40

to keep the factories cool enough to

18:42

operate effectively. Right. And then the flexibility,

18:45

like I mentioned, being able to very easily

18:48

scale the hardware for more

18:50

advanced use cases. If we need two or three

18:52

different edge boxes, it's really easy to

18:54

do, and also be able to scale down

18:56

for the smaller applications where we want to make it

18:59

a bit more cost factor for the smaller

19:01

manufacturers as well.

19:04

Coming up next on technically speaking

19:06

and Intel podcast.

19:08

Computer vision specifically for quality is

19:10

becoming more and more common. I think this

19:12

will become completely commonplace

19:14

over the next twelve years.

19:16

We'll be right back after a brief message from our

19:18

partners at Intel.

19:25

Drive away in a new NG this

19:27

end of financial year. The full MG

19:29

range is on offer, including the MGHS

19:32

Essence Suv with a panoramic

19:34

sunroof, sports seats and advanced

19:37

safety tech from just thirty three nine ninety.

19:39

Or get the MG ZST, a

19:42

compact SUV with sporty alloy

19:44

wheels and a ten point one each screen

19:46

from just twenty five four ninety Drive

19:48

away. Speak to your local MG dealer

19:51

to drive away in a new MG this

19:53

end of financial year.

19:58

Welcome back to Technically Speaking, an

20:00

Intel podcast. I'm here now with

20:02

John Weiss. I'd

20:06

actually like to get you to talk a little bit about

20:08

Eigen Innovations. If you could tell

20:10

us a little bit about the company and

20:13

its mission.

20:14

Sure so, Iigen Innovations has been around

20:17

for twelve years. We

20:19

started in academia out of the University

20:21

of New Brunswick. It was founded by a PhD

20:24

student and a professor. We

20:26

started as a system integrator, so we were

20:29

going into factories actually installing vision

20:31

systems, and over the course of about

20:33

a decade we developed our own software

20:36

to make our job as a system integrator

20:38

easier and about I don't

20:40

know. Two and a half years ago or so, we realized

20:42

there's actually a ton of value in IP

20:45

and software we created, and

20:47

so we reinvented the company and moved

20:49

away from leading as a system integrator

20:52

to actually leading as a software SaaS

20:54

based company. We really only do

20:56

one thing. We do inline quality

20:58

inspection, and actually, to more specific,

21:00

our specialty is thermal applications

21:03

that leverage AI. So when

21:05

you think of like injection molding,

21:07

blow molding, metal welding, plastic

21:10

welding, void detection, and

21:12

plastic goods, anything that has

21:14

a heated process that the human eye

21:16

can't easily see defects. We

21:19

do really really well there.

21:21

And we talked a little bit about AI,

21:23

and I think we've also talked about

21:25

the software that utilizes

21:27

machine vision. Where do you see

21:30

AI models and the CPU based

21:32

technology being able to compete

21:35

with machine vision use cases?

21:37

Yeah, it's a good question. Look, I think there are pros

21:39

and cons of both approaches. We

21:42

actually have not yet come across

21:45

a project that we had

21:47

any kind of processing limitation on being

21:50

CPU based. We have applications

21:52

in production running yet thirty

21:55

inferences a second across cameras,

21:57

right, that's quite quite fast.

22:00

There are definitely higher demand applications,

22:03

but in our world a process in discrete manufacturing

22:06

and the types of projects we typically

22:08

focus on, speed has

22:10

actually not been a problem for us

22:12

with CPUs, even at quite aggressive

22:14

speed. I see the tools getting

22:16

easier and easier to use, more

22:19

and more self service, if you will.

22:21

Years ago, we had this phrase of democratizing

22:24

data, if you remember that, around the days of big data,

22:27

kind of empowering everybody to be a data scientist,

22:29

and I see the same movement

22:32

happening in the AI world. In fact,

22:34

actually we're a good example of that. You can use

22:36

our tool to build deploy train models

22:39

across factories and you don't

22:41

have to touch a line of code. So I think that's

22:43

the future. I think the tools get easier and easier

22:45

to use, so that my good

22:47

friend Jimmy who's down in Texas at

22:49

one of our customer plants, who's been in that same

22:52

plant for over thirty years, that

22:55

he can blow me away with how he can build

22:57

a model that does thermal inspection on metal

22:59

wellness, and years ago, somebody

23:02

that didn't have that kind of training from

23:04

a data science perspective or a programming

23:06

perspective, they would never be able to do that, and

23:09

today they're building dashboards

23:11

and building models that are literally

23:13

redefining the way these manufacturers operate.

23:15

It's amazing.

23:18

You heard John say earlier that Eigen has been

23:20

around for more than a decade and this technology

23:23

has been implemented across a variety of manufacturing

23:25

spaces to thermally inspect items

23:28

like metal paper, cardboard,

23:30

box adhesive, automotive windshields,

23:33

and high glass plastics. With

23:35

such a lengthy track record of achievements,

23:38

John spoke about one specific company success

23:40

story that stuck out for him.

23:45

A couple that come to mind. I mentioned

23:47

we inference about thirty images per

23:50

second in this one process. This is a paper

23:52

process, so it's continuous, very

23:54

high speed, and it's for a high

23:56

glass specialty paper. And

23:59

what happens is the high gloss coating

24:01

goes on the paper very rapidly as it's going

24:03

down the line, and unfortunately

24:05

there's a problem where this coding can

24:07

build up and if it's not caught in about

24:09

eight seconds, it will do roughly one hundred and

24:11

twenty thousand dollars worth of damage to the equipment.

24:14

This can happen multiple times as shift. This

24:17

is a very expensive problem if it's

24:19

not caught. And so this one's a great

24:21

example of a thermal application. It's a heated

24:23

coating where we look at that we inference, like

24:25

I mentioned about thirty images a second, and

24:28

in just about one second, we look at

24:30

all of those images, we make a determination is

24:32

there a problem or not, is it good or is it bad?

24:35

And we actually do close loop automation

24:37

as well. We'll send a signal back

24:39

there and trigger a stoppage on the line to avoid

24:41

equipment failure. All of that happens

24:44

in less than one second. So that's a really

24:46

good example of speed. Another good example,

24:48

I'll give you just one more in the interest of time. How

24:51

we can help see things that folks can't

24:53

see. Well, I mentioned fuel tanks,

24:55

and I mentioned some plastic components

24:57

and things like that earlier. Naturally we

24:59

use thermal vision for that humans

25:02

can't see in thermal patterns, of

25:04

course, so we're able to show quality

25:06

engineers inconsistencies in the product

25:08

that they would never be able to see with the human eyes.

25:11

One of our customers manufacturers the

25:13

front plates for a dishwasher

25:16

company. A very large dishwasher manufacturer. And

25:18

so if you've recently gotten a new appliance,

25:21

you probably remember you had to peel all that film

25:23

off, right. Well, what you might not know

25:25

is that film is on from the

25:27

raw material phase and what

25:29

happens is as it goes down the

25:31

process, it gets stamped like a cookie cutter.

25:34

But that film is on it the whole time

25:36

to protect it. So what's really tough

25:38

is for the quality engineers to actually see

25:41

through the blue film or whatever

25:43

tint it might be, to see if there's

25:45

a scratcher dent. And so this is one problem

25:48

we solved for one of our customers where

25:50

they were missing the dents. They were missing the scratches

25:52

because the humans simply couldn't see through the protective

25:54

film. Fast forward to today again,

25:57

another customer that inspects one hundred

25:59

percent of their production on our tooling and

26:01

gives them indicators in real time through

26:04

that blue film if they have any kind of service

26:06

defect.

26:08

And you've talked a little bit about the

26:10

Jenney twelve years ago to

26:12

now, I want to get you to cast

26:14

your mind ahead twelve years in the future.

26:17

Where do you think igen will be and

26:19

in general, where do you think manufacturing

26:22

and quality control technology

26:24

will be in the next twelve years.

26:27

That's a pretty far horizon. I

26:29

don't even know if I could guess the next twelve months,

26:32

to be honest with you, just because the industry

26:34

moves so fast. But let's say over

26:36

the course of the next decade, I would definitely see

26:38

some of the more innovative technologies becoming

26:40

mainstream. So computer vision, there's

26:42

no doubt about it. Computer vision, specifically

26:44

for quality is becoming more and more common.

26:47

I think this will become completely

26:49

commonplace over the next twelve years.

26:51

Often ask this of our guess, but if

26:54

you could have AI solve one thing

26:56

in your field that is manufacturing,

26:58

what would it be.

27:00

I would like to use AI to clone the

27:02

entire Eigen team because these are some

27:04

of the most talented people I've ever worked

27:07

with, and I just need like three to four

27:09

times more of them so I can go take over the world.

27:11

Yeah. Well, we did have an episode

27:14

on digital twins and have

27:16

a human digital twin, so yeah, you never

27:19

know. With that, I'll leave it there.

27:21

Thank you John for your time.

27:23

Well, thank you, this was great. Thanks for having me.

27:27

Thank you to John Weiss for his quality

27:29

insights in today's episode. Of technically

27:31

speaking, in

27:34

a world where we are somewhat preoccupied

27:36

with virtual and digital goods, I

27:39

love hearing stories about the production of real

27:41

world physical products. I

27:43

think we take for granted how much time, effort,

27:45

and brain power it takes not only to

27:47

conceive of new products, but to design

27:49

the whole manufacturing process and

27:52

get them into the hands of you, the customer.

27:55

John highlighted that quality is now non negotiable

27:57

for consumers and that manufacturers

28:00

need to continually reinvest in new technology

28:02

and methods to keep producing high quality

28:04

products as economically as possible.

28:07

A common theme in all of our episodes, and one

28:09

that I'm always exploring, is

28:11

whether these new advances in AI, like

28:14

the machine and computer vision discussed today,

28:16

will help all businesses, regardless

28:18

of size. So it's pleasing to hear John

28:21

say that their technology can help the smaller

28:23

niche manufacturers to use the same

28:25

quality control software and hardware that

28:28

the big players have. This is

28:30

why I'm so bullish about AI and technology

28:32

in general, the ability to lift all

28:34

people and businesses up, no matter

28:37

what stage of life they are in.

28:41

In our next episode, we will look at how we

28:43

can close the AI workforce. Gaut through

28:45

education. So join us on July second

28:48

for the next edition of Technically Speaking and

28:50

Intel podcast. Technically

28:55

Speaking was produced by Ruby Studio from

28:57

iHeartRadio in partnership with Intel

29:00

and hosted by me Graham Class. Our

29:02

Executive producer is Molly Sosher, our

29:05

EP of Post Production is James Foster,

29:08

and our Supervising producer is Nika Swinton.

29:11

This episode was edited by Sierra Spreen

29:14

and written by Nick Firshall.

From The Podcast

Daily Dad Jokes

On a mission to spread the laughs (and groans).Daily Dad Jokes Podcast - Dad jokes that are guaranteed to make you laugh and your family and friends groan! Top dad jokes are curated and produced daily. Sourced from the Dad Jokes subreddit on Reddit! Credits are in the show notes pages of each episode.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

- Official Episode Pageomny.fm

- Download Audio Filehttps://chrt.fm/track/5899E/podtrac.com/pts/redirect.mp3/traffic.omny.fm/d/clips/e73c998e-6e60-432f-8610-ae210140c5b1/b4a15fc3-aed2-4f7c-9e90-afb201043e83/45dbfb21-181c-45a5-9aaf-b19500fd7bbc/audio.mp3?utm_source=Podcast&in_playlist=78c847a0-e8ec-4de4-a334-afb201043eb2

Episode Tags

Claim and edit this page to your liking.

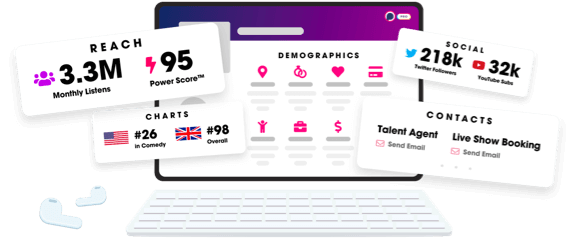

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us