Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:09

Welcome to the SOSV Climate Tech Summit podcast series.

0:13

I am the AI voice of Ben Joff, a partner at SOSV and co-curator of the Climate Tech Summit.

0:19

In a panel discussion moderated by Dr.

0:21

Sabria Stukes, Chief Scientific Officer at IndieBioENWI,

0:25

founders Beth Esbonet of Unspun, Gilberto Loureiro of Smartex,

0:29

and Onur Eren of Gozen discussed innovative approaches to sustainable fashion.

0:34

The conversation focused on leveraging technology to reduce waste and emissions in the fashion industry.

0:40

Beth highlighted Unspun's on-demand manufacturing model that minimizes fabric waste and promotes efficient production.

0:47

Gilberto discussed Smartex's use of advanced technology to enhance quality control and reduce defects in textile manufacturing.

0:54

Onur emphasized Gozen's development of new materials that offer sustainable alternatives to traditional textiles.

1:01

The panel also touched on the challenges of scaling sustainable practices and the role of government regulation in promoting industry-wide sustainability.

1:11

Welcome everybody to this session. Our moderator today is Sabria Stukes,

1:15

who is the Chief Scientific Officer for IndieBio in New York.

1:19

She knows all these founders well because they all happen to be SOSV portfolio founders.

1:23

So how we're going to roll today is essentially Sabria is going to run a 30-minute conversation more or less with our speakers.

1:32

And throughout that, you should feel free to put questions in the Q&A section of the Zoom.

1:38

So we'll be looking there for great questions that Sabria can start to throw at our panelists after about 30 minutes or so.

1:47

So for about the first 30 minutes, Sabria is going to run the conversation,

1:50

then we'll turn to some audience questions. And of course,

1:52

we encourage, Sabria was just saying earlier backstage,

1:56

a conversation here. So it's not just an interview format.

1:59

We're hoping that panelists will ask each other questions and join in the conversation broadly.

2:05

So with that, I'm going to pass it over to Sabria.

2:08

And thanks very much, Sabria, for moderating this session.

2:11

It's going to be great. Absolutely. Thank you so much,

2:14

Ned. And thank you so much to all of you who are joining us.

2:17

And so just want to reiterate what Ned was saying is please do feel free as the conversation is going to put your questions or even comments in the chat and hopefully we can get to some of them.

2:29

So given that we only have about an hour with these founders and I want to jump right into it.

2:35

And so, you know, when I was asked to.

2:38

To moderate this panel, I was kind of thinking, well,

2:41

kind of how can I ground myself or what is the foundation of which we can start this conversation?

2:46

And so I think for all of us, right,

2:48

it's no secret that clothes can be deeply personal.

2:52

They can be a way to help us express who we are and sometimes who we want to be and can be representations of pivotal moments in our lives.

3:02

Clothes are also items that can hold really strong connections to our past.

3:07

And I was reminded of a book called Worn.

3:10

Maybe some of you have heard of it. The actual full title is Worn,

3:13

A People's History of Clothing, which in 2022,

3:17

the New Yorker chose as its best book of the year.

3:21

They called it a sweeping and captivatingly told history of clothing and stuff it is made of,

3:26

an unparalleled deep dive into how everyday garments have transformed our lives,

3:30

our societies and our planet. And

3:32

I mostly raise this as an example because if you had told me maybe two years ago that one of the New Yorker's best book of the year would be about clothes,

3:40

given everything our world was going through, I would have felt maybe a little skeptical.

3:45

But as you can see,

3:48

many people feel very deeply about it. So while much has been written,

3:51

and I hope will continue to be written about the impact producing clothes has on our planet.

3:57

I am really excited to kick off this conversation with three founders who are tackling this problem from a variety of angles.

4:03

And so, as I was saying, as I was thinking about this topic,

4:05

I was reminded of the three R's. I don't know how many people remember the three R's of waste management,

4:11

reduce, reuse and recycle. And while that is a phrase I don't think I've said out loud since middle school,

4:18

it feels as though many of the efforts to combat consumerism,

4:22

overconsumption and maybe even think more sustainably,

4:26

could benefit from going back to this simple mantra. And so to kick it off,

4:31

what I would like to have is if our three founders could briefly introduce yourselves,

4:36

talk about your technology, and then we can dive into some questions.

4:40

Beth, why don't you go ahead and start? Amazing.

4:43

Thanks so much for having me here. My name is Beth.

4:45

I'm one of the founders of Unspun. We're trying to create an industry that's on demand.

4:52

So what we're doing is changing the way that clothing is manufactured.

4:56

I'm right now sitting in our microfactory in Oakland,

4:59

California, and we have three 3D weaving machines behind me.

5:03

We're trying to make it possible to take yarn and create final garment straight from yarn and skip the fabric cutting stage.

5:11

One big problem with going from yarn to fabric to final garment is it is extremely labor intensive and it requires a sewing machine.

5:20

So it's just very, very difficult to automate that process and then be able to.

5:26

localize production and kind of have a more responsible industry.

5:29

So I'll stop there without talking too much,

5:32

but in any case, I'm very excited to be here and to be talking to these awesome other panelists.

5:36

I'll pass it to Gilberto. Hey,

5:40

thank you Beth. It's a nice moment to see a 3D weaving machine here in the background.

5:46

I hope soon some cameras and computer vision systems will go there to avoid some waste in case we can help with some.

5:54

I'm Gilberto, I'm the co-founder of Smartex.

5:59

This whole started with an accident and a hate story.

6:02

Because when I was a teenager, I was promoted to be an inspection worker in a textile factory in my summer job.

6:10

And it's the most horrible job on Earth, is spending eight hours per day looking to fabrics rolls after they've been produced and mark defects manually.

6:18

And then I realized that like five to 10% of the production of normal garments are wasted because of defects in the manufacturing process.

6:28

And then when I knew about the margins of these guys,

6:31

Poor guys, like my clients, they have really tiny margins.

6:35

Like they have a few defects or a few garments wasted.

6:38

They need to produce like for days to recover the materials lost.

6:43

So we started developing a bunch of cameras and sensors and cool stuff to install in textile machines.

6:50

We have been very lucky and growing a lot in India,

6:53

Bangladesh, Pakistan, Turkey, Italy,

6:56

Brazil. We are installing cameras in all the factories of the world,

7:00

inside the machines, unfortunately not yet in California,

7:03

but Beth will take care of that. And we are basically saving tons of money and waste from our clients.

7:10

In parallel, we stumbled in a larger problem,

7:13

which is the overall lack of transparency and the overall lack of digitization of the industry.

7:19

So we are also installing screens and sensors and tablets and QR codes.

7:24

and help factories to really catch up with other industries and create the modern textile factory.

7:29

That's one of our missions at Smartex. Best to you,

7:32

Wander. Yeah.

7:34

Thank you, Gilberto. Thanks for having me here.

7:39

It's great to be with Bert Gilberto and talk about decarbonizing fashion today.

7:44

My name is Onur. I'm one of the co-founders of Gozen.

7:47

Gozen is a bio-creation company. We grow next-gen high-performance materials for product designers to make products out of it instead of animal-based materials.

8:04

Our production process is entirely bio-based and our first product is Gluniform,

8:11

which is a high-performance material that can be used in fashion.

8:16

instead of other animal-based alternatives.

8:19

I'll cut it short for now, but I'll dive into more into technology and how we do it with questions,

8:26

Sabria. Thank you. And actually one thing,

8:29

Beth, that you said that kind of I think would be nice to hear about is so you said you're based in Oakland.

8:34

Gilberto and Onur, I'm not sure exactly where you are,

8:37

but could all of you talk about the decision to grow your company in the particular location that you're at?

8:44

And... did that or does that geography impact,

8:48

you know, how big you can grow? Beth,

8:52

maybe you want to go first. I'm also curious about the Oakland choice.

8:55

This is a hard question because we also have a few team members in Hong Kong and part like Gilberto,

9:02

like starting to expand into other parts of the world,

9:05

looking at another spot in North America,

9:07

potentially another spot in Europe,

9:10

but growing hopefully at like a sustainable pace and not something where we spread out too thin and aren't able to focus our efforts.

9:19

But why Oakland? Why the Bay Area?

9:22

Well, we... there is a bit of a Kool-Aid in the air that you kind of being here.

9:28

And I really felt it when I moved to the Bay.

9:32

The first time was in 2012,

9:34

2011, 2012. And there's so much optimism here.

9:38

It's kind of a fuzzy thing, but it actually makes a huge difference because your employee pool is just so much bigger.

9:45

People want to dive in. They're very eager for like the unknown and trying new things.

9:50

And I think. That was something that was interesting about being in Hong Kong as well.

9:54

That was early on. Actually, in our HACS days,

9:56

we were in Shenzhen and Hong Kong. That's where we met.

10:00

Yes, exactly. just amazing places,

10:04

but I think the culture there is not as excited about,

10:09

you know, jumping into new things,

10:12

and there's, I don't want to call it a fear,

10:14

but there's just more pull towards,

10:18

like, things that are a little bit more solid, and so that's something here.

10:23

I think there's been pull towards LA,

10:25

there's been pull towards... New York,

10:28

of course, those are like more kind of fashion capitals than where we are here in

10:32

San Francisco area. But I think because we're such a technology company,

10:38

it makes a lot of sense to be here. Fortunately,

10:40

the internet is, it's just such a global world these days,

10:44

like we're all calling in from different places.

10:46

So I think that's also helped us a lot. If we were just in the Bay,

10:49

I think we'd be lacking on a lot of the fashion aspects.

10:53

Yeah,

10:55

I always divide the innovations in fashion in three categories,

10:59

which I think we kind of represent them here.

11:01

It's the material side, like recycled materials,

11:04

vegan materials, that sort of stuff. Then the production side,

11:09

which is like all the shit show in the middle, like the 20 factories in the middle for spinning,

11:13

knitting, weaving, embroidery, cutting,

11:16

sewing, whatever. I guess we are here,

11:19

kind of unspun as well. But then also the retail front,

11:23

like there are no returns or the on-demand,

11:25

no stock, which is also where unspun kind of fits.

11:28

So these three areas, they are kind of very well represented here.

11:32

And I would say. depending on where you are in these three areas,

11:35

that should really influence the decision of where you should be based or your team or your gravity center should be based.

11:43

Because for Beth, maybe it makes much more sense to be close to brands and New York and fancy places and lots of parties.

11:50

But for me, I need to be in Lahore,

11:52

Karachi, Dakar, Karam Amaraj and Istanbul,

11:55

right? So we should really place our cards and depending on where we have the activity.

12:02

We decided to have all our engineers in Porto.

12:05

We have now 130 engineers in Porto,

12:09

in Portugal. I would say that are here like four factors very important for that.

12:15

The talent, software talent, a bunch of software companies are in Portugal and moving there.

12:20

The country is like amazing, safe,

12:23

like it's super affordable. It's easy to convince people to join our company and move to Portugal.

12:28

We have 19 nationalities there. Then it is like

12:32

Textile Hub is very near to Portugal.

12:35

We have the second largest textile hub in Europe after Turkey.

12:41

So we can really go back and forth to factories and test things in the same day.

12:45

We ship and test in the same day because we have the factories right next to us.

12:49

Spinners, weavers, knitters, garment manufacturers.

12:52

And the fourth is close to my mom's foot.

12:55

and my mom lives next to Porto,

12:58

like two hours driving, and it was also influenced a lot in the decision of placing the company there.

13:03

Some investors wanted us to be in the Valley, but we found it a bit silly,

13:07

and my mom's food is far away. I'm sure your mom really will appreciate that answer.

13:13

Owner? And first of all,

13:16

I would like to say that Gilberto, there are also nice fancy restaurants and clubs in Istanbul,

13:20

Turkey as well. I forgot to tell you.

13:27

The second place is actually Istanbul. And in our second year,

13:31

we acquired a startup in Maslak in Istanbul.

13:34

So it's actually my second hub.

13:37

I have an apartment there. So I'm always between Porto and Istanbul.

13:40

I forgot to say that. Second place would be...

13:43

Yeah, Istanbul is where I come from and also Gozen is based in San Francisco and Istanbul,

13:48

Turkey. So part of our team here based in the Bay Area.

13:52

Obviously, I would say, I think whatever...

13:56

type of company or whatever technology you engage with,

13:59

Bay Area gives you access to capital and also great networking opportunities for business development as well.

14:07

So I think it's very advantageous to be based here.

14:10

But as Gilberto mentioned, in terms of manufacturing can scale up,

14:15

it's really important for a company like ours,

14:20

you have to have strategic advantage.

14:23

Somehow you need to be able to create an edge for your company to be able to scale up and also serve the brands.

14:29

In that sense, Istanbul made a lot of sense for us because all the founders of the company,

14:35

we know the geolocation. And obviously,

14:37

it's the heart of textile. I'm sure Gerberto would also confirm.

14:42

It is so close to Europe so that you can save a lot of emissions with transportation.

14:48

And obviously, when you look at...

14:53

When you look at the manufacturing map on Istanbul,

14:57

Turkey, you have great talent and access and know-how.

15:03

And know-how is very important because when you want to scale a new technology,

15:10

you need to also be able to borrow some concepts from the existing industry.

15:15

So like how can I also use the existing equipment,

15:19

machinery to be able to provide a quick adoption to fashion brands that you want to serve?

15:27

That's hard. Istanbul helped us a lot to develop our manufacturing corporations and where we are also actually building the next facility,

15:37

which I would like to share more based on the questions after this.

15:41

Yeah, and actually you already used a word that,

15:43

you know, I had a question about, you know, a little bit later,

15:46

but let's go ahead and touch on it now, which is scaling,

15:48

right? So in order to make as big of an impact.

15:53

as possible in our fight against climate and, you know,

15:55

decrease some of these numbers that we're seeing coming out of the fashion industry.

15:58

Scaling both not just your technology,

16:01

but your company at the right time is really critical.

16:04

And so as I was looking through each of your individual websites,

16:09

you know, Beth, I really like the way that you frame your mission of

16:12

Unspun's North Star is a 1% reduction in global carbon emissions.

16:17

Vega is how we get there. It's clear,

16:20

it's crisp, it's a call to action. And so can I ask each of you how you think about scale and how that impacts your decisions for the next steps of your company?

16:33

Yeah, I'll dive into that. And thanks for calling out our mission.

16:37

Yeah, it does clarify things when things get messy all the time,

16:41

right? And you have to just come back to, okay, what are we going after again?

16:45

That's what we're going after. Well, what are you going after and how are you going to do it?

16:48

Right, exactly. Many companies say the big picture,

16:52

but what is that tangible solution that will get you there?

16:55

Yeah, and doing the most recent LCA with GreenStory,

16:59

we found that our technology, if scaled up,

17:03

can reduce global or can reduce emissions in our industry by 53%.

17:08

And the reason for that, there are a couple of them.

17:11

One small reason is removing cut waste.

17:14

So when you lay out a piece of fabric, cut it up and turn it into a garment,

17:17

you have about 10% cut waste. That's the small bit that it kind of covers,

17:24

but it also covers zero inventory.

17:26

So our goal, we're not starting with this.

17:29

We did start with this with our brand, but We'll eventually get back to a place where we have zero inventory and can make a product as soon as a customer buys it.

17:39

But this gets back to our scale question. We that's that is our goal and why we started out.

17:46

But to get to bigger impact,

17:49

being able to address more of the industry more quickly,

17:53

we decided rather than focusing on all the smaller brands who want to do custom with us and want to do on-demand,

18:00

that we would go for the bigger brands in addition,

18:05

but focus on those a little bit more. So we have a few very large brands,

18:09

including Walmart, to try to get this out there as quickly as possible.

18:14

And for that, you can't, or it's challenging to say.

18:18

okay, we're going to completely flip your business model and do everything on demand.

18:22

So instead we said, we're going to commit to doing extremely large volumes with you,

18:27

but maybe you don't have to change your business plan immediately.

18:30

You can still do more just-in-time manufacturing,

18:33

cutting down their lead time significantly instead of someone purchases and then we produce it.

18:40

But the goal is to get there with Walmart.

18:42

And then the last part is trying to make a model that...

18:48

This is a word I can't stand using, but someone needs to come up with a replacement.

18:52

That's more circular. So how do we take what we put into the world and turn that back into another garment end of life?

18:59

And we're doing that kind of at the yarn level. And those kind of three aspects,

19:04

the less waste, the closer to zero inventory,

19:07

and the closer to circularity bring us to the 53%.

19:13

Cool. Gilberto, go next.

19:17

I forgot a bit what was the question. It's the mission.

19:20

It's just thinking about how do you think about scale?

19:24

How do you think about growing your company? How do you think about increasing what your technology can do so that it can have maximum impact on some of the challenges that we're seeing in the fashion industry?

19:36

Yeah, it's actually one of the arguments I use to attract talent is like,

19:39

if you work in this industry, and if you make like certain improvements in this industry,

19:43

you have enough credits to do like to fly and things like that.

19:49

As this industry is by far the industry that has the biggest impact in the world and emissions and things like that,

19:58

compared with the amount of technology that is inside this industry.

20:01

You have trillions of dollars being produced on top of pen and paper.

20:05

on planning with pen and paper, on phone calls,

20:08

and super untraceable. It is literally impossible for anyone in this call or anyone listening to this call to know exactly the source of everything that happens with their clothes before they bought it.

20:20

Where the yarns come from, where the fibers come from,

20:23

which factories were used, which processes were used.

20:25

No way you can prove that. And even if you can prove that,

20:28

lots of question marks on that data.

20:31

So it's the largest industry in the world with less penetration of technology.

20:35

For many reasons, the materials are complex, are subjective,

20:38

the fibers come from far away from everything, it's very manual in later stages,

20:42

the sewing process, so fashion brands were going always for cheap labor places.

20:47

So lots of reasons for that. And because of the prices are so low,

20:51

nobody has cash to buy technology for automation.

20:55

So that's the current state of the art.

20:58

The industry pollutes 20% of the global water.

21:01

20% of the water that is polluted in the world is because of the textile fashion industry.

21:06

One out of six people work in the textile industry.

21:09

Sometimes we don't realize the amount of people that is involved.

21:13

And nearly between 2% to 10% CO2 emissions come from this industry.

21:18

Nobody really knows how to measure this number because,

21:20

again, there are no ways to prove where your garments are made.

21:24

So, service, this is the stage. if you can improve

21:28

1% of this industry, oh yeah, you are going to create a dent in the universe.

21:33

And we always design everything in SmartX to think about scale,

21:37

not about you are going to sell it in Europe and then to Turkey and then to...

21:40

No, no, no, no. Let's think about this like immediately in Lahore,

21:44

Karachi, Coimbatore, Mumbai,

21:46

like all of these places where the big desktop factories are.

21:50

and we developed like all the cameras, the hardware,

21:52

everything to be very Lego type of mounts and very cheap as well,

21:58

very affordable for our clients. So they can, they can have ROI.

22:02

Of course we are all here. I think we are all surfing another wave,

22:05

which is the legislation wave coming. We can talk about that,

22:08

but we cannot make a business counting on legislation.

22:11

Otherwise our runway wouldn't get there. We need to find concrete pains in the factories that we can kill.

22:19

And if we do have time, I would love to kind of dive into what we think that what role government can and should play kind of in next steps of the fashion industry.

22:28

But I want to give Onar some time to share with us a little bit about,

22:31

you know, his thoughts on how he thinks about scaling goes in.

22:35

Yeah, sure. So in our case,

22:38

it is a little more complicated to explain clearly because the material we bring to the market is somewhere in between textile and leather.

22:47

So Lunaform looks and feels like animal leather.

22:51

It's so beautiful, gorgeous, but it's also super thin and it's super strong.

22:56

Therefore, our North Star is actually like bringing a material.

23:04

and giving it to the hands of product designers so that they can eventually stop using,

23:09

you know, the other materials that they have to use today.

23:14

So simply enabling them to...

23:20

design in a way that they can create impact also at scale through the materials.

23:26

So obviously it's a hard problem to solve because it is not something

23:35

to replace or, you know,

23:38

let me tell you in this way, if you, if you, if you try to replace something,

23:42

then your chances is so low to create impact at scale.

23:45

So it has to be something new and it has to be adopted.

23:49

Right. So therefore I would like to answer like scale up question in a way that how we can also scale up this thinking,

23:58

this mindset, also from consumer side,

24:01

how to adopt this thinking.

24:03

Therefore, actually, we also I put our website transforming minds through materials.

24:10

So simply, how do we transform our material world?

24:13

And it creates a transformational impact on the minds of the consumers at the end.

24:20

Then this is how can create a circular impact in preferences of consumers and then brands adopt these new materials.

24:29

And then we can start talking about creating impact at scale.

24:34

yeah these are my two cents and actually uh maybe if we can stay with you because you know as i've kind of started the conversation with this phrase of reduce reuse recycle um and you know with beth and with what beth and gilberto do you know reduce is kind of like what they you know their mantra and i feel like that phrase

24:53

doesn't fully capture kind of what you are doing with goes in which is actually asking not just consumers but i think brands you know designers you

25:01

to almost reimagine or rethink our relationship to biology as it relates to the material world.

25:08

So as a microbiologist, I love it.

25:12

I can imagine to your average consumer, it is probably a harder kind of a sell.

25:17

And so maybe, you know,

25:19

now if you could share a little bit about your technology,

25:22

kind of why microbes, you know, why synthetic biology,

25:26

and how do you go about speaking about working with microbes as a unique value proposition instead of a challenge or a hurdle?

25:34

And actually, I'll integrate one of the audience questions,

25:39

which is, you know, how do you overcome the cost challenge?

25:42

And again, just talking a little bit more about the technology that Underpins goes in.

25:47

Sure thing. So as you said, it is complex to explain as well.

25:53

And since like when you are developing a new technology and presenting it to the world,

25:58

you also, I think, need to be careful about how you communicate it.

26:03

If it's too complex, then you lose your audience.

26:07

And even like, you know, we got some feedback in terms of,

26:12

you know, like working with... With microbes,

26:14

what does it really mean? How do we work with microbes?

26:17

So at the core, we use fermentation technology,

26:20

which is a very old technology.

26:24

We developed a process where we use fermentation and also only utilize sustainable ingredients to advance the production of our raw material.

26:38

our raw material in fact looks very like skin,

26:41

animal skin. And then we developed processes to apply this material,

26:51

dry it and simply convert it into an end product that product designers can make a product out of it.

27:01

In this sense, we are also working very hard to

27:08

tell this story in a very easy way,

27:11

but also, you know,

27:15

why is this important? Why adapting such a technology by brands,

27:21

by consumers? So yeah,

27:25

like we are doing a lot of work on this communication,

27:31

but yeah, I mean, we will also like hear and see more as we launch with more brands on the go.

27:37

Yeah, and so I do want to come back to, you know,

27:40

launching with brands and working with brands, but could you touch a little bit more of what you're

27:44

about the challenges in terms of cost as it relates to scaling up a company that's really based on,

27:51

you know, making sure your bacteria microbes are happy.

27:55

Yeah, they are so happy. No worries about that.

28:00

The good thing is actually our founder,

28:02

Jay, has been working on this over five years.

28:07

She applied for the first patent and the way that our core technology allows us to make a really great reduction on the production costs.

28:16

So this is a unique advantage that Gozen has.

28:20

And along the way, we applied it to, you know,

28:23

like to our also,

28:25

you know, production facility. And we simply redesigned,

28:29

literally redesigned many processes to even lower the cost further down.

28:35

Because I think, like we discussed there was scale up,

28:39

but one of the core aspects of scale,

28:42

being able to scale up as a company, you also have to,

28:46

you know, find the right pricing on the market.

28:51

So when you bring something new to the market,

28:56

if you just bring a replacement and just charge a green premium on it,

29:01

then you have very low chances of success.

29:05

Instead, obviously, it is very usual for every new technology work.

29:12

the high end of the consumer. Brands first,

29:15

as you know, like all new technologies, Tesla also launched like SportCard at the beginning,

29:21

right? But eventually, you know, lowering the cost down,

29:24

matching the price that your partners can work with you together and also scaling up accordingly.

29:31

So having a plan since day zero, not only optimizing your technology,

29:36

optimizing your product, but also like

29:39

bearing in mind the costs and design your technology and processes accordingly.

29:45

I think this mindset, this is how actually,

29:48

this was also saying on the first day we entered in the bio as well.

29:52

So we have always thought about how we can lower the cost down when we scale this up.

29:58

And yeah, here we are. So we are.

30:01

And obviously then the geolocation, we can also tie this topic to where you are based.

30:05

obviously, like, you know, making right decisions in terms of logistics as well.

30:11

Yeah. And so a few of you have mentioned kind of working with brands and securing these partnerships,

30:16

because sometimes at a high level,

30:18

it can feel like when there are these conversations about capitalism or consumerism,

30:23

it is on the consumer to, you know, recycle their plastics or to mend their clothes or,

30:28

you know, don't spend as much. And while I think there is value in those conversations.

30:34

you know, how do you actually think larger brands or organizations should be working with companies,

30:39

you know, both at, let's say, the seed stage or even the stage that all three of you are at?

30:44

And, you know, can you talk to us about how those conversations start,

30:48

right? Beth, I know you talked about Walmart. Oner,

30:51

I know you have a partnership with Balenciaga. So

30:54

you know, how do those conversations start?

30:57

And kind of, you know, can you give some advice on our two other founders who might be wondering,

31:02

okay, I have this technology that I think could make a really big impact in the fashion world.

31:07

How do I make those connections with large brands that need to see it?

31:11

Go ahead, Ben. All right, go for it. I'll go for it.

31:15

Our industry is so interconnected and it...

31:19

is tempting to just work in isolation,

31:21

I think. And we actually did do that for a little while and to some extent sort of do still.

31:27

Like we have a D2C brand that we've been running for the past five years.

31:31

The reason we, we've always wanted to work across the industry.

31:36

That's always been our goal. But we brought up our brand to start because it can be really hard to bring other brands,

31:43

other partners on board with something new. especially if you have no name and you have nothing,

31:49

nothing really to show. So we're like, well, let's just build it.

31:51

Let's show it to them. So that's actually how,

31:54

how we brought it to the market. And from there partners like H&M tried it.

31:59

That was the way that we, that we pulled them in was not,

32:02

here's a little pitch on a table and here's a presentation.

32:05

It was come try our brand, try our custom fit jeans.

32:08

If you like them, let's chat. So that's how all of our first collaborations started.

32:13

And those were. ones all with custom fit.

32:16

So not changing the way that it's manufactured,

32:19

but changing how the patterning works.

32:22

So that's all on the software side, body scan to custom fit.

32:26

Did you feel like you had to start? how did the,

32:29

because, you know, like, we're obviously talking about kind of decarbonizing the fashion industry.

32:33

Do you feel like you had to, like, lead with that? Like, we built something that's good for the planet and also,

32:38

you know, is a product that you want, or was like,

32:41

hey, here's a product that you want, and by the way,

32:43

it is also good for the planet? Or are you finding,

32:46

and again, this is maybe for all of you, are you finding in some conversations you are surprised by,

32:51

I don't want to say how little, maybe larger organizations do you care about carbon emissions,

32:55

but... balancing what you lead with when you open these conversations.

33:02

Yeah, great question. I think when we were starting,

33:04

we wanted to say it would be sustainability driven,

33:07

but no, not at all. That's a very nice cherry on top.

33:12

Really, it's about the business and how can we make their businesses more efficient.

33:18

For when we were starting with the D2C for directly to the consumer,

33:22

the consumer wanted to first and foremost,

33:26

either have the convenience and not having to like look for sizes.

33:30

That was one. customer segment and another customer segment wanted like a really flattering gene that one that just looked really good on them right that's hard to find and then oh by the way we didn't make a couple other pairs of jeans in order for you to get this one because we have zero inventory it's just one-to-one so

33:47

that was just a nice to have for the consumer same thing with a lot of the brands we're speaking with there is one particular brand that we have partnered with and they have individual carbon

33:59

like tracking for all of their leadership,

34:02

which is amazing. Usually, you know, you're tracking wins on the business side,

34:06

but they're also tying those together. So there is a start to it.

34:10

I will say they are based in Europe. So that's,

34:13

of course, like where everything kind of starts progressive-wise for sustainability and thinking about the environment.

34:19

But it does trickle to the rest of the world.

34:23

So, yeah, we did start out with the D2C, brought in some of the brands through the D2C,

34:29

and have worked. I think that

34:32

Onar was talking about, like, starting higher end and coming down to the masses.

34:37

And that's similar to how we've been doing it.

34:40

And it's been fun to kind of show off what our technology can do from,

34:45

like, an aesthetic and functional standpoint with the more luxury groups,

34:49

like, working with. Eckhaus Latte we launched with them last

34:53

New York Fashion Week and we have another collaboration happening in Paris at the end of next month but it's really the like where we replace just the standard product is is like the Walmarts of the world so with that you don't really play around with like here's here are all the fun directions we could go in one

35:11

of the things that I really admire about unspun was really bold move is you guys created a brand

35:18

And now you are forced always to wear the jeans from your brand.

35:22

You cannot use other jeans, right? Yes. It's like the equivalent that we create a technology for textile factories.

35:30

And I will also create a textile factory to show other people how our technology works.

35:35

It's really a bold move. I don't know if it will be the right or wrong strategy,

35:39

but it was a bold move and good on that.

35:42

I just wanted to add a few things on the comments.

35:46

So I don't know if this will be a surprise for anyone,

35:49

but fashion brands don't really care about sustainability.

35:53

Okay. Absolutely. Can I pause there?

35:56

Because I think to your point, Beth,

35:59

because all three of you are so in it, that it's not a surprise to you.

36:03

But I think for many consumers, there's become a way that...

36:06

It has been talked largely on social media,

36:08

largely in my... Okay. I actually think people are surprised,

36:13

you know, and it's like, but, you know, there are these capsule collections that are all about sustainability.

36:17

It's not, you know, we use- Let me put the finger,

36:20

yeah. Let me put the finger on this topic. I love this topic,

36:22

okay? I don't know if there's any dirty little secrets you want to share now because it is being recorded.

36:27

I'm just saying if you could share a little bit more insight into-

36:30

It's fine, it's fine. I'm already burnt in the-

36:35

So fashion brands don't care about sustainability because-

36:39

guess what? Consumers also don't give a,

36:43

don't care about sustainability as well. So because we humans,

36:48

we are very consumers and we love our bodies and we love to look ourselves in the mirror.

36:52

When we go to a shopping experience,

36:55

we would prefer by far, and there are plenty of studies on this,

36:59

by far the style and the touch of the materials or the pieces that we are buying.

37:04

Then the second place is like, price if the sustainable dress is a bit more expensive,

37:10

like nobody will touch it. And then like there are a bunch of other reasons,

37:14

convenience, blah, blah, blah. And sustainability is like the reason number 11 in the list of our preferences.

37:21

So how can we be here demanding, oh,

37:23

fashion brands, you should be, because we don't pay one cent more for a shirt if the shirt is sustainable.

37:29

So this all starts in the masses.

37:31

That's where I believe the governments and the legislation can have a real impact there,

37:34

because the incentives are completely disaligned. So,

37:36

consumers don't care about sustainability.

37:39

They don't pay about sustainability. There is a huge say-do gap.

37:43

That's how brands call this term, like the consumer saying and doing.

37:47

There is a huge say-do gap. And brands also,

37:51

I'm not saying that they are the poor guys in the equation.

37:54

They have lots of responsibility and of course they can do lots of stuff,

37:57

but they are here trapped a bit. There is an amazing story.

38:01

A few weeks ago, a public company in Europe called Renew A Cell

38:05

from Sweden, they were recycling tons and tons of garments from the piles of waste and transforming it into brand new yarns.

38:16

So it was an amazing story, love story, but guess what?

38:18

It was 30% more expensive than regular polyester and cotton and things like that.

38:23

So consumers won't pay 30% more.

38:25

Fashion brands even invested in those companies. We also have investments from fashion brands.

38:31

We have investments from H&M, from Balenciaga,

38:34

Gucci, Caring Group, and from other groups.

38:37

But I'm not counting on them to save my business. And I shouldn't.

38:40

Because they have their agendas. They have their businesses.

38:42

Their business is to create the lifestyle,

38:45

brands, the goods that everybody loves.

38:49

Just on another... angle on this is

38:54

I really feel that first brands don't care about sustainability.

38:57

Consumers also don't care. Brands are not ready to work with startups at seed stage.

39:02

It's fine for us to work with brands at seed stage in some pilot projects with some sustainability officer there or some marketing guy over there.

39:11

But these guys will never touch their core business like purchasing,

39:15

mass production. It will take ages to get there.

39:19

So I would really advise careful on getting into the infinite loops of meetings,

39:24

endless meetings with endless people in fashion brand groups,

39:26

because that's a loophole that I have been stuck in.

39:31

Yeah. And so, I mean, I don't know if you have comments or insights,

39:38

you know, in working with Balenciaga or how you think about the consumer brand kind of innovative tech relationship.

39:48

So again, what you were saying earlier about how hard it is to potentially sell the story of how you're making your material to begin with.

39:55

No, and by the way, it's great. We started in our seed stage.

39:58

We have a pilot with Balenciaga. Trust me, we put the Balenciaga logo everywhere in our website.

40:05

But from that pilot to really mass deployment on the Balenciaga supply chain and so on,

40:10

it still didn't happen today. So

40:13

I think I want to draw a more optimistic picture here to better comprehend,

40:19

okay, like, what is the problem? What is the,

40:22

like, you know, what could be the solution? And most importantly here,

40:26

how can we contribute to the development of this solution?

40:31

So I agree majority of things that Gilbert and also Beth shared.

40:36

So expecting end customers to pay higher.

40:42

and changing their mindset on how they buy things,

40:48

it's a long-term problem we need to deal with.

40:51

And we don't have a magic wand that we can change this.

40:56

We know the consumer researches,

40:59

et cetera. So it's not going to change in the short term.

41:02

So when we face this relationship out into two phases,

41:07

this is how I see it, to be honest. At first,

41:11

like phase three, it is changing consumer minds.

41:14

So expecting people to pay maybe a little more.

41:19

Then this is phase three, but it's a long-term problem to solve.

41:23

Phase two is kind of empowering brands to adopt these new technologies at scale.

41:33

And then so that, you know,

41:35

we see more and more products made out of these new technologies using these technologies on the market.

41:44

And on the first phase,

41:49

as innovators, are we able to bring not a product as good as what is on the market today,

41:57

instead better than it is?

41:59

So. I'll give the same example,

42:03

but because it resonates very well on my side.

42:06

Before Tesla, we could only dream about golf carts when we think about EVs.

42:12

But Tesla made such a good job that now consumers want an EV car,

42:18

not because it is only sustainable,

42:21

but it feels great when you drive it.

42:24

I love the acceleration on the S,

42:26

for instance, right? So my motivation.

42:30

is not simply spending my money on a product because it's sustainable,

42:34

because it's better. So I think this is the real challenge here.

42:39

And we also, like we always discuss internally as well,

42:43

what kind of problem we are solving at Gozen,

42:46

for instance. This is, okay,

42:48

this is a technology problem to solve, but this is also a design problem to solve.

42:54

So how can you really make things more beautiful than it is so that people start adopting your solution?

43:02

So in this scenario, how this fits into our product development strategy.

43:09

So for instance, our challenges or our goal,

43:12

our ambition is when you wear a jacket made out of uniform,

43:17

does it feel better than real animal leather?

43:21

And in our case,

43:23

it is yes, like we love the feeling. So this is where we see the real challenges.

43:28

So I truly understand and I agree with all these propositions.

43:32

So it's gonna take time, obviously, like it is so expensive to build the first of a kind project,

43:37

we all know that. But then

43:41

I feel like also this is how... We should explain the problem in the right way to the relevant stakeholders and expect everyone to collaborate with us to solve each phase of the problem.

43:54

And hopefully along the way, we will all be successful because

43:59

I think everyone has more or less like same North Star here.

44:03

And this is the beauty of the game, I believe. And also like this is why I'm optimistic and hopeful.

44:10

Well, it's always nice to have maybe something to look forward to,

44:16

but also something that we know we still need to work on.

44:19

Yeah, exactly. I do want to make sure I take a moment and try to get some of these audience questions in while we still have a little bit of time.

44:27

And so I might try to mash a few of them together and see if we can make this work.

44:33

But one of the first questions, excuse me,

44:35

was. kind of that we have already answered of,

44:38

you know, can these markets tolerate a green premium?

44:41

And it seems like sometimes yes, sometimes no.

44:44

But how do you handle the interplay of your technology's economics and its actual promise as a decarbonization technology?

44:55

Beth, you want to go first? Yeah. And I think playing off of what owner was talking about with like presenting this in a positive light that no matter your customer,

45:05

whether they're actual consumers, the brands,

45:08

manufacturers, whoever, they're not going to be pulled by something that you're presenting as like a negative,

45:14

like, oh, you know, you're dealing with this.

45:16

Here's a slightly better thing, or even that costs more like we're not.

45:21

yeah, we're not seeing this kind of green premium be a pull at all.

45:27

Instead, it has to be presented as like, for example,

45:30

our actual customers. I know we've talked about consumers,

45:32

we've talked about brands, but our actual customers, similar to Gilberto,

45:36

are the manufacturers. So we are leasing our machines to manufacturers and they have,

45:44

similar to Gilberto with the

45:47

problem of margins being extremely small for manufacturing.

45:51

Like you look at what, what is a brand selling on the market?

45:53

They're going to, if, if they're lucky though,

45:56

they'll usually aim for like a 75% margin,

45:59

but that's insane. They'll, they'll end up at like 50,

46:02

if they're lucky 40, 40, 35,

46:04

more likely. That's huge compared to like many,

46:08

you know, manufacturers getting like a couple percent,

46:11

maybe so. Yeah. If they're,

46:13

again, if they're lucky. And so we're, we're presenting this as like,

46:17

you can take back more power by automating a lot of this process and creating when the,

46:24

when the brand needs it, not necessarily these huge,

46:27

these huge orders all with manual labor. And so you can look at more than 10%,

46:32

you know, margin for them because we come to them with like,

46:37

here's a contract that's already signed with the brand. lease these machines and here you are.

46:42

So I think that's one of the ways that we're able to get so much traction is to say like,

46:49

here's your business opportunity that hasn't really been available for you in the past because you've had to rely on these old sewing machines.

46:59

Yeah, I feel that as well. And I feel in general,

47:02

I might look a bit pessimistic, okay, but I think

47:07

I'm very optimistic about... We didn't say that,

47:09

Gilberto. We didn't say that. I'm optimistic about the future.

47:14

You should see my clients speaking about their futures.

47:16

It looks like a funeral. But I think it is really the best time in the world to work in this industry because it's definitely the one that is left behind.

47:26

If you go to an automotive factory or electronics factory,

47:29

you see robots, cameras, automation everywhere. And in a textile factory,

47:33

it looks like you traveled 20 years or 50 years back.

47:37

So it's really an amazing opportunity. I think the industry was not disrupted yet because some of the technologies were not there,

47:44

like the material qualities or even like the machine learning to analyze defects was not really there.

47:49

And even today we can argue, can a machine learning be as good as a person doing analysis of?

47:55

But I think we are definitely seeing some tipping inflection points there.

48:00

There has never been so much money invested in technology and decentralized in the world.

48:04

So a guy like me, I could raise 40 plus million dollars based in Portugal.

48:08

Like that was never possible to happen like 20 years ago.

48:12

So this is a cocktail, right? We have money from one side,

48:16

technology from the other side. We have talent like everywhere.

48:19

Now there has never been so much people working in tech,

48:22

software and so on. So these three things will be a cocktail.

48:25

And then this industry is so much left behind.

48:28

I think it's an amazing opportunity to work in it.

48:30

So if it is not now, I don't know where it's going to be.

48:34

And I think, you know, I know we have about 10 minutes left and I think it would be remiss if we didn't spend just a few minutes speaking about the role,

48:43

Giobertto, as you kind of raised earlier, that government and maybe new policies could and should be playing.

48:49

I mean, I think if you look at other sectors like,

48:52

you know, therapeutics or pharma or even like...

48:54

cultivated meat. You know, we are seeing these challenges with regulatory hurdles,

48:59

with customer adoption. And so I can imagine people think,

49:03

well, fashion, like you're just making clothes or you are,

49:05

you know, selling to manufacturers. What regulatory hurdles,

49:09

you know, could there be or what, how or why the government should be playing a role?

49:13

And I'm sure all three of you have thoughts on this.

49:19

We work very closely with Brussels, Eurotex and some other big groups that are lobbying or designing the next future laws for Europe and the US.

49:28

What are you seeing? The New York fashion fact as well.

49:33

So what we see is first the guys in Brussels have no clue how a textile factory works.

49:37

So what they are requesting is like a bunch of stuff that will never happen.

49:41

But on the other hand, we have the technology and tech guys and textile guys.

49:44

They are doing a great job and pushing for some legislations.

49:49

For example, three layers. First, knowing where your materials come from or like the path,

49:55

the factories they have been through. First layer.

49:58

And this is already a nightmare, okay? Because then you will need to point your suppliers and then your competitors will see your suppliers,

50:03

you will see your prices and nobody wants transparency.

50:06

Technology, when it kills transparency,

50:08

always creates shock waves, like taxis versus Uber,

50:12

right? The classic example. So first layer,

50:15

locations. Second layer, processes.

50:17

Which processes the garments have been through, the fabrics have been through,

50:21

the dyes and all of that stuff. And then the third layer,

50:24

only after these two are possible, you have the LCA.

50:27

how much water this shirt consumes, how much energy and how much stuff like that.

50:31

So then governments can tax things that come from air freight,

50:34

for example, or that are made elsewhere. And they can control that.

50:38

So that will be the three layers that everybody's getting ready to implement.

50:44

But as I said, I think we should make our business to really kill a real pain of our clients first.

50:48

And then the legislation will be giving us a little push and not really count with legislation because it can take forever.

50:55

yeah owner do you have any thoughts about conversations you've been having around this yep so apart from the fashion industry specific regulations and you know like expected uh you know

51:11

implications of the regulators.

51:14

What I'm thinking is, maybe it's a little bit speculation here,

51:17

but I think insetting is going to be really important for the upcoming years,

51:23

especially in Europe, for companies to develop strategies,

51:29

not only in their supply chain operations,

51:32

but overall. So simply insetting is, as an organization,

51:36

if you simply based on Based on how your operations is,

51:40

if you can simply implement the applications,

51:48

inherently reduce your emissions in your supply chain.

51:51

In this scenario, for instance, at Gozan,

51:54

Luniform. So for a brand to use linoform instead of an animal-based material,

52:02

then it drastically reduces their emissions.

52:05

And also, there can be crediting schemes in terms of,

52:08

you know, based on insetting. So similar to,

52:12

like, I don't know, maybe European emission trading system or something.

52:15

So therefore, on the high level,

52:18

I think there will be more and more regulations coming in terms of insetting.

52:23

And this is gonna... effect,

52:26

especially companies like us,

52:29

or adopting next-gen materials,

52:32

reducing the emissions drastically coming from the materials will be a crucial,

52:36

a critical point for brands to adopt.

52:42

So, yeah. Beth, any closing thoughts on that,

52:44

on this section? Well, we've been following a couple of different types of policies.

52:48

So in Europe, extended producer responsibility,

52:51

EPR policies, and then, like,

52:53

for example, France's zero waste ban. I think things that are related to not throwing out excess are ones that we're following in Europe.

53:01

And then we're really pushing for, I think Gilberto mentioned this,

53:04

the Americas Act here in the U.S. Of course,

53:06

there's the Fabric Act and the Fashion Act. Those are other ones that we're also very interested in.

53:10

But the Americas Act is huge.

53:12

It would be huge if it passes. And one big thing that it's really going after is the de minimis loophole,

53:20

which allows for, for example,

53:22

Shein Temu to push through packages that are under $800,

53:28

right, and not have to pay any tariffs on that. And that's why we've been paying $2 for our t-shirts.

53:33

It's absolutely insane that this exists.

53:35

I mean, they accidentally created this loophole again by increasing the cost or the $800 in 2016.

53:42

that's one we're very excited about and fingers crossed that will pass yeah and I you know again I know we only have about six more minutes left and I purposefully didn't bring up the phrase fast fashion or she didn't move because I feel like that um it

53:58

could go off on a tangent but if there's maybe

54:01

60 seconds worth of thoughts that you have about that industry at large um you know is that something that you could even you know kind of um

54:12

put together in 60 seconds, other than maybe they shouldn't exist.

54:16

I'd like to point out that despite a bunch of things that people are very sad to see,

54:21

salaries and so on, which by the way, if you buy a shirt on

54:24

H&M, most likely the person who made it gets less than $100 a month.

54:28

So don't feel so much bad about Shein, you might have done some worse stuff.

54:32

But Shein has some very impressive technology behind it.

54:36

They can work with almost zero stock already.

54:40

And despite the bunch of wrong things they are doing on the social level and a bunch of environmental level,

54:45

there are their pieces of things that they have done that I think should be inspiring for other brands to work with almost on demand.

54:54

They have the shopping guys shopping and then they are producing almost synchronously without overstocking.

54:59

That's really impressive how they do it with technology.

55:03

And so actually, very quickly, one of the audience questions was,

55:05

do you still think that there is room for true innovation?

55:09

through newness. He's here. Here is the place.

55:14

Fuck like a bunch of other technologies that are like a bunch of other industries that are super optimized and you are going there to create a 0.5% optimization.

55:21

No, this is the place. Like a bunch of manual labor,

55:24

a bunch of pen and paper, a bunch of foggy.

55:27

This is the place. Definitely, definitely. Beth,

55:29

I see you shaking your head. Yes, vigorously.

55:32

So, you know, do you have, is that also something that's kind of been going on in your mind as well?

55:37

Yeah, I mean, we... we are trying to replace something that was invented in the early

55:44

1800s, a sewing machine. So yes, absolutely. You're like,

55:48

yes. And sometimes it does start with something as simple as a pen and a piece of paper,

55:52

despite all the kind of new technologies,

55:56

you know, that are being put out into this world.

55:58

And so maybe to end this conversation,

56:01

which I thank you so much for sharing kind of both your trajectories and thoughts for the future.

56:08

Beth, you already mentioned it, but if I could just quickly go around for each of you,

56:13

if you could say, you know, one word that you would like to remove from maybe the vernacular of fashion industry and materials.

56:22

But then also maybe for the folks in the audience,

56:25

you know, is there a way that they can help maybe not just your company in particular,

56:30

but, you know, the fashion industry at large?

56:36

Yeah, I guess I'll repeat the word that I brought up, which

56:40

I don't want to say, I don't want to erase it. I think it's important that exists,

56:43

but just like it needs to be a little more nuanced is the word circular.

56:46

What do we mean by circular? Do we mean that this thing has an extra life and therefore it like has two loops to it?

56:52

Like does it have three lives? Is it a water bottle that has like probably four lives as PET or is it a water bottle that turns into clothing and therefore it only has one more life?

57:00

So it just is a very nuanced word and nothing is really infinite except for what.

57:06

the natural world has figured out. So

57:09

I would love some more time, someone smart to think about that word.

57:13

And then, oh gosh, there's so many things just,

57:18

I think for consumers to just be, to realize that they're always being marketed to.

57:22

And I think that this is happening. And right now there's kind of.

57:26

this green hushing that's happening.

57:28

It's no more greenwashing. Brands are being very careful about what they're putting out there.

57:32

So it, we're in a really, really weird time for,

57:36

for marketing and branding, what just everything with,

57:39

with our industry. But I would say, um,

57:42

people just dig in more and ask more questions.

57:49

Maybe I would really challenge people to know more about their clothes and to have more data about it.

57:55

I know that there is not much interest because, again,

57:57

we just care about the fashion and the price first.

58:00

And the future is brighter than it looks. And even for brands,

58:04

sometimes I talk a lot about the brands being like...

58:07

But there are some real great movements going on.

58:10

For example, H&M, which is... Lots of people point there.

58:13

fingers to them about lots of stuff that people are like,

58:16

they don't like that they do it. But the engine damage is really one of the few that is putting like putting hundreds of millions on these problems and help their supplier digitizing and become more cleaner without coal and getting electricity from the better sources.

58:29

So I would, I would suggest the audience people,

58:33

which I believe a bunch of founders and tech nerds to work in this industry,

58:37

because it is really an amazing place to create lots of impact.

58:41

And is there a word that you feel like could,

58:44

in the fashion industry, could use more nuance,

58:47

not necessarily be erased, but use more nuance as we speak about it?

58:51

Owner or self? One word. I'm asking you,

58:54

is there one word that you think? Data.

58:57

Yeah, data. Data? Okay.

59:00

Owner? On my case, I think I don't like the word replacement.

59:04

I don't like the word when these technologies are referred,

59:07

I think these technologies create a new category.

59:12

by themselves. So a new category of material that's going to be adapted by industry and also by consumers.

59:21

Just to reflect on the future,

59:23

for instance, in our case, our goal is to create a specific category of a new material.

59:28

And also how, I know we are talking about fashion today,

59:31

but how material can be used in automotive industry,

59:34

for instance, or in home goods. So how we can scale this up to create even bigger impact.

59:41

globally. Well,

59:44

thank you. And Beth, I completely agree with you.

59:46

I do feel like there has been a flattening almost of some of these words.

59:50

I feel like my word would be sustainability because I'm always like,

59:55

what do you actually mean when you're saying that?

59:58

So again, I'm just looking at the time. We ended right on 12 p.m.,

1:00:02

at least 12 p.m. my time. And so just want to once again thank the founders for joining us,

1:00:08

for sharing their insights, the audience for joining,

1:00:11

for asking your questions. And I do hope everyone took away a little something about our conversation in decarbonizing the fashion industry.

1:00:20

Thank you so much.

From The Podcast

SOSV Climate Tech Podcast

This podcast features conversations featuring world-class innovators, investors and policy experts that took place at the annual SOSV Climate Tech Summit. The event is hosted by SOSV, a deep tech VC writing its first checks via its startup programs HAX (hard tech) and IndieBio (life sciences). SOSV has over 1,000 startups in portfolio and manages over $1.5 billion.Podcast Producer: Ben JoffePodcast Summary: Written by gpt-4-turbo, edited by Ben JoffeIntro Voice: Cloned voice of Ben Joffe by ElevenLabsIntro Music: EL WailiSummit Producer: Ned DesmondSummit Curators: Ben Joffe and Ned DesmondKeywords: #deeptech #venturecapital #climatetech #healthtech #vc #robotics #lifesciences #biology #iot #internetofthings #hardware #startups #innovation #technology #frontiertech #hardtechHosted by Ausha. See ausha.co/privacy-policy for more information.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

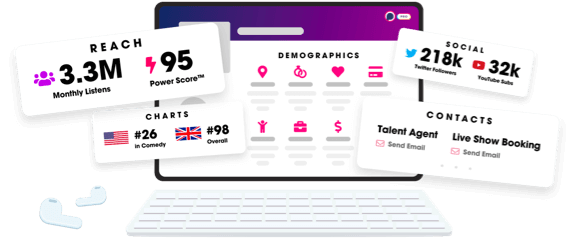

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us