Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:02

This is a branded podcast from Latitude

0:04

Studios. In

0:11

the early 2000s, Steve Cotton ran a

0:13

company serving the fast-growing data center industry

0:15

with backup battery systems. Most

0:17

battery energy storage systems, particularly for general data

0:19

centers like, think of a word, Netflix is

0:22

hosted and anything you do in

0:24

the web, we're all lead acid based. And

0:27

you would provide these big kilotons

0:30

of lead acid battery systems for

0:32

these sites. And when those

0:34

systems reach the end of their lives, the

0:36

company monetized kilotons of lead acid batteries by

0:38

sending them to recycling facilities, these industrial plants

0:41

that break down and burn the components. You

0:43

know, having the desire to understand what happens to

0:46

these batteries, I went to smelters and

0:48

they're a hellscape. It's very dangerous.

0:51

You've got lead dust all over the floor. You've

0:54

got a bunch of people wearing hot suits, literally

0:57

chucking batteries into high temperature

0:59

furnaces. And

1:01

it is not a healthy environment. It's

1:04

not a safe environment. And

1:06

there's got to be a better way. Two

1:08

decades later, the technology has shifted and

1:10

lithium ion batteries are now the dominant

1:12

form of storage. But recycling hasn't changed

1:15

a lot. Today, there are two types

1:17

of dominant battery recycling methods. One

1:19

is using high heat, similar to the process

1:21

that Steve witnessed at the lead acid facility.

1:24

And so that's also known as pyro.

1:27

And that really is high temperature

1:30

fossil fuels based. And

1:32

it doesn't recover all the materials. For example,

1:34

in lithium recycling, you burn the

1:36

lithium or you lose what lithium you

1:38

don't burn into what's called slag, which

1:40

is a solid waste stream that you

1:42

can't recover it. And

1:45

so pyro and smelting processes

1:47

have challenges. The other is

1:49

giving batteries a chemical bath in a

1:51

process known as hydrometallurgy. And

1:54

it's not really great when it comes to the

1:56

environment or worker safety. You've got

1:58

train loads of chemicals coming in. So

2:00

the economics of managing that, storing

2:02

those in massive tank farms, and

2:05

then spending tens of millions of

2:07

dollars to run a trash

2:09

dryer effectively to create what's called a

2:11

sodium sulfate waste stream is a real

2:13

challenge. Steve saw how big the

2:15

battery recycling waste problem could become. And

2:18

in 2015, after his data center power supply

2:20

company was acquired, he invested in a company

2:22

called Aqua Metal. And he became

2:24

so convinced by Aqua Metal's novel approach to

2:27

recycling, he became the CEO. What

2:29

we're doing is we're using electricity

2:32

to drive the process. And the

2:34

electricity itself comes from renewable resources,

2:37

and that can drive us with a

2:39

clean energy technology to

2:41

produce this metal supply chain with

2:44

a true opportunity to have a

2:46

net zero environmental impact. The

2:56

battery recycling industry is experiencing rapid growth,

2:58

as companies and countries like to build

3:00

secure circular supply chains for critical minerals.

3:03

In this episode, produced in partnership with

3:05

Aqua Metals, Steve Cotton sits down with

3:08

Steve and Lacey to talk about the

3:10

growing battery waste problem and the urgency

3:12

to invest in recycling techniques that don't

3:14

lock in new sources of waste. When

3:16

you produce many multiples more waste

3:18

and pollution than the valuable materials that

3:20

are recovered, is it really even recycling

3:22

is the way we look at it.

3:30

Let's talk about the scope of the problem.

3:32

We have around 100 million electric vehicle

3:35

batteries that could get retired in the

3:37

next decade. There's so much

3:39

volume coming, so much expected volume of material

3:41

that's going to need to be recycled over

3:44

the next decade as lithium-ion

3:46

batteries overtake transportation and the

3:48

grid. How do you wrap your arms around the

3:50

scope of that challenge? That's

3:53

a good rough estimate for what

3:56

is the horizon. The past 15 years,

3:58

plus the current. growing waves of

4:01

EVs that are being sold today

4:03

ultimately make their way to retirement. But

4:05

what a lot of people don't think

4:07

about is in addition, there's another major

4:10

source of lithium-ion batteries that need to

4:12

be recycled now. In

4:14

addition to all the consumer electronics, you know, what

4:16

do we do with all of our iPhone batteries

4:19

and laptop and everywhere you turn, there's

4:21

a lithium battery on a GoPro, you

4:23

name it. But the real

4:25

huge quantities that are coming today

4:27

are from these Gigafactories and

4:30

the Gigafactory battery plants themselves and

4:32

that's the form of production scrap.

4:35

And so as battery components and these

4:37

cathode, what are called cathode materials, are

4:39

cut and formed, a significant amount

4:41

of that scrap is produced and sometimes that's as

4:43

high as 10 to 15 percent of the entire

4:45

production of the plant, especially in

4:47

their earlier days as they're dialing in their

4:49

processes. So in the

4:52

near term, this is a huge primary

4:54

source of recyclable materials for companies like

4:56

Aqua Metals. And you know,

4:58

from now until the end of the decade,

5:01

we think there's an estimated 10

5:04

million tons or so of combined

5:06

scrap material and end-of-life batteries that

5:09

are really going to be ready to be recycled. And

5:12

another data point that's interesting is

5:14

the US alone is

5:16

going to be increasing our Gigafactory

5:19

output by 200x just this decade.

5:21

And that's what started

5:24

as Tesla's Gigafactory 1 that's right

5:26

here by Aqua Metals in Tahoe,

5:29

Reno, Nevada, with

5:31

its original Gigafactory. And the

5:33

US is really rapidly standing

5:35

up Gigafactories all over the

5:37

country to reach that

5:39

200x production levels, which is just

5:41

a staggering stand-up of an entire

5:44

battery production industry right here in

5:46

the US. And

5:48

also the global market for lithium-ion

5:50

batteries is really accelerating at a

5:52

meteoric pace with demand

5:55

for these new electric vehicles really leading

5:57

the way. the

6:00

first time ever that in the US over

6:02

1 million EVs were sold and There's

6:05

already over a hundred models to

6:07

be offered in the coming year. So there's a

6:10

lot of momentum

6:12

in that space and It's

6:14

driving a lot of the battery gigafactory

6:16

builds and of course the production scrap

6:19

and then ultimately the end-of-life cells and

6:21

so along with that the availability of

6:23

end-of-life batteries and Manufacturing

6:25

scrap materials is quickly rising

6:28

and if you look at the global lithium battery

6:30

recycling market It's already

6:33

today roughly a five billion

6:35

dollar industry and we expect

6:37

it to grow by about five Fold just in

6:39

the coming few years to the end of the

6:41

decade to nearly 25 billion dollars

6:43

when you think about the material inside

6:47

the battery What

6:49

are the most valuable materials and

6:51

and where are those materials going

6:54

after they've been extracted and

6:56

reused? So the

6:58

materials that come out of lithium-ion batteries

7:01

are actually quite valuable And the

7:03

primary list of that is the

7:05

lithium and the nickel and the

7:07

cobalt And

7:09

there's also some copper and some

7:12

manganese that can be

7:14

recaptured from our recycling

7:16

process But if you

7:18

look at the three highest value minerals, which is

7:20

the lithium and the nickel and the cobalt That's

7:23

really what we're after when we're recovering

7:26

from the economic aspect of The

7:29

lithium batteries I'd say that the smaller amounts

7:31

of copper and manganese Is

7:34

reuse oriented so it's a multi

7:36

mineral recovery So it's very complex

7:38

to be able to get those

7:41

minerals and recapture them and get

7:43

them Inspect to go back into

7:45

new batteries with battery manufacturers Now

7:48

as people look to the future of battery

7:50

recycling, they often Look

7:53

at the lead acid battery recycling

7:56

industry where the vast majority of

7:58

materials in battery are reused.

8:01

I think 95% of materials inside

8:03

lead acid batteries are reused. But

8:06

there's definitely a darker side to

8:08

that recycling story. What

8:11

is that? Yeah, so the positive

8:13

side of that is that the

8:15

lead recycling industry has done an

8:17

incredible job of building the infrastructure

8:19

to recycle nearly a hundred percent

8:21

of spent batteries. So

8:24

if you go and put in a new

8:26

car battery, like a new lead acid battery

8:28

or a new battery in a data center,

8:30

as an example I was referring to earlier,

8:33

the amount of metal in that battery that

8:35

came from a recycled source is about 80

8:37

to 90 percent. So those

8:39

new batteries are mostly old batteries

8:42

reborn as new batteries. And

8:44

if you contrast that today to a

8:46

new lithium battery that you get, regardless

8:49

of the application, whether it's an EV or

8:52

a piece of consumer electronics, etc., that

8:54

has under 1% of

8:57

the recycled lithium nickel or cobalt

8:59

in that new battery. It all

9:01

comes from mining sources today. And

9:03

that's going to change over time. And

9:06

as the lithium industry grows

9:08

and stabilizes and

9:11

the hyper growth curve stabilizes,

9:14

we make this transition. More and

9:16

more recycling infrastructure gets built. We

9:18

get closer and closer and migrate

9:21

from that less than 1% to 80

9:23

to 90 percent, just like what lead

9:25

has shown us. And it's really only

9:28

a couple decades of recycling, so it'll

9:30

happen fairly quickly. But really

9:32

the environmental and worker safety

9:34

impacts of lead recycling has

9:36

been a challenge through smelting

9:39

and has really put in incredible stress and

9:41

communities. And that's in the form

9:43

of massive pollution that goes into

9:45

the world in the

9:47

form of things like greenhouse gas and

9:49

CO2, but also the particulate matter material

9:52

and lead dust that could spread throughout

9:54

a community. Workers get

9:56

lead in their blood and

9:58

have injuries and deaths. And

10:01

we want to make sure that this

10:03

type of infrastructure is what doesn't get

10:05

built as we go from this 1%

10:08

to the 90% of lithium batteries

10:10

coming from recycled infrastructure in the

10:13

coming years. And I

10:15

think that we have a unique opportunity as an

10:18

industry and really the world to

10:20

build this massive lithium

10:22

battery recycling infrastructure right the first

10:25

time. So we're not talking about

10:27

going back and upgrading smelters

10:30

or standard hydro chemically intensive

10:32

processes with all the risks to

10:35

workers and waste streams. And

10:37

if you do that right the first time,

10:39

you've got the answer that we can be

10:42

really proud of in the future and really

10:44

make this transition a clean transition. So

10:46

that brings us to the aqua

10:49

metals recycling process. It replaces

10:52

chemical baths and high heat

10:55

with electricity to recover lithium

10:57

hydroxide, nickel cobalt, manganese dioxide.

10:59

The process has its roots

11:01

in the lead acid battery

11:03

industry. How does it

11:06

work? Yeah, so aqua refining is

11:08

what we call our suite of

11:10

technologies and it's all

11:12

our IP and our patent and patent

11:14

pending process. And what it does is

11:16

it utilizes a clean

11:19

electricity based which

11:21

could be renewable electricity closed

11:24

loop process. And that closed

11:26

loop process within the recycling

11:28

process produces high purity

11:31

metals from shredded lithium

11:33

ion batteries that we get

11:35

from what are called black

11:37

mass providers. And we can

11:40

deliver those raw materials right back

11:42

into the manufacturing supply chain with

11:44

aqua refining without the

11:46

emissions and really toxic

11:48

byproducts. And it really stands

11:51

out because we're recycling the

11:53

chemicals and regenerating the chemicals

11:56

through our innovative and unique processes

11:58

by using electricity. And we

12:00

use those chemicals over and over and

12:02

over again in that closed loop versus

12:05

a one-time use. And we don't

12:08

create these huge waste streams that

12:10

I was talking about earlier, like sodium

12:13

sulfate as an example, which can sometimes

12:15

exceed the amount of recycled materials. We

12:17

create none of that because we're reassembling

12:19

those molecules within our process over and

12:21

over again. And then ultimately

12:23

what does come out of the process

12:25

is things that we want to reuse

12:28

and put back into the battery supply chain

12:30

like lithium and cobalt and nickel

12:32

and copper and manganese. And

12:35

the other aspect of aqua refining

12:37

that's super critical and super important

12:40

is the working environment really only

12:42

requires safety goggles and a

12:44

lab coat. And you're working

12:46

in a room temperature area with

12:48

super clean facilities where

12:50

the temperatures really only reach about

12:53

hot tub temperatures in the isolated

12:55

tanks with pipes and pumps

12:57

and keeping everything away from the workers. And

12:59

that ultimately serves

13:01

our mission and goal of

13:04

creating jobs that members of

13:06

our own families and friends and

13:09

the general community actually want because people

13:11

don't want to go work in

13:14

a very difficult chemical or heat

13:16

intensive environment. And we

13:18

are, as a part of our mission, are

13:21

really trying to create desirable 21st century jobs

13:24

of the future. Yeah, so you've

13:26

got this pilot plant operating in Nevada right

13:29

now and what's the scale of

13:31

that plant? How much material are you processing?

13:33

And then what is the commercial facility that

13:36

you're planning when the fully operational look like?

13:38

Yeah, so we took a unique approach, I

13:40

think, as compared to a lot of other

13:42

players that are trying to move perhaps too

13:45

quickly in this industry that's getting

13:47

stood up. And we decided

13:49

at the early on days of our

13:52

lithium aqua refining program to go through

13:54

lab scale, then bench scale, and then

13:56

pilot scale, and then commercial demonstration plant,

13:58

and then mass. of commercial plant.

14:01

So we've already gone through the lab

14:05

and the bench testing and we built

14:07

a pilot plant and for the last

14:10

year have been operating our pilot plant

14:12

successfully and demonstrating our

14:14

first of kind technology and

14:16

producing all these critical minerals from that pilot plant, which

14:18

this quarter is going to go to 24 hours a

14:21

day by seven day

14:23

a week operations as we continue to

14:25

build out our commercial plant I'll talk

14:28

about later. So

14:30

that pilot facility today generates between 75 and

14:32

100 tons of volume of material per year.

14:36

So it's not really an economic

14:38

purpose. It's a validation of technology

14:40

and getting the critical minerals in

14:43

the hands of battery manufacturers and

14:45

big auto and EV manufacturers and

14:48

informed the scale up of our

14:50

technology. We're currently producing those high

14:52

purity minerals and products in

14:55

the form of things like lithium in

14:57

the form of lithium hydroxide, which is a

14:59

white substance and

15:02

also lithium carbonate. We

15:04

can make both of those forms

15:06

of lithium. And as

15:08

an example, the lithium that was

15:10

produced from our pilot plant was

15:12

recently used by our partners right

15:15

down the road here in Tahoe

15:17

Reno, Nevada, called Dragonfly Energy. And

15:19

Dragonfly Energy successfully manufactured

15:22

and cycled and tested lithium

15:25

ion battery phosphate next

15:27

generation cells and

15:29

proved that our lithium from a

15:31

recycled source went into that process.

15:33

That's a huge thing, because that

15:35

might be the first lithium

15:38

cells built in the world that

15:40

were made from sustainably recycled lithium

15:43

at 100% level. So we're now building

15:46

out our workforce and expanding our team

15:49

and getting that pilot plant operating 24

15:52

by 7 in Q1 of this year, 2024, as we get our

15:54

commercial demonstration facility. the

16:00

Sierra Arc up and running, which will start

16:02

to come online beginning in late Q2 of

16:05

2024. This is

16:07

a space that has garnered a

16:09

lot of investor interest, a lot

16:11

of potential policy support.

16:14

More and more eyes are now on

16:17

the importance of lithium battery recycling, but

16:19

it's still a very immature

16:22

industry, especially compared to something like

16:24

the lead-acid battery recycling industry. How

16:28

do you define the current supply chain

16:30

from how you

16:32

source materials to selling the

16:34

recycled materials? How immature

16:36

is it and how could it be refined?

16:39

Yeah, so the current supply

16:41

chain is today in

16:43

terms of commercial scale really smelters and

16:45

these hydro processes. The hydro processes that

16:47

are up and running at any scale

16:50

are happening in China. The

16:52

smelting is happening mostly in Europe

16:54

and a lot here in the

16:56

US as well as it

16:59

gets started. But now that's really

17:01

less than 1%, like I

17:03

was mentioning earlier, of batteries that are

17:05

getting back into the supply chain through

17:07

those recycled processes. So therein lies the

17:09

opportunity to build this new

17:12

infrastructure. And aqua

17:14

refining is what we

17:16

believe is a technology suite that will

17:18

allow us to build that infrastructure so

17:20

it's clean, safe, and protects

17:22

the workers and all those great things.

17:25

And so we've structured our business model

17:27

to help this industry really

17:29

stand up by creating an

17:32

intrinsic set of our own IP and

17:34

our own patents and building our own

17:37

facility, which today our first commercial facility

17:39

we call the Sierra Arc because

17:41

it's in the Tahoe-Reno area so it's right

17:44

by the Sierras. And the Arc stands for

17:46

Aqua Refining Recycling Center. And

17:49

that Sierra Arc will prove the technology

17:51

at scale. So then

17:53

with our IP we can joint

17:55

venture, license, and partner with other

17:57

players in the world to... develop

18:00

new recycling centers utilizing the superior

18:02

suite of technologies. We've already evidenced

18:05

that with a first licensee partner

18:07

of ours that's in Korea called

18:09

Yulho materials that made an investment

18:12

in AquaMuddles last year is

18:14

turning on right now a pretty

18:17

large lithium ion battery crushing and

18:19

shredding facility to create that black

18:21

mass that is the input into

18:23

our process. And they'll be building

18:26

basically a twin of our Sierra

18:28

arc in South Korea just

18:30

south of Seoul in the

18:32

coming years. And that will be the first

18:34

example of what we believe will be many

18:37

of partners that we can work with

18:39

to propagate what we believe is the

18:41

proper technology to do this recycling. So

18:43

we started this conversation by talking about

18:45

how important it is to lock

18:49

in cleaner infrastructure now,

18:51

because if we lock in more polluting methods,

18:53

it's going to be very hard to

18:56

displace as this industry scales and battery

18:59

waste mounts. So I want

19:01

to end this conversation with two scenarios.

19:03

One is just what

19:05

you think that the battery recycling industry looks like

19:07

or the pollution problem looks like if we don't

19:09

get this right. If if

19:12

we focus on solutions that you say are

19:14

problematic. And what is a well

19:16

managed clean circular battery

19:19

recycling industry look like? So walk me

19:21

through those two potential scenarios if we

19:23

are sitting at this really critical moment.

19:27

Yeah, there's really two alternate

19:29

future scenarios here. One

19:31

is that we continue to smelt and

19:34

run really chemical intensive and

19:37

waste producing and greenhouse

19:40

gas producing waste streams.

19:43

And that will create what

19:46

is already one of the top 10 most

19:48

pollutive industries in the world smelting times 10.

19:51

And we will not have

19:54

solved any problems in this

19:56

grand electrification transition from fossil fuels

19:58

to a world of. the battery age

20:01

and renewable energy storage and electric

20:03

vehicles that are powered by renewable

20:05

energy sources in the future. If

20:09

we recycle in the back office

20:11

all that stuff with a dirty

20:13

process, we won't have solved

20:15

these problems at all and we're gonna be

20:17

apologizing to our kids and grandkids that we

20:19

had a great idea but we didn't execute

20:22

it properly. The alternative universe is that we

20:24

find the right way to dig up these

20:26

minerals once from

20:28

the mining processes and reuse them

20:30

over and over and over infinitely as

20:33

we build and grow our capacities

20:36

of battery energy storage in the

20:38

form of massive quantities of EV

20:40

fleets and battery energy storage systems.

20:43

And by reusing those minerals and

20:45

doing that in a clean way

20:47

that doesn't impact the environment but

20:50

is very favorable to the environment is

20:52

gonna be that alternative universe that

20:55

we're certainly pursuing. And

20:57

that is something that we can brag

20:59

about to our kids and

21:01

grandkids that this great transition was

21:04

done by this generation and

21:06

really truly made the difference

21:08

for the climate and worker

21:10

environment and the real

21:13

battery age and utopian view of

21:15

society being powered by renewable energy.

21:17

Steve Gotton, President and CEO of

21:19

Aqua Metals. Thank you so much.

21:22

Thank you. Aqua

21:24

Metals is pioneering cleaner

21:26

and safer battery metals recycling through

21:28

innovation. The company is

21:30

building the first sustainable battery recycling

21:32

operation in North America in

21:35

Tahoe, Reno, expanding breakthrough tech that

21:38

can deliver high value raw materials while

21:41

reducing emissions and toxic byproducts. If you

21:43

wanna learn more about the sustainable closed-loop

21:45

metal recycling process from Aqua Metals, go

21:48

to aquametals.com. Thank

21:53

you.

From The Podcast

The Carbon Copy

A narrative news show about the trends shifting our carbon-based economy. Each week, host Stephen Lacey digs into the business and technology stories that explain the rise of clean energy, the challenge to fossil fuels, and how the energy system is transforming in dramatic ways. Produced by Latitude Media.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

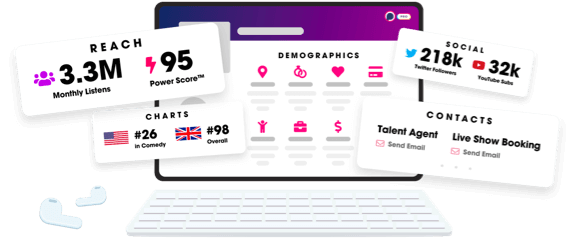

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us