Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:00

Solar is the fastest-growing electricity-generating technology in

0:02

history. It took coal 32 years to

0:05

grow from 100 terawatt hours of generation

0:07

to 1,000 terawatt hours. It

0:10

took fossil gas 28 years, wind was a

0:12

dozen years, and it took solar 8 years

0:14

to hit that milestone. We

0:16

will surpass a terawatt of PV manufacturing

0:19

capacity this year. And that

0:21

scale was the result of squeezing cost reductions

0:23

out of every step of production. But

0:25

there's one critical piece that hasn't changed much

0:27

— frames — which now make up one

0:30

quarter of the cost of a module.

0:32

The one component of a PV module

0:34

that had not seen dramatic reductions in

0:36

cost or performance. We said there's got

0:38

to be a way to do it.

0:40

That was it. Greg

0:44

Patterson is the CEO of Origami Solar. He's

0:46

a former VP at Hewlett-Packard, who got into

0:48

the solar business in 2007. He

0:51

ran an inverter maker and a

0:53

distributed battery developer, both of which

0:55

had successful acquisitions. And four

0:57

years ago, he teamed up with a

1:00

group of fellow solar veterans to focus

1:02

on replacing aluminum with recycled steel for

1:04

frames. We started before COVID. We started

1:07

before Ukraine, before

1:09

any of the geopolitical tensions had gotten

1:11

as high as they were now. And

1:14

as those real-world

1:16

events played out, it

1:19

became clear that aluminum frames

1:21

is an Achilles heel for solar.

1:23

In the years after a pandemic

1:25

and a war pushed aluminum prices

1:27

to historic highs, supply chains for

1:29

all types of imported materials and

1:32

equipment were upended. And America's trade

1:34

tensions with China — a country

1:36

that happens to control nearly 60

1:38

percent of aluminum supply — also

1:40

worsened. The evolution of

1:42

the world around us has

1:44

created such a

1:46

significant risk to

1:49

imported aluminum frames. We saw

1:51

a confluence of these supply

1:53

shocks for solar. I mean,

1:55

we had everything from polysilicon

1:57

shortages, of course, the issues

1:59

with solar. international trade and

2:01

shipping meant that those

2:03

bottlenecks increased shipping costs for solar modules

2:05

as well. MJ Shao is the VP

2:08

of supply chain and manufacturing at the

2:10

American Clean Power Association. That's a trade

2:12

group pushing for policies that support domestic

2:15

clean energy. He worked at a major

2:17

solar manufacturer during that rough time and

2:19

he experienced the mess firsthand. And

2:22

so when there is that

2:24

over concentration of supply,

2:26

then that means when there

2:28

are these policy, trade,

2:31

even just logistical whiplashes

2:33

that are happening, the

2:36

industry becomes far more vulnerable.

2:38

And given the dominant supply

2:40

position globally that China has

2:43

on aluminum, and given

2:45

the rapid growth that solar is

2:47

being tasked to fulfill, we

2:50

realize that this is increasing

2:53

the risk of staying with the

2:55

incumbent. It may sound simple to

2:57

just swap out a different metal for frames. It

2:59

is not. It takes years of designing

3:01

and testing and then convincing manufacturers and

3:04

developers to make the switch. But

3:06

a combination of domestic content rules, new

3:08

tariffs on Chinese metals, reliability problems with

3:11

bigger modules, and a focus on embodied

3:13

emissions of clean energy products are setting

3:15

the stage for a shift in how

3:17

those frames are built. And as it's

3:19

played out, it's like the perfect solution

3:21

at the perfect time. I'm

3:26

Stephen Lacy, and this week we've got

3:28

a conversation I held with Greg Patterson

3:30

of Origami Solar and MJ Shao of

3:32

the American Clean Power Association. It was

3:35

recorded live as part of our Frontier

3:37

Forum series. And we asked, what would

3:39

it take to replace foreign-sourced aluminum with

3:41

US-made recycled steel? And why does it

3:43

matter? This conversation isn't

3:45

just about frames. It's a story

3:47

about geopolitics, trade, the complexities of

3:49

manufacturing, and the urgency of improving

3:52

the reliability of solar. So

4:00

did you start by

4:03

evaluating recycled steel first? How

4:06

did you like tackle the problem initially? Steel

4:08

is a better metal. The thing

4:11

that we had to solve first

4:13

and foremost was corrosion concerns, steel

4:17

rusts, perceptions, aluminum doesn't.

4:20

And aluminum is a really good corrosion solution,

4:23

especially anodized aluminum. But

4:25

we realized that if you could solve corrosion,

4:28

which I'll walk through in detail how we

4:30

did that, as well as

4:32

the weight, because steel is much,

4:35

much denser than aluminum. And

4:37

that's where the design challenge was,

4:39

is how do you really minimize

4:42

to a point of immateriality, the weight

4:45

gain of a steel frame versus an

4:47

aluminum frame? And so, and

4:50

the increasing focus on decarbonizing

4:52

solar, it was

4:54

just a natural with the

4:56

opportunity of the robust regional and

4:59

special domestic recycled steel industry. Because

5:01

recycled steel is the vast majority

5:03

of the steel used in the

5:05

US today and Europe and most

5:07

other regions. And so it

5:09

was a wonderful blend of the

5:11

opportunities and steel's inherent

5:14

fatigue resistance, higher strength.

5:18

It's truly just a better metal than

5:20

aluminum for a steel frame application. So

5:23

we're gonna dig into each of those

5:26

things a little bit deeper throughout

5:28

the conversation. MJ, I wanna roll

5:30

over to you and ask about some of

5:32

these macro trends that we just

5:34

set up. So ACP's mission is to support

5:37

the build out of a

5:39

domestic clean energy industry. You're

5:42

a supply chain expert, worked in

5:44

the industry. You have also

5:46

been an analyst in the industry. What is your take

5:48

on some of the risks that

5:51

I outlined and that Greg outlined?

5:54

You've outlined a lot of the categories

5:56

of risk and I'd also add that

5:59

this is... is an opportunity as

6:01

well for the industry. But as

6:04

far as the risk is concerned, any

6:06

procurement lead out there will tell

6:09

you that a diversity of supply

6:11

options is necessary to ensure that

6:13

you have a resilient, secure supply.

6:17

And the unfortunate reality of today

6:19

for the solar supply chain is

6:21

that there are parts, components of

6:24

the core solar supply

6:26

chain that are heavily dominated

6:28

by manufacturing in China, and

6:30

that makes the industry vulnerable

6:33

to supply shocks. And

6:35

this is a lived experience for the industry.

6:37

And so, I think there's

6:39

an opportunity here too, not

6:42

only just to de-risk that, but

6:44

also, we are in

6:47

the beginnings of a historic

6:49

expansion of US

6:51

clean energy manufacturing capacity. Just

6:55

for solar alone, we've seen 85 new or

6:58

expanded solar manufacturing facilities being announced

7:01

in the US. That's over

7:03

28,000 jobs. That's

7:07

tens of billions of dollars of

7:09

investment in local communities. And that

7:11

is also part of

7:14

the solar industry story

7:16

that I think is really

7:18

exciting too. This is no longer about

7:21

necessarily just buying foreign materials,

7:23

but it's also having solar

7:26

reinvest in the community, not just

7:29

from the perspective of having low

7:32

cost, reliable, clean

7:35

electricity, but also putting

7:37

long-term manufacturing jobs in

7:39

these communities as well. Greg,

7:42

tell me more about what the

7:44

most, the highest value propositions are.

7:47

Tell me about cost comparisons. How

7:50

much are you factoring in like

7:52

emissions and the move

7:54

to factor in embodied emissions and

7:56

the development and purchase of solar

7:59

products? What are the most significant

8:01

value propositions that potential customers are

8:03

interested in? Steel

8:06

frames is a very

8:08

strategic way to de-risk the supply

8:10

chain. It's not the whole supply

8:12

chain for a module or

8:14

for a project, but it is

8:16

material being number two or three on the

8:19

old bomb. And so I

8:22

think if you look at the value

8:24

proposition, it's stacked, but I'd say de-risking

8:26

the supply chain is first and foremost.

8:29

Because when you have

8:31

the existential threat of interruptions

8:34

or arbitrary price increases because

8:36

of tariffs or

8:39

political decisions made on either side of the

8:41

Pacific, that's really

8:43

hard to manage. It's really hard to

8:45

hedge. So that's it. And

8:48

you get a great combo given

8:50

the domestic content that the IRA

8:52

provides in terms of the tax

8:54

credit, you get a material impact

8:57

on increasing your domestic content as

8:59

you de-risk the

9:02

supply chain from Asia. The

9:05

next one that's really starting to play out,

9:07

and this has been coming, I'd say the

9:09

last six to nine months, there's an increasing

9:11

focus on module

9:13

fragility. The

9:17

reality is the size of modules

9:19

have increased over 40%. At

9:23

the same time, there's been cost down

9:25

efforts on both glass and frames to

9:27

reduce the material and thus

9:30

the structural capabilities. And

9:32

so we have this perfect storm

9:36

of cost reduction, the

9:38

core structural elements. At

9:41

the same time, we're seeing more

9:43

and more weather, extreme weather events,

9:45

be it wind, snow

9:48

or hail that is

9:50

requiring a higher performance structural

9:52

support for modules. And

9:55

so with steel frames, we've already

9:57

demonstrated third party tested and we're

10:00

making lots of public

10:02

statements and visibility and talking about it

10:04

all the time. The steel

10:06

frames are higher performance because it's a better

10:08

metal and we've designed a really, really good

10:10

steel frame. And so

10:13

that performance improvement

10:15

to deal with the reality

10:17

of our future solar market

10:19

and environment is key. And

10:22

then finally, it is the decarbonization. When

10:24

we got into it, we didn't realize how

10:27

big it was. We knew it would be material, but

10:29

we never realized it would be a 90% reduction over

10:33

imported aluminum frames. And it's

10:35

not just the transit from Asia to

10:37

the US or Europe. It

10:39

truly is just that aluminum

10:41

is an insanely dirty metal.

10:45

And so the ability to do

10:47

that and the growing focus on

10:49

decarbonizing solar has to lead that.

10:52

And so it truly has been

10:54

an incredible evolution and

10:56

expansion of the value proposition

10:59

over the last four years.

11:01

Especially the first two points, de-risking

11:04

and technical performance, those

11:06

are intertwined as well.

11:09

For example, I was speaking with

11:11

someone earlier this week who had

11:13

dozens of megawatts of modules that

11:15

were broken through tennis

11:17

ball size tail. And

11:21

that in the middle of the current environment

11:23

where there's uncertainty with

11:25

tariffs, there's kind of

11:28

a moving policy with what's

11:30

happening again, non-trade. That

11:33

means that replacing those panels isn't

11:36

a simple exercise of just calling up

11:38

the same manufacturer anymore and there's redesign

11:40

work. So there is

11:43

this interconnectiveness between having

11:46

that resilience of the actual technical module

11:48

as well as of the supply chain

11:50

as well. As we've

11:52

been presenting at conferences and shows

11:54

and to customers and

11:57

just interested parties.

12:01

We're getting anecdotal feedback

12:03

on wind and

12:05

snow damage that is material.

12:08

And so we're seeing all

12:11

the big players, DNV, CEA,

12:14

starting to elevate this concern. And

12:17

so I believe this is an

12:20

emerging and material impact.

12:23

And the cost down dogma is,

12:27

we got to do it selectively. Cost

12:30

is always going to be important, but we got

12:32

to do it selectively. And we now have virtually

12:36

insufficient margin to deal with

12:38

a much more turbulent climate

12:41

future. How did you land

12:43

on this 90% reduction

12:46

in GHD, in body GHD

12:49

emissions in production of these

12:51

frames compared with aluminum module

12:54

frames? This

12:56

was a report that you put together with

12:59

Boundless Impact Partners.

13:04

So tell me about that analysis and the

13:06

actual comparison and how you came to those

13:08

numbers. Yeah, we did. We realized

13:10

that just like with our

13:12

testing results, we want to use third

13:15

parties, very, very credible third parties. And

13:18

Boundless Impact is a very focused

13:21

engineering consulting firm that does life

13:23

cycle analytics. And

13:25

so we basically just told them

13:27

the characteristics of

13:29

our steel frame, and then they

13:31

researched aluminum frames. And

13:34

they developed this. And that

13:36

90% reduction per average

13:38

size module is

13:40

based on their analysis. And

13:43

we've updated it with actually our definitive

13:45

supply chain, and it got a little

13:47

bit better. But it

13:49

really is a rigorous analysis. And

13:55

that 90% reduction, which is a really

13:57

big relative number, translates also to

13:59

a about a 90 kilogram

14:02

carbon footprint reduction per module.

14:06

And if you scale that to

14:08

gigawatt scale, I think it's like 180,000 metric tons of

14:14

carbon avoided per

14:16

gigawatt. And so that is

14:19

absolute materiality if you

14:21

look at it. And so we're

14:23

also working very closely with the

14:25

Ultra Low Carbon Solar Alliance, we're

14:27

members, and they have

14:30

been pushing the EPEAT EcoLabel. And

14:32

we are literally geared up

14:35

and with literally third-party validated

14:38

reductions. What

14:40

we're able to do is provide to

14:42

our customers that buy the module manufacturers

14:45

a absolute data-driven reduction that

14:47

they could go and try

14:49

to achieve the EPEAT criteria

14:52

that I think is gonna become increasingly more

14:55

important going forward. Cause we're seeing a lot

14:57

of attention and focus on

14:59

Ultra Low Carbon and the

15:01

EPEAT standard. MJ, why do embodied

15:03

emissions matter? And of course they matter for

15:06

the planet. Like we should all be thinking

15:08

about the emissions

15:10

from producing products, but are

15:12

companies actually demanding low embodied

15:15

emissions products along the supply chain?

15:17

And where does the policy component

15:19

come in? Like if

15:22

I think about Europe's carbon border adjustment tax,

15:25

why could that potentially influence

15:28

investments in lower embodied emissions

15:30

products? Solar and clean

15:32

energy should really lead on this, right?

15:34

It doesn't make sense if we're, it

15:37

doesn't make sense for a fitness instructor to be

15:40

like, well, I teach other people how to be

15:42

healthy, but I do and eat

15:44

whatever I want, right? So as

15:46

the clean energy industry, we should also be leading on

15:49

this front. But

15:52

beyond that, I mean, that's not convincing

15:54

enough. There are reasons

15:56

why this is becoming important. First of

15:58

all, of the end

16:01

users are starting to look more and

16:03

more into scope three emissions. And as

16:05

they set their carbon reduction

16:07

targets, their net zero carbon

16:09

targets, the embodied carbon

16:12

in their supply chain matters

16:15

more and more and more. So if

16:18

that goes for folks that

16:21

are, whether they're buying the

16:23

modules themselves or they're buying

16:25

the electricity generated from a

16:28

solar power plant, the carbon

16:30

intensity of actually producing that

16:33

solar energy also matters.

16:36

I think secondly that you're seeing it

16:39

as a way for folks either

16:41

to address their trade or carbon

16:43

priorities as well as looking at

16:46

the carbon intensity of supply chains.

16:48

So for example, right now, the

16:51

EU has a carbon border adjustment

16:53

mechanism in place. So for key

16:56

industries, they are actually looking at

16:58

the embedded

17:00

carbon of the importer product

17:02

and if the origin

17:05

or the source of that product doesn't have

17:07

a price or some sort of inclusion on

17:11

carbon in that

17:13

whole market, then they're going to put a tariff

17:15

on it. It essentially is

17:17

a trade mechanism to enforce

17:19

and ensure that the product

17:21

coming into the EU is

17:24

at the same, has the same

17:27

climate standards that they put on their

17:29

own industries. And so this is

17:31

going to be important for anybody that obviously

17:33

wants to trade with the EU

17:35

in those sectors and it's being discussed in

17:38

other places, the US included. So

17:40

that brings us to a bigger policy

17:42

conversation that I suspect a lot of

17:45

people are going to be very interested

17:47

in. And as we

17:49

said, de-risking the supply

17:51

chain is one of the biggest value

17:54

propositions here. And

17:56

I want to reflect on the current

17:58

environment policy. as a

18:00

backdrop to this. So the Biden administration

18:03

recently unveiled new tariffs

18:05

that will cover about $18 billion worth of

18:08

imports under section 301 of the 1974 trade act, Chinese EVs, EV batteries,

18:13

solar modules, steel, and aluminum.

18:16

MJ, give us an overview. What are these

18:19

tariffs designed to do and how

18:21

do we separate them from the ongoing

18:23

ADCVD case on finished

18:25

aluminum products? As

18:28

you say, there's an alphabet soup of tariffs

18:30

here. So help us to sort of understand

18:33

the policy backdrop. It's all my

18:35

line, Steven. But

18:37

yes, there is- I gave you credit for it

18:39

though. Right. There's also the classroom of 201, 301,

18:42

all sorts of numbers of tariffs as well. But

18:48

starting with the section 301 tariffs,

18:50

so just as quick history, these

18:53

were originally implemented under

18:56

the Trump administration, really

18:58

targeting products imported from

19:00

China. They were

19:03

maintained by the Biden administration when

19:06

Biden was elected and these

19:08

were recently refreshed. And

19:11

there are some changes made to what

19:14

was included or raised or added

19:16

to those tariffs as well. And

19:19

it just highlights that

19:22

while there are some of some

19:24

detailed and nuanced differences in policy

19:27

and focus, it's very clear that

19:30

competitiveness with China is a bipartisan

19:32

issue in this country. It is

19:34

going to remain a priority

19:37

for either administration in

19:40

the new year after the election.

19:42

And really the challenge is

19:45

clearly broader than just setting up

19:47

some domestic manufacturing of goods. It

19:49

really is how do we do

19:52

risk and transition the dependence on

19:55

China for many of our supply chains, not

19:57

just solar energy. So

20:00

I think that when you talk about

20:02

focus is really the focus there. In

20:05

terms of its impact on clean energy itself,

20:07

not to toot our own horn here, but

20:12

I think we at ACP

20:15

have been pretty proud of how we

20:17

helped to shape some of the 301

20:19

tariffs that apply to clean energy. For

20:22

example, with our counterparts at SIA, we

20:25

worked really hard with our battery manufacturers

20:27

looking at cells versus module

20:29

manufacturing in this company and

20:32

saw that there was a lag in cells

20:34

and was able to really support a

20:36

case for this delay in non-EV

20:39

cell tariffs going up in

20:42

2026 instead of immediately for EV

20:44

battery cells. And I think

20:47

another thing that's in there that wasn't

20:50

broadcast as much, but I think is really

20:52

beneficial and more relevant to this conversation is

20:54

that there are these exemptions

20:57

for solar

20:59

manufacturing equipment, and that

21:01

is going to directly help a lot of

21:03

the domestic solar manufacturers that

21:06

are buying equipment right now, bringing it into

21:08

this country, and now

21:10

don't have to pay a 25% tariff, which

21:14

reduces the CAPEX and, again,

21:16

increases the competitiveness,

21:18

lowers the cost of domestic

21:20

manufacturing. So I think there

21:24

are good things that are embedded for

21:26

clean energy in these tariffs. I think

21:28

when we look broadly at tariffs in

21:32

general, though, the challenge

21:34

has always been that there's a

21:37

great deal of uncertainty that comes

21:39

with these tariffs. They're not surgical.

21:41

A lot of times the rules

21:44

and regulations don't necessarily allow them

21:46

to provide a lot of visibility

21:48

ahead of time. And

21:50

I think that is something that, for

21:52

example, the Biden administration has been helpful

21:56

in thinking about how do you create

21:58

some transition periods for these

22:00

tariffs. industry. The solar industry, I

22:02

think, is remarkably resilient and able

22:06

to change

22:08

supply chains, but it needs

22:10

the time. And so we've seen that with, for

22:12

example, the two-year tariff moratorium

22:14

on Southeast Asia imports when

22:16

the OXIN investigation was first

22:18

starting up two years ago.

22:20

We saw that with,

22:23

again, this 301, one and a half

22:25

year delay for the sell

22:28

tariffs for batteries, even the Section 201

22:31

tariff. Although there's

22:33

a re-implemented tariffs

22:35

on bifacial module imports,

22:38

there's this 90-day safe

22:41

harbor for contracted goods. So

22:43

again, the signal is clearly to

22:46

de-risk from China to, in

22:48

many cases, help support domestic

22:51

manufacturing, but also allowing the

22:53

buyers, the downstream community, that

22:55

time to transition to for these

22:58

new policies as well. All right, so distill this

23:00

down for me a little bit more. There's

23:03

been this long running debate

23:05

in the industry over whether

23:07

these penalties will hurt

23:09

the domestic energy transition, raise

23:12

equipment costs, create further uncertainty,

23:15

or actually build the

23:17

real domestic industry. How's the

23:19

market reacting right now? What are

23:21

the really key pieces of fear,

23:23

uncertainty, and doubt? Yeah,

23:25

I mean, I think there's a

23:28

spectrum of reactions, right? In general,

23:30

it's the uncertainty that kills. So

23:32

first, the folks that

23:35

are more hedged, that are

23:37

more diversified, they may not

23:40

be feeling the pain as much as folks

23:43

that are over-indexed on

23:45

any particular part of the supply

23:47

chain, right? And that's,

23:49

again, that's always been the challenge is that there

23:53

is the challenge, if there

23:55

isn't a diversity of a supply chain, that these

23:58

whiplashes and policies. can have

24:00

a much greater impact on the

24:03

overall market, starts to feel more

24:05

existential when there is diversity, the

24:08

industry can be more resilient.

24:11

To chime in there, I mean, Origami

24:14

doesn't need the tariffs to build a business

24:16

case. MJ has forgotten more

24:18

than I could tell you about tariffs

24:21

and everything that is dynamically going on. But

24:25

what I will tell you in the last two

24:27

or three months is the aluminum AD CVD case

24:29

and the recent Biden administration,

24:31

Terrace on Steel and aluminum from

24:34

China. My

24:37

sense is talking to everybody and our

24:39

customers are the module makers in the

24:41

US, Europe and actually

24:43

India. It was the wake

24:45

up call and basically

24:48

bumped the need to de-risk because

24:51

the concentration, I mean, in our

24:53

three years of actively engaging the market,

24:56

we found just one crystal

24:59

and silicon module maker that wasn't

25:01

dependent on Asian based aluminum frames.

25:04

So it is 98% of the supply is

25:06

coming out of Asia, most

25:12

of it's China. And

25:14

they're realizing that they

25:16

can't manage the risk because when you have

25:19

the unpredictability of tariffs

25:22

and trade issues and tensions

25:24

across the Pacific, there's

25:27

no good way to hedge that risk.

25:29

And the beauty is with steel frames,

25:32

we can scale. We can scale

25:34

and there is no constraints, material

25:37

constraints with the

25:39

supply chain that we've put in

25:41

place. And so we can drive

25:43

a solution that brings a lot

25:46

of ancillary values like

25:48

domestic content, higher performance and lower

25:50

carbon. But

25:53

it's been amazing how we're

25:56

engaging with the market and

25:58

the vibration has grown dramatically. in

26:00

the last three months, just saying, this is a problem

26:02

we got to solve and solve quick. So

26:05

on the developer-installer side,

26:08

Greg, what are the

26:10

big questions people have? I'm sure they want

26:12

to know about corrosion. You know, you've just

26:14

gone through corrosion and load testing. So

26:17

what are the sources of uncertainty around

26:19

a new product? We are

26:21

actively engaging with all the big EPCs,

26:23

developers, asset owners, and we're actually at

26:25

CBA last, I think it was last

26:27

week. Really

26:29

trying to get everybody aware of the

26:32

value proposition of steel frames, get their

26:34

questions answered. And if

26:36

I just unpack this, the

26:39

EPCs love the

26:42

improvement in performance. We've

26:45

gotten lots of stories about how many modules are

26:47

broken just installing them

26:49

on trackers. And the

26:51

ability to give them a more robust

26:54

frame, that is, as one

26:56

said, doesn't feel like a pool noodle. It

27:00

is very, very, very

27:02

positively received. They're

27:04

concerned about the weight, but we can solve that. We walk them

27:06

through the exact increase in weights and

27:08

they say, okay, that's not an issue. And

27:11

so from an EPC perspective, we're getting

27:13

tremendous thumbs up on how a higher

27:16

performance steel frame can

27:19

improve the ability to get projects in the ground.

27:23

On the developer side, very excited

27:25

about the domestic content, surprisingly excited,

27:27

don't know how to monetize, but

27:29

surprisingly excited about the decarbonization, because a

27:31

lot of their money is coming for folks

27:33

that make that a priority. But

27:35

they're interested. They want to understand corrosion.

27:37

They're very excited about our performance issues

27:40

with weather, but corrosion. And so we're

27:42

spending a lot of time walking them

27:44

through why the

27:46

zinc aluminum magnesium coatings that

27:48

I'll shorten to ZAM, as

27:51

I talk about it more, it's been

27:53

around for decades. And it's

27:55

got industry experience

27:58

that gives everybody comfort. and a

28:00

whole library of third-party independent corrosion testing.

28:02

And we've been doing it, they've been

28:05

doing it. And so the

28:07

corrosion issue we have to address,

28:10

but we've never not gotten past that

28:12

as we get everybody educated. And

28:15

so the benefit there, and

28:17

as everybody starts internalizing, you

28:19

know, fragility issues as the cost down

28:22

on thinner glass and

28:24

smaller frames that

28:26

fundamentally reduce the

28:29

ability to withstand weather, this is one

28:31

of the main ways that this could

28:34

be solved. Also, just

28:36

talk about the difference in weight,

28:38

does that impact the performance of

28:40

trackers with a heavier frame? We've

28:42

talked to virtually every major tracker

28:44

company, and the increase

28:46

in weight is basically the

28:48

conclusion it's immaterial. There's more

28:51

project and site-related variables than the

28:53

weight gain that has

28:55

to be addressed. So it

28:57

truly is not a problem.

28:59

We're competing with aluminum, which

29:01

has got 60 years of

29:04

run-out to do. So there

29:07

are ways that we're going to improve

29:09

steel frames over time, both

29:12

in terms of cost, performance, and

29:15

optimizing things like weight that

29:18

will be showing up literally within a year

29:20

or two. MJ, we're going to

29:22

surpass a terawatt

29:24

of manufacturing capacity

29:27

globally. Talk about the complexities

29:29

of dropping a new frame

29:32

design into that very large

29:34

sector, and then I'll get Greg

29:36

to respond. Well, the

29:38

complexity is, you know, getting

29:41

folks to adopt something new at this

29:43

point. There's a lot of incumbency.

29:47

There's a lot of folks that feel

29:49

like, hey, this is something that

29:51

works and needs

29:53

to be shown, as I'm sure Greg and

29:55

his team are doing, the

29:59

data and the data. analysis that

30:01

shows that this is a superior

30:03

solution, both in terms of performance

30:05

but also cost, because the

30:08

cost pressures are still incredibly

30:10

prevalent in the industry as

30:14

a whole. That being said, I do

30:16

think that solar has always been

30:18

an industry that

30:20

when there is a

30:23

superior solution, it doesn't take long for

30:25

folks to start to adopt

30:27

and realize and try to adopt

30:30

it because they need to also respond

30:32

to those competitive pressures as well.

30:35

One thing that I think will

30:37

be exciting to watch too is

30:40

that something like origami solar with

30:42

a new technology, new

30:44

way of doing something, at the

30:46

same time ramping up as US

30:49

manufacturing as well, I

30:52

think that is something that will be, again,

30:54

exciting to watch because it's historically

30:57

been challenging for a lot

31:00

of the designs, a lot of the thoughts, a

31:02

lot of the US specific challenges

31:05

to be addressed when the manufacturing is

31:07

8,000 miles

31:09

away and the people that are designing

31:11

it are not in the

31:14

fields looking at US

31:17

specific topologies, climate issues,

31:19

hail damage. This

31:23

ability to have local manufacturing

31:27

for technology innovators in the

31:29

US to first of all be able

31:31

to visit a facility

31:33

down the road instead of 8,000 miles away requiring a visa

31:39

is going to help in terms

31:41

of accelerating the cost

31:43

down, the performance gains for those

31:45

innovations as well as help be

31:47

able to commercialize these innovations much

31:49

more easily. So I think that's

31:52

one of the really good knock

31:55

on effects of having local

31:58

manufacturing ecosystem build up. as well.

32:30

We have a lot of different types of framing

32:32

cell automation to be able to put the

32:34

frames on laminate. And they

32:36

sure don't want to have to go to market and

32:38

try to develop new standardized installation

32:40

methods on any segment

32:42

residential through utility. So

32:44

our design was absolutely developed

32:48

to make it a seamless transition. And

32:50

so that nobody's really going to see or

32:52

notice the difference between the aluminum frame

32:55

they mounted yesterday and the

32:57

steel frame they mount today. And

32:59

I also see the strategic benefits in

33:01

my 40 years of business and engineering

33:05

that when you get closer to your

33:07

customers, just like the automotive industry

33:09

did, when back in the 70s and 80s

33:11

when the European and the Asian, primarily

33:17

Japanese auto companies came to the US, they

33:20

got intimate with the market needs. And

33:22

I believe that'll happen as

33:24

we create regional supply

33:27

chains. You'll be able to understand exactly

33:29

what each region does because Europe and

33:31

the US and Asia and India are

33:34

all going to be really, really different markets

33:37

in terms of what you really need to solve.

33:40

We have another example of

33:42

a solar technology that has

33:45

been reshored and that is trackers. And

33:48

steel has been critical for the growth

33:51

of that industry. Greg, any corollaries

33:54

to the tracker market? Like

33:57

can module frames follow trackers? There's

34:01

absolutely similarities. One,

34:05

it's the proof buying that says how quickly

34:07

you can reshore and create the local

34:09

jobs and economic upsides without

34:11

any material negatives for the solar

34:13

industry. And in

34:15

fact, reshoring and using steel

34:19

accelerates and increases confidence in project

34:21

development and construction by

34:23

shortening the supply chain materially without

34:25

concerns about logistics costs or uncertainties

34:28

in delivery. And given

34:30

the bottlenecks we have continued to have

34:32

on all the ports and with the

34:35

random aspect of customs

34:37

quarantine, it gives confidence.

34:39

It actually improves

34:41

the execution in the region.

34:45

But the one difference between us and

34:47

the tracker company is that

34:49

we are taking advantage

34:52

of a material cost difference. We're

34:54

not just reshoring the same material

34:56

to the US.

34:58

We're actually reshoring using

35:01

domestic steel, which has traditionally

35:03

been about the cost of

35:05

aluminum. So we

35:07

get to bring in a new

35:10

metal, reshore

35:12

the production of that, build

35:14

the worldwide global competency center for it

35:16

here, instead of following

35:18

and hoping to leverage from the Chinese. But

35:22

how do we do that? And we can

35:24

do that because of the inherent benefits and

35:26

cost effectiveness of steel. We can do that

35:28

at parity and eventually materially lower cost without

35:31

sacrificing the performance and

35:34

the decarbonization that

35:36

comes with aluminum. I

35:38

want to just add here, on the tracker

35:40

side, if you talk to some

35:42

of the leading tracker players, they

35:44

had these plans to onshore more

35:48

manufacturing here before something like the

35:50

Inflation Reduction Act was even passed,

35:53

just for all the reasons that

35:55

Greg just talked about, carbon, logistics,

35:57

bringing supply closer to demand.

36:01

And then, of course, you add

36:03

the federal tax credits in the Inflation

36:05

Reduction Act, and suddenly, that

36:08

just accelerates everything. And similarly,

36:11

we've seen the same things for solar modules

36:13

as well. MJ, you

36:15

talked about some of the reshoring

36:18

generally that's happening in the US. I

36:20

guess just a blunt

36:22

question on that. Are domestic content requirements

36:24

working? How are they working? Yeah,

36:26

I mean, specifically focused on

36:29

the domestic content bonus credit

36:31

for the ITC, PTC, and

36:33

the Inflation Reduction Act talk

36:36

about more alphabet soup here.

36:38

I think we've had more clarity just in

36:41

the past couple of weeks with some additional

36:43

guidance that's out from Treasury. There's

36:45

this new elective safe harbor option that

36:50

really gives kind of certainty of values

36:52

that the tax equity community has really

36:55

been looking for. So as a result,

36:57

we do think that there are projects

36:59

that are going to be moving

37:02

forward as a result. It's

37:04

a step in the right direction, though. There's still a

37:06

lot of things that need to be fixed in

37:09

certain that Treasury and the folks that are

37:11

helping them pull together this, to

37:14

pull together a proposal

37:16

in the future are thinking about.

37:19

But one of the challenges is that right now, it's a

37:22

static table. It

37:24

doesn't really contemplate many

37:27

of the exciting innovations that are going

37:29

to come, whether it's things like tandem

37:32

solar cells or even just what origami

37:34

is trying to introduce to the

37:36

market. Right now, the values

37:39

are based off of a standard aluminum

37:41

frame. Well, what if origami brings something

37:43

different to the table? How is that

37:45

being looked at independently of the incumbent?

37:48

So those are some of the improvements

37:50

that we'll continue to work on with

37:52

the industry and with the folks in

37:54

the administration to try to solve

37:57

and really help domestic

37:59

content. reach its full potential.

38:01

And Greg remind us, how does the module frame

38:04

play into the domestic module

38:06

content tax credit? Well, it's material.

38:09

The only thing bigger, like I

38:11

say, let's say we're a tie with a glass. The

38:14

only thing bigger is the solar cells.

38:17

And so if you look at what

38:19

is the easiest low hanging fruit to

38:21

drive a material increase, it's

38:23

the frame. And shifting to steel

38:25

frames gives you all the ancillary benefits I've

38:27

mentioned. But it is material.

38:30

And I can't tell you how many

38:32

customers that we're talking to. And

38:36

they're telling the procurement team,

38:39

I need more domestic content. Get this

38:41

done. Because it's important

38:43

to their customers, the developers, ultimately

38:45

asset owners, et cetera, that

38:48

really want to take advantage of

38:50

that. The playing field is not

38:52

exactly fully clear, as MJ mentioned.

38:55

But the trend and the

38:57

strategic intent of that domestic

38:59

content is playing

39:01

out in terms of real decisions

39:04

and motivations on how do we drive

39:06

that domestic and reshoring effort.

39:09

So to wrap up with a big picture question, in

39:13

your op-ed Greg, you

39:15

asked a really simple question, which was, so

39:18

are we serious? Are we committed

39:20

to building a safe, secure, and

39:22

transparent domestic supply chain? Are we

39:24

serious about decarbonization? Are we

39:27

serious about shoring up our immense

39:29

vulnerabilities? When you ask, are we

39:31

serious, who are you referring to? Well,

39:34

it truly is the module manufacturers,

39:36

but it links to virtually the

39:38

entire industry, the people that are

39:40

going to be building these large

39:42

projects. They've got to

39:44

be, as I look, think about it, solar

39:47

has to mature the

39:49

hell up, if I use that term. If

39:52

we're going to be the backbone of the future grid,

39:54

which is what everybody believes is the right answer, we've

39:57

got to really understand. literally

40:00

how will it perform? So

40:03

we're asking the entire industry. And

40:05

to a degree, we're asking the

40:07

questions that says, can you scale

40:10

to be the backbone, first and

40:12

foremost? Two, will you deliver over

40:14

the long haul the performance you

40:16

need to be that backbone? And

40:19

are we gonna get really serious? Like MJ

40:21

said, I view the

40:23

carbon content as a brand

40:25

tarnisher. And we gotta

40:27

get out of that brand tarnishment

40:30

effort. And so we have to

40:32

get the entire industry aligned. But

40:35

the ancillary benefits that come with

40:37

these questions and the shift, not

40:39

just in frames, but across the

40:41

entire solar supply chain and technology

40:43

suite, it is we will

40:46

have a more robust, scalable,

40:48

higher performing energy

40:50

grid. And that's what we're looking for.

40:53

And so it's to the entire industry

40:56

that ultimately has to rally

40:58

around these fundamental questions. Whether

41:00

we're serious or not, we have

41:02

to be. Because these pressures are

41:05

just going to continue to come

41:08

at the industry. I think just from

41:11

looking at the past few years, there's

41:14

a much more serious engagement on

41:16

the topics of supply

41:19

chain diversity, security, being

41:22

able to know that we control

41:24

our own IP and destiny. That

41:28

is the direct result of all the

41:31

supply chain shocks that have

41:33

happened over the past few years. I

41:36

also think there's a level

41:38

of seriousness and maturity that we're

41:40

forced to take now. Steven,

41:43

Greg, I think we all join the solar

41:45

industry probably around the same time, probably

41:48

at this point, have close, if not more than

41:50

two decades in the industry. And

41:52

I feel like for so long in our

41:54

careers, we're always like, well, when is solar

41:56

gonna be at the adult table? We're always

41:58

at the kids' table. is the technology of

42:00

the future. Well, we're becoming the

42:03

technology of the now, which is in

42:05

some ways great, but it also means

42:07

that we are at the center of

42:10

policy, politics, big

42:12

forces, macroeconomic tensions,

42:14

macro trade tensions.

42:17

This is all centered around solar

42:19

because it is the technology

42:22

of the future. And so if we

42:24

aren't serious, then we don't have a

42:26

future. So I

42:28

think we're getting there. There's still

42:30

a lot of work, both for

42:32

policymakers, industry, all the stakeholders

42:35

around. In

42:37

some way or another, we're gonna force we get there. If

42:40

I'd summarize, there is no energy

42:42

transition without energy independence.

42:45

And there is no energy

42:47

independence without robust decarbonized domestic

42:50

supply chains. That's the

42:52

logical progression to me. There

42:54

you have it, a very

42:57

good wide ranging conversation about

43:00

these macro changes in the solar industry as seen

43:02

through the lens of the PV

43:04

module frame. And that was Greg

43:07

Patterson, who is the CEO of Origami

43:10

Solar. Greg, thank you so much. That

43:13

was great, Steven. I really appreciate that. And MJ,

43:15

I'd love hanging out with you. Anytime.

43:19

And MJ Shao is the VP of

43:21

supply chain and manufacturing at the American

43:24

Clean Power Association. Thank you, MJ. Thanks

43:26

for having me. This conversation was

43:28

recorded live as part of Latitude

43:30

Media's Frontier Forum with Origami Solar.

43:33

This was a lightly edited version

43:35

of the conversation. If you wanna

43:37

watch the full video, head on

43:39

over to latitudemedia.com/events and click

43:41

watch recording. And if you

43:43

wanna read some additional coverage about the transition to

43:45

recycled steel, we've got some links in the show

43:47

notes so you can follow up and do some

43:49

reading of your own. Thanks for

43:51

listening. I'm Steven Lacy. Thank

43:55

you, continue

44:00

you

From The Podcast

The Carbon Copy

A narrative news show about the trends shifting our carbon-based economy. Each week, host Stephen Lacey digs into the business and technology stories that explain the rise of clean energy, the challenge to fossil fuels, and how the energy system is transforming in dramatic ways. Produced by Latitude Media.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

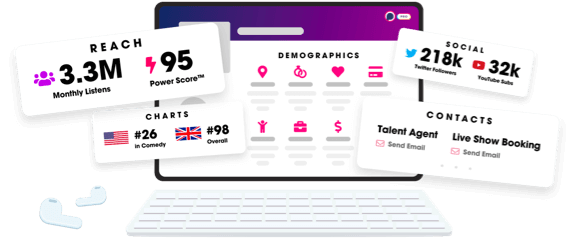

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us