Episode Transcript

Transcripts are displayed as originally observed. Some content, including advertisements may have changed.

Use Ctrl + F to search

0:05

Hello again everybody . This is Fred Crans from

0:07

St Onge . We're here today with another

0:09

episode of Taking the Supply Chain

0:11

Pulse . Today we

0:14

have a first . Today we have the first

0:16

time that I've ever had someone

0:18

on the podcast for the second time

0:20

, but there has to be an asterisk by

0:22

it , because you could not possibly

0:25

have heard the first recording

0:27

because I forgot to press the record

0:29

button . So today , two

0:31

days after our first attempt , kim

0:34

Jones , who is a nationally

0:36

recognized central sterile supply

0:38

expert , is going to be talking with us

0:40

about her experiences in

0:42

life and central sterile supply

0:44

, starting out in human resources and

0:46

all kinds of good things , and she's well

0:48

rehearsed because we did this for 30

0:51

minutes two days ago . Kim , thanks

0:53

for coming back and giving me a second chance

0:55

.

0:56

Well , thank you , fred , and thank

0:58

you for you setting me

1:00

up there . I better not make any mistakes , since

1:02

everybody knows that I already had one try

1:04

at this . So , we'll both

1:06

try to do our best , but I appreciate the

1:09

opportunity to join you today . Thank

1:11

you .

1:12

Yep , and if you're not making mistakes , you're not trying

1:14

. Okay , You've got to get out there and get in the fray

1:16

. So I'm glad to have had

1:18

that was a great conversation the other day and

1:20

I really learned a lot talking to

1:23

you about central sterile . So why don't you tell

1:25

us about yourself , your background , how you

1:27

got started and how

1:30

you've worked to where you are today ?

1:32

Sure Well , thank you . I

1:34

obviously started

1:37

my career not

1:39

in sterile processing but , as you mentioned

1:42

, I had the good fortune right

1:44

out of college to find a position

1:46

in human resources with

1:49

a very well-known organization

1:51

here in central Ohio . I

1:56

got that position as a

1:58

recruiter in HR and

2:00

my areas of accountability

2:03

were sterile processing in the operating room

2:05

. So I always say of

2:07

my 30-year career , the majority

2:09

of it has been spent in sterile

2:11

processing in

2:16

the operating room in or around those areas

2:18

. So you may ask

2:21

how that goal

2:23

or how that position in human resources

2:25

ended me up in sterile

2:27

processing . I

2:30

worked for a few years supporting the

2:32

operating room and sterile processing from an HR

2:34

recruitment perspective

2:37

, as well as some employee relations mixed

2:39

in there . I went out on

2:41

maternity leave to have my first baby

2:44

and when I came back there was

2:46

an SPD educator position that had

2:48

been writing my position roster

2:51

the entire time I was out . So I

2:53

met with the director , who I had a great relationship

2:56

with , and we walked through the department . I

2:58

was trying to get from her what exactly

3:00

she was looking for so that it would

3:02

help me to better recruit for

3:04

them , and by the end of that

3:06

visit you know I was pretty fascinated

3:09

by all of this reprocessing

3:11

that happened . I obviously knew part

3:14

of the job because I recruited for

3:16

it , but at the magnitude and

3:18

the volume that

3:20

facility was a 32-room OR

3:23

and so it was just an immense

3:25

operation . And so at the end

3:27

of that visit , at the end of that

3:29

conversation , the director

3:31

pitched the idea hey , why don't you

3:33

take this position ? People respond

3:36

well to you , you're teachable , we can

3:38

teach you the business . You

3:40

have the people skills . So that's how it kind

3:42

of started . So my first position

3:45

was an educator . That was back

3:47

in around 2005 , 2006

3:49

. There was a big push , lots

3:52

of lobbying going on to make

3:55

certification mandatory in

3:57

New York and New Jersey at that time , and

4:00

so we were leading the pack

4:03

in central Ohio . I

4:06

became certified , wrote an

4:08

education program and we were

4:10

able to get about 70% of the staff

4:12

certified at that time

4:15

and I really , really enjoyed

4:17

watching people respond

4:20

, as they were learning why

4:22

we do the things we do , not

4:24

just how we do the things that we do

4:26

in sterile processing . So I held

4:28

that position for several years

4:30

and then I really started to get interested

4:33

in operational leadership . So a manager

4:35

position in that very department became

4:37

available , so I threw my hat in the ring

4:39

and I was given that position . I

4:42

had a large number

4:44

of FTEs about

4:46

80 full-time FTEs

4:48

that reported up through me and I

4:50

held that position for

4:52

a few years three to five

4:55

years I believe and then I was actually invited

4:57

to join the OR

5:00

team as a non-clinical manager

5:02

in the operating room , and that was really a gift

5:05

to me being able to

5:07

see the full cycle of how the patients

5:09

come in and how the work that we

5:11

do in sterile processing can affect the

5:13

metrics that the operating room

5:16

uses to remain

5:18

efficient . And so

5:20

I was really able to see how

5:23

that ecosystem of perioperative

5:25

services includes sterile

5:27

processing and I ended

5:30

up having the non-clinical

5:32

team , at first anesthesia techs , or

5:34

techs you know anything non-clinical

5:37

in the operating room reported to

5:39

me . And then halfway through my tenure

5:41

there I was given

5:43

the clinical staff and then halfway through my

5:45

tenure there , I was given the clinical staff . I had off shift clinical teams

5:48

, afternoon , evenings and weekend

5:50

clinical teams , and

5:52

that was great because you know , as

5:54

a sterile processing leader , we often hear

5:57

the complaints of the operating

5:59

room . But

6:06

once I was able to lead those clinical staff I was able to understand how five

6:08

minutes of a wait affects their entire process in the operating room or how delays

6:10

from a sterile processing perspective can

6:12

back the schedule up and the surgeons

6:14

then have to operate with a whole new team

6:17

because their first shift team leaves . And

6:19

so all of that just kind of helped to

6:21

enable my thought process

6:24

and also continue to feed even

6:26

though I wasn't in sterile processing anymore

6:28

. Just the importance of sterile

6:30

processing and a fluid , efficient

6:33

process in sterile

6:35

processing will then translate to the

6:37

same in the operating room . I

6:40

held that position for a few years and

6:43

then I was actually recruited

6:45

to another central Ohio

6:47

health system who is quite

6:49

large . There I

6:51

was accountable for 49 ORs

6:54

and for major

6:56

hospitals under one roof

6:58

, if you will , and then

7:01

acquired a community hospital

7:03

and several same day surgery hospitals

7:06

. And while I

7:08

had my tenure there

7:10

I was able to work with the St

7:13

Ange team and we

7:15

developed an

7:17

offsite reprocessing center . And

7:20

that was really

7:22

kind of taking all of my experience

7:25

and putting it into

7:27

something new and innovative

7:29

, and that was a really

7:32

great experience being able to

7:34

see that process from start to

7:36

finish . So

7:45

then I left that organization and thought you know what

7:47

am I going to do with all of this experience that I've gathered ? And I threw

7:50

my hat in the ring for some consulting and I

7:52

started my own consulting firm

7:54

. And you know

7:56

I've had the good fortune of working with

7:58

several large IDNs

8:01

across the country over the

8:03

last year and a half

8:05

. Projects ranging from process

8:07

improvement with high-level

8:10

disinfection , team

8:13

building , leadership

8:15

, mentoring

8:17

, leadership development , change

8:20

management , had

8:23

some opportunity in the last

8:25

year and a half out on my own to

8:27

be able to contribute to equipment

8:29

planning and some standard

8:31

operating procedure writing for

8:33

a very large IDN looking at building

8:36

an off-site reprocessing center . And

8:38

then I most recently finished up again

8:41

with the good fortune of being

8:43

partnered with St Onge to work for

8:45

another very

8:47

prestigious IDN that's mostly

8:50

here in Ohio

8:53

doing audits on process

8:55

improvements , taking

8:57

a look at opportunities to standardize

9:00

, and that was a very

9:03

large project . We had a tight

9:05

timeline and

9:07

, you know , continued to just be able

9:10

to use the skills that I have

9:12

in partnership really has just

9:14

helped me take all of my experience . And what

9:28

I enjoy the most about what I do now is

9:31

when I go into a new place

9:33

and there's perhaps a director

9:35

that's struggling or

9:37

a director that feels

9:39

like they're at the end of their rope . They've tried everything

9:42

. It's really

9:44

gratifying to be able to say you

9:46

know , I've been in your seat and I've sat

9:48

in your chair and I know how you're feeling , and

9:51

to be able to contribute to their success

9:53

has been something that I've really enjoyed

9:56

over the last year and a half . So

9:58

that's where I am now .

10:00

Great . Well , you have a unique

10:03

collection of experiences

10:05

. Starting out , the HR

10:07

experience really comes into play

10:09

here , because paid lowest appreciated

10:12

, least appreciated folks in the hospital

10:26

. And when

10:29

you see that , there's another thing

10:31

that you understand that many people don't

10:33

, and that is that the dependencies

10:35

. The OR can't do surgery unless

10:38

CS does its job . Cs

10:40

can't do its job unless the

10:43

supply chain fulfills

10:45

their needs to get CS the equipment

10:48

and supplies they need to do their job . There

10:52

are these relationships and yet my

10:54

experience , and as I said

10:56

the other day , my friend Ed Hiscock

10:59

said there are many supply chains

11:01

in health care , not just one . There's

11:04

a supply

11:06

chain , there's a pharmacy supply chain , there's

11:08

a food service supply chain , there's an

11:10

environmental service supply chain . Every

11:13

department or every

11:15

function likes to be standalone

11:17

and take care of its own problems and my

11:20

observation I'll take this off your shoulders

11:22

my observation over the years is

11:24

that OR is always fighting with CS

11:27

, OR is always fighting with the

11:29

regular supply chain . What

11:31

do you see as the

11:35

most frequent disconnects among

11:38

these three organizations OR

11:40

, CS and the regular supply

11:42

chain and how do

11:44

you go about working to

11:46

improve those ?

11:48

I can 100% agree with you

11:50

and I do feel like my experience

11:53

has given me the opportunity

11:55

to see different veins

11:57

of this supply

12:00

chain , you know , when

12:03

they're highly functioning and

12:05

the communication is high functioning , and

12:08

then I've had the opportunity to see

12:10

where there's lacking . And again to your

12:12

point , where there's the finger pointing and

12:14

everyone wants to pass the buck

12:16

, which is human nature . And I think that

12:19

my time in the operating room

12:21

gave me the opportunity , as

12:23

I mentioned earlier , to see

12:25

how important all

12:27

of the supporting departments for the operating

12:30

room truly are , and I

12:32

was able to also see the pressure that

12:34

the OR was under to make things happen

12:37

and to make them

12:39

happen on time . To answer

12:41

your question simply , Fred , I believe

12:43

that a lack of understanding of

12:45

what our independent roles

12:48

actually are

12:50

accountable for and some of the barriers

12:52

that within those independent

12:54

entities sterile processing

12:56

, operating rooms , supply chain some

12:58

of the barriers that exist within

13:02

our own personal sets of accountability

13:04

, are often not articulated out

13:07

. So what I mean by that is what

13:10

I've seen in organizations is a lack

13:12

of partnership in those three major

13:14

entities so the operating room , the sterile

13:16

processing department and supply chain

13:18

and I believe that that happens from the top

13:20

down . So if you

13:23

have collaboration among the leaders

13:25

with operating rooms , sterile processing and

13:27

supply chain , as leaders

13:29

we are accountable to push that down . And

13:31

there we are accountable then to

13:34

stop the blaming , stop the finger

13:36

pointing . And how that happens is

13:38

frequent meetings , frequent

13:40

touch bases , open lines

13:42

of communication , being

13:45

able to have a mechanism to

13:48

proactively let

13:50

the departments that enable

13:52

our success know hey , we've

13:54

had a ton of call offs in

13:56

the last 24 hours . We're

13:58

going to have your first cases ready for you

14:00

. Our manager will

14:03

keep in close contact with you throughout the day

14:05

to let you know what it's looking like for us

14:07

. And then having an operating

14:09

room leader that understands and respects

14:11

that and says what can we do to help you

14:13

? We get that . You're having some

14:16

issues today . The same thing that

14:18

and that's on the frontline level . The same thing can happen . The

14:20

that's on the frontline level , the

14:23

same thing can happen and I've

14:25

seen it function very well

14:27

. Supply

14:34

chain , having a adequate mechanism to inform when we have back stocks

14:36

, when something's been replaced , when locations have been moved . And again

14:39

, I believe that all of that comes

14:41

from the top down . So organizations

14:44

must task their leaders with

14:47

open lines of communication

14:50

, support and

14:52

when and where a

14:54

toxic environment exists . Sadly

14:57

, everyone from

15:00

the top down feels

15:03

that toxic environment

15:05

and that just contributes to the lack

15:07

of accountability and

15:09

the blame game . So I

15:12

believe that the largest disconnect is

15:14

communication , as well as education

15:16

about what the

15:19

enabling departments are accountable

15:21

for , and an openness and

15:23

a willingness to support

15:27

one another in times when we're

15:29

overtasked , we're stressed , we have

15:31

, you know , a lack of resources

15:33

. From a people perspective , I

15:35

think that you know we can't be afraid

15:37

to just reach out and say , hey , I need some

15:40

help .

15:41

Yeah , you know I'm listening to that

15:44

and I'm thinking of the OR

15:46

environment , if you will , and

15:48

I'm probably showing my age when I talk about

15:51

this , but when I first came into

15:53

supply chain , you know , the OR

15:55

nurse was sort of at the tip

15:57

of the spear , if you will . The

16:01

OR produces a significant

16:04

amount of revenue . Many of the highest

16:06

and best reimbursed

16:08

procedures are done in the OR

16:10

, so they got to get them done . That

16:13

OR director is working with people who

16:15

have egos that don't fit in most buildings

16:17

and who historically

16:20

, up until recent years , have

16:22

always had the leverage to get

16:24

what they want when they want it , not

16:27

get what they need when they need it , which is an entirely

16:29

different thing . So it becomes

16:31

really important

16:33

to build relationships and

16:35

to educate the clinicians and

16:38

the doctors . How have you gone about doing that

16:40

?

16:41

You know I've had the good fortune in

16:44

the organizations that I worked

16:46

for that you know , the sterile

16:48

processing managers sterile processing

16:50

director , you know , is

16:53

the first line of defense really

16:55

for the team . So I've had the

16:57

good fortune that in

16:59

both of the organizations I spent

17:01

my entire tenure , surgeons

17:04

were very vocal when they

17:06

had an issue . You

17:08

know , in one experience I had

17:11

vocal surgeons

17:13

who would , to your point , go to the OR

17:15

manager , or director , and

17:18

the OR director would come to me give me the

17:20

opportunity to fix it , and

17:22

there was that open line of communication

17:25

and so the surgeons , we

17:28

partnered together and

17:30

that didn't start off in the very beginning

17:32

. I think you have to earn that , you

17:34

have to earn their trust and I

17:37

think by in so doing you

17:40

are then able to have their

17:43

trust that you're handling an

17:45

issue . What

17:47

is very important to make sure

17:49

that that cohesive relationship and

17:52

that trust factor is

17:54

created in a very authentic

17:56

way is that the operating

17:59

room leaders have to support the sterile processing

18:01

leaders , otherwise the

18:04

surgeons , to your point

18:06

, you know it takes a huge ego to take

18:08

somebody into a room

18:10

and essentially have them

18:12

, you know , dead

18:15

on the table really to

18:17

fix their problem , patch them

18:19

up , sew them back up . That

18:22

takes a huge amount of

18:24

confidence and ego . So that

18:28

that takes a huge amount of confidence and ego . So you know , it kind of

18:30

goes with the territory . However , I believe that they're still

18:33

human beings and they still need

18:35

to understand the why behind something

18:37

. If I don't have the support

18:39

of an operating room leader , when I

18:41

go to a surgeon and try to explain the why

18:44

in my department , he feels

18:46

that I'm just not taking accountability because

18:50

it hasn't been . There's

18:53

not a cohesive relationship between

18:55

the seroprocessing leader and

18:58

the OR

19:00

and the trust is there

19:02

. When that surgeon goes and

19:05

he is complaining again to the OR

19:07

leader , I

19:14

get the call hey , dr So-and-so is upset about such and such . We backed

19:16

him off , but hopefully you can look into this and let me know what's going

19:18

on . End of story . And so I

19:21

think that you know that

19:23

in and of itself is a huge

19:25

challenge . And when I'm out

19:27

in , you know , across the country , working

19:29

with sterile processing leaders , one

19:31

of the first questions I ask them is what

19:33

is the , what's your support like from the OR

19:35

? Because without that support

19:38

we've got a lot of work to do in sterile processing

19:40

and as a sterile

19:42

processing leader . But when , when

19:45

a leader is able to tell me that they do

19:47

have tremendous support , then

19:49

you know half the battle is won

19:51

then , because then it becomes

19:53

process improvement , team building within

19:55

our own entity . That takes a lot of time

19:58

, it takes a lot of , you know , accountability , it

20:25

takes a lot of education .

20:26

So you know , I think the sheer nature of what I do and that that question

20:28

being a primary question , shows you

20:30

how important communication is and and just trust and collaboration , yeah , but that's

20:33

that's the problem that's got to be solved , that's for sure . So , when you work

20:35

with St Onge on a couple of really large projects

20:37

one was the development of

20:39

an off-site processing center and the other one was an audit of a very prestigious

20:42

systems sterile processing

20:44

function when you work on , when

20:46

you walked into these places , places who

20:49

we mentioned their name we go , oh

20:51

my God , that's really something . What

20:53

did you discover in there that surprised

20:56

you ? And what stuff did

20:58

you discover that didn't surprise you ?

21:02

I think that what surprised

21:04

me was that

21:08

these prestigious organizations are

21:10

still working under a very archaic

21:12

assumption that sterile

21:14

processing is simply washing

21:17

items

21:21

. You know Toyota Lean

21:23

, six Sigma . You know , if

21:26

we implement Lean

21:29

processes then we should be perfect

21:33

. And I believe that in

21:35

one scenario that was the

21:37

belief of one of the health systems

21:39

. And what happened in

21:42

that scenario was , you

21:44

know , making a car with the Toyota

21:46

Six Sigma prescription

21:48

is much different than

21:51

getting a tray down from

21:53

the operating room with 100 parts and pieces

21:55

and having to sift through that

21:58

. There's no assembly

22:00

line because there's no

22:02

taking into account that the peripheral

22:04

processes that enable sterile

22:07

processing success have not

22:09

been addressed prior to implementing

22:12

such a system . That

22:14

is believed to be assembly

22:16

and foolproof . And

22:19

if we just do it the way it's prescribed

22:21

, then we should be able

22:23

to be deemed

22:25

successful . And I

22:28

was surprised that one

22:30

of those organizations still felt

22:33

that that was the answer to the issue

22:35

, without looking at the

22:37

peripheral processes . Was point

22:39

of use cleaning happening in the OR

22:41

? Was the OR sending trays back

22:43

complete to sterile processing ? That

22:47

was not a consideration , and

22:49

so sterile processing was set

22:51

up to fail in that

22:53

scenario because we had

22:55

not made sure that our

22:58

customers were held accountable to

23:00

do what they needed to do . And

23:02

the other idea and I was

23:04

surprised to see that , you

23:06

know , compensation rates are still so

23:08

low . The infrastructure

23:10

of the department is lacking in

23:13

the areas of education

23:15

, onboarding , educational programs

23:17

, adequate

23:19

numbers of FTEs being

23:21

assigned to a singular leader

23:24

, and that

23:26

still many of the departments

23:29

did not have the adequate resources

23:31

to handle the daily volume . Use

23:33

a metric of procedures performed in surgery

23:36

. That will dictate how many FTE we need

23:38

to process instrumentation

23:52

and sterile processing . And

23:54

what I have struggled

23:57

with for years to try to help administrators

24:00

understand is volume does not equal

24:02

volume . So if have

24:05

30 GI

24:07

cases or general GU

24:10

cases and I have 30 ortho

24:13

cases , there is a vast

24:15

difference in the

24:17

amount of parts and pieces that

24:19

sterile processing is going to be accountable

24:22

for , and so it just

24:24

surprises me . I think , that across

24:26

the country we see that while

24:29

surgery has advanced

24:31

and become very technical

24:33

and very complex

24:35

, and instrumentation has

24:37

also become very complex

24:40

and very innovative

24:42

, we have not taken a look at

24:45

the educational component for

24:47

our serial processing techs . We have

24:49

not taken into consideration how

24:51

much they're actually making . These

24:54

people are under a tremendous amount

24:56

of pressure , tremendous

24:59

and they're still making

25:01

an entry level wage that's

25:03

not much higher than the housekeeper

25:05

in the hospital

25:08

environment . So

25:10

I think those are the things that surprised

25:12

me . I believe that you know , working

25:14

with these two very prestigious organizations

25:17

, that I would see oh , you know

25:19

they got it . They understand that

25:22

. You know , in order to have a successful

25:24

operation , we have to appreciate

25:27

and retain and incentivize

25:29

our sterile processing team , and

25:32

that just was not the case . So

25:34

I think , in a nutshell , that

25:36

was my experience .

25:38

Yeah , and you know , the other day in our conversation

25:41

, when you're talking about the

25:44

low level of pay and the low

25:46

level of appreciation for the difficulty

25:48

of the task in sterile processing

25:50

, you mentioned the fact that folks

25:53

are going outside for other jobs , one of which

25:55

was you can make $19

25:57

an hour at the car wash and you're lucky

25:59

to make $15 an hour at the cart wash , which

26:01

is only one letter difference when you look at it . But the difference is if you screw up at

26:03

the car wash , which is only one letter difference when

26:05

you look at it . But the difference is if

26:08

you screw up at the car wash , you may put

26:10

a scrape on the side of a car . If

26:12

you screw up in the cart wash , you can kill people

26:14

, and it's that

26:16

simple . So that

26:19

sort of transitions to two

26:21

things , sort

26:23

of last part of this conversation . Number

26:25

one is where do you see robotics

26:28

coming into sterile processing

26:30

to assist the people there ? Do you see that

26:32

something that's happening ?

26:35

You know I do a lot of reading , I

26:37

try to stay up on the latest

26:39

technologies and so on and you know

26:41

, in my experience I think

26:44

I shared with you the other day I

26:46

have never managed a

26:48

small operation or directed a small

26:50

operation . I

26:53

believe that you know the

26:57

vast variation

26:59

in tray size and weight

27:02

and movement of our

27:04

own human resources , people actually

27:07

doing the job . I

27:09

have seen where , especially

27:12

in decontamination , where

27:14

there's lots of twisting and turning to get

27:16

things in the sink out of the sink , get

27:23

things in the sink out of the sink Some of that automation using robotics . You

27:25

know there's opportunity to move trays using robots . There's automation

27:28

for trays entering into

27:30

the washer and coming out of the

27:33

washer . I think those

27:35

types of ergonomic robotic

27:38

assistance is going to really

27:41

take off over the next few years . You

27:43

know , as an operational leader with

27:45

a lot of years under my belt

27:47

, seen so many injuries

27:50

or so many ongoing , you

27:53

know individuals that

27:55

can't work in a certain place because they've

27:58

hurt their back too many times , so on and so

28:00

forth . So I do believe that that

28:02

component is

28:04

taking off and I think larger

28:07

facilities are going to start using

28:09

that because ultimately it saves

28:11

the human resources from injury and harm

28:13

. From an AI

28:16

perspective and I don't know if

28:18

that's kind of what we're thinking

28:20

as well being able to dump an entire tray

28:23

out on a pad of

28:25

technology , if you will , and it's able

28:27

to sort of spit out if all

28:30

the contents of the tray are there , that's all well

28:32

and good is

28:46

advanced to this degree , but they'll , in my mind , never be in my lifetime a

28:48

replacement for actual human expertise to take

28:50

a look at these instruments to see if

28:52

their efficacy of the instrument

28:54

is adequate , if the cleanliness is

28:57

adequate . I

28:59

think that we will always rely on people

29:01

to do that job

29:03

. But I do think that technology

29:06

and robotics have grown

29:08

leaps and bounds , and so

29:10

I make that statement

29:12

loosely and could very

29:15

likely be proven wrong in my lifetime

29:17

, that there would be , you know

29:19

, a robot that could do anything

29:21

that a human can do . It's , you know , at this

29:23

point in our history we're

29:26

seeing so many advances , but

29:29

right now I believe strongly

29:31

that the human element of sterile

29:33

processing is very important from

29:37

an inspection perspective .

29:39

So would it be fair to say that

29:42

the shortest list in the world

29:44

might be healthcare

29:46

systems that have sterile processing , in

29:49

which the sterile processing operational

29:51

process couldn't be improved ? And would

29:53

it also be fair to say that

29:55

if you're considering doing anything , you

29:58

start with an assessment and get a real

30:01

good look at what the options are , what the opportunities

30:03

are where your organization's going

30:06

with a strategic plan , and tie

30:08

all that together ? Would that be fair to say ?

30:10

Absolutely , and I think that there

30:12

are technologies that

30:15

could you know , for the

30:17

benefit and the bottom line of an organization

30:19

, if they're going to invest , you

30:21

know , several hundred thousand dollars in robotics

30:24

and a sterile processing department , would

30:26

that yield any savings as far

30:28

as human resources . I believe

30:30

that that is certainly something that

30:33

, from a strategic plan

30:35

, would come into play . Come into play , I do

30:37

believe that , exactly what you said research

30:40

, and you know doing

30:43

some , you know true , evidence-based

30:45

research . Who's using this , how's it working

30:48

for them ? What's the repair rates look

30:50

like ? You know all of that because we know

30:52

that when we rely on , even

30:54

when we rely on our electricity and we're

30:56

hit with a thunderstorm , we got to figure it out

30:58

. Well

31:07

, when you're running an operation that's feeding forty , nine , fifty , two , thirty two

31:09

operating rooms , and you have a piece of equipment go out and sterile processing , it's not

31:11

as easy as just running to find a candle , you know . So I think that all of that has to be

31:14

taken into consideration when we go with

31:16

with new technologies and

31:18

new advances

31:21

in technology . I think we really need to take

31:23

a look at what's that downtime look like

31:25

and how are we going to compensate for

31:27

that If we cut healthcare , human resources .

31:48

The traveling nurses had saved

31:51

the day in many places , quite honestly , depending

31:54

on where the pandemic went , they sort

31:56

of followed that . How

31:58

are travelers showing

32:01

up in sterile processing , and is

32:04

that a thing that needs to be dealt

32:06

with ? Could you talk about that ?

32:08

I sure can . So you

32:10

know , I believe that the travelers

32:13

, the amount of travelers

32:15

that we saw across the country after

32:17

the pandemic and the years that have followed

32:20

, have largely increased

32:22

for sterile processing techs

32:24

, and that is really

32:26

in part due

32:28

to and I think in large

32:31

part due to the compensation . You

32:34

know they can go and they can do this job

32:36

and they can feed their families . They can

32:38

make enough money to pay down debt . They may

32:40

make enough money to put their kids through college

32:44

. They can , in some very

32:46

sad situations , get off government assistance

32:48

when they go and do traveling

32:51

jobs . So

32:53

I really believe that this is very

32:55

cyclical . Did the pandemic

32:57

highlight it ? Very much so . However

33:01

, I believe that the biggest

33:03

problem with retaining , retention

33:07

and recruitment is

33:09

how much these people are being paid . They're being

33:11

asked to be certified or to become certified

33:13

and again they're just making a few dollars

33:16

more than the guy that's sweeping the floor

33:18

in housekeeping , than

33:22

the guy that's sweeping the floor in housekeeping . So when they're asked to , when they join

33:24

in with a travel agency , the travel agency is sending them to

33:26

places where they're very needed

33:29

and they can go

33:31

there and they can make money . And you know

33:33

, my hope is that they feel appreciated when

33:35

they're there . So they feel appreciated and

33:37

they continue to extend their contracts

33:39

. I believe that this problem

33:41

, the root of the problem , is that

33:44

administrators within healthcare

33:46

have never caught

33:49

up with . If

33:51

surgery is going to be the revenue generating

33:53

engine of your health system

33:56

, then what are you doing for

33:58

the people that are feeding

34:00

that revenue generating engine

34:02

of the hospital ? The surgeon can come

34:04

to work and he can have 10 cases lined

34:06

up for that day . That's going to yield the hospital

34:09

hundreds of thousands of dollars

34:11

. But if he doesn't have his basic

34:13

tools in working order

34:15

and in sterile and

34:17

ready for those patients , he's not making

34:20

anybody any money . And in sterile

34:22

and ready for those patients , he's not making anybody

34:24

any money . And

34:28

the OR staff ? They're not educated to do the work of a sterile processing tech . So I believe

34:30

that the disconnect between the people that are actually

34:33

providing the tools for the clinical team

34:35

to do their job to then be the revenue

34:37

generating engine of the health system so

34:39

that the administrators can make their bottom

34:42

line , I think where they are lacking

34:44

is that fundamental first step

34:47

of making sure that your sterile processing

34:49

techs are adequately paid . They're

34:51

appreciated , there's a retention

34:53

program in place for them . There's an education

34:56

program in place for them and

34:58

so many facilities just

35:00

see it as just do more

35:03

. You have a manager

35:05

in the department , so the manager

35:07

can take an assignment today . The

35:10

supervisor can take an assignment today

35:12

. I believe

35:14

wholeheartedly that sterile processing

35:17

is the place where many

35:20

administrators look at where are we going

35:22

to cut some expense

35:24

so that we can then , you

35:27

know , get more scrub techs to scrub

35:29

these additional cases that we're going

35:31

to put on ? We can get more nurses

35:33

to scrub and to circulate

35:36

. They're

35:43

taking from the wrong place , because what happens , as you all know with the history in

35:45

sterile processing , we get behind in sterile processing and who ultimately

35:47

suffers ? Ultimately

35:49

, our patients suffer , but the

35:51

metrics in the operating room start to crash

35:53

the minute we don't have adequate resources

35:56

in sterile processing . So

35:58

I believe that organizations

36:00

that spend hundreds of thousands of dollars

36:02

on travelers it amazes

36:05

me if they would look inward and

36:07

they would take a look and dive deeper

36:09

into why do we have 30%

36:12

travelers in our organization ? Why can't

36:14

we retain people ? You know , if

36:17

you have adequate leadership in place

36:19

, the question doesn't . The blame doesn't

36:21

fall on the leader , it falls

36:23

on the leader can only do what

36:26

they are equipped to do what the

36:28

organization has given them the resources

36:30

to be successful . If you

36:32

are not given the

36:36

really the respect by the organization

36:38

as their sterile processing leader

36:41

, when you go to your administration

36:43

and you say , I

36:45

see what you're telling me on paper , but

36:47

that's not the scenario , I

36:50

think that's where they're shooting themselves

36:52

in the foot and I think that's why

36:54

the traveler , the traveling

36:56

population has exploded . Population

37:04

has exploded . They're not paid enough , they don't feel

37:07

appreciated and it's a never ending cycle in some organizations

37:09

and sadly I've seen that .

37:09

Yeah well , just to sum up , because once

37:12

again we get back to this whole idea of an assessment

37:14

. You know most of my

37:17

experience in health care and probably

37:19

most of yours has been people

37:22

that our

37:25

cases are made narratively

37:27

, without data . I

37:30

need more people in CFs and

37:33

you try to tell a doctor hey , you don't understand

37:35

. There's a difference between this case

37:37

and this case is what it requires , between this case

37:39

and this case is what it requires , Unless you have

37:41

someone in to help you gather the data

37:43

and build the case . All

37:46

you appear to be doing to the people

37:48

in the C-suite is making excuses

37:50

and whining and

37:56

what your recommendation that I've gotten out

37:59

of what we've just been talking about is

38:01

number one for the organization to respect the function

38:03

about . Is number one for the organization to respect the function , uh , number

38:05

two , to provide enough resources to do the job and number three , to

38:07

pay those resources enough so that they won't

38:09

have to become travelers to make money

38:11

to live their life normally . Is that , was that fair

38:14

to say ?

38:15

very fair to say and you know , I understand

38:17

that . You know from an administrative

38:20

C-suite perspective , they

38:22

feel that they should not be

38:24

in the weeds . That you know , sterile processing

38:27

leaders should be able to

38:29

tell the story and , to your

38:31

point , you know , have data to

38:33

back that up . In my experience

38:36

that's 100%

38:38

true . Data is wonderful to tell the

38:40

story . It

38:53

tells part of the story . It doesn't tell the part of the story that point of use , cleaning is

38:56

lacking in our operating room , which requires additional resources in SPD 80 percent

38:58

, 30 percent of what we sent you , you sent it right

39:00

back to us and that took 30

39:02

percent of our resources to

39:05

develop those trays and

39:07

create that case card and

39:10

then it was just basically , you

39:12

know , all for naught , it wasn't needed

39:15

. And so I

39:17

believe that the more we can

39:19

advocate for change

39:22

and assessments and engage

39:24

our administrative C-suite people

39:26

to understand that , while

39:29

some organizations probably you

39:31

know it would be naive to say there aren't

39:33

leaders , that would just , you

39:35

know , pass the buck or blame

39:38

their team or so on there are leaders

39:40

. If somebody has achieved a level

39:42

of director of sterile processing , they

39:45

care about what they're doing and they know what

39:47

they're doing and I believe that they

39:49

need to have the respect of the C-suite

39:51

to sit down and listen the minute the

39:53

problems present and

39:55

they're outside of the realm of that

39:57

director's control or that manager's

39:59

control . The C-suite needs

40:01

to humble themselves and sit and listen

40:03

and not just make

40:06

those assessments from their

40:08

data or historical benchmarking

40:11

. You know all the buzzwords

40:13

that we hear in our industry .

40:16

Well , jim , thank you

40:18

for coming back for the second time Before

40:20

we go . I did

40:23

a big on-site project

40:26

at an organization in the south

40:28

. It must have been around

40:30

2000 , 2002

40:32

. They were returning 45%

40:35

of the stuff that was sent up to surgery back

40:38

unused and that was the stuff that came back

40:41

was sent up to surgery back unused and that was

40:43

the stuff that came back . Remember , what you haven't talked about is

40:45

the stuff that got thrown away because it got opened and had to be thrown away

40:47

, couldn't be used again . But 45%

40:49

was coming back and I was talking

40:51

to those people about three years ago and

40:54

they said that they've worked really hard to implement

40:56

the stuff that we talked about and

40:58

they've got it down to 42% now . So

41:00

they've really made a vast improvement . So

41:02

that's still . The problems are still there

41:04

. But , kim , thanks so much

41:06

for shining the light on sterile processing

41:08

. This has been a great conversation and

41:11

I appreciate the fact that you put up with an old

41:13

guy who is too stupid to press

41:15

the record button and we hope to have you

41:17

back again in the future . Thank you so much .

41:20

I would be honored , fred , and thank you , have

41:22

a great day and we'll talk soon

41:25

.

41:25

Okay , take care , see you Bye .

From The Podcast

Taking The Supply Chain Pulse

St. Onge’s Healthcare Hall of Famer and industry icon, Fred Crans, chats with leaders from all areas of healthcare to discuss the issues of today's- threats, challenges and emerging trends and technologies in a lighthearted and engaging manner.ENGINEERING A BETTER HEALTHCARE SYSTEMWe provide comprehensive planning and design services to develop world-class facilities and highly effective support services operations. Our capabilities in hospital supply chain consulting include applied industrial engineering, lean methodologies, systems thinking, and operations research to enable improved patient care and staff satisfaction. We are proud to have worked with over 100 hospitals, including 18 of the top 22 in the US, utilizing diverse design strategies, post-construction implementation, and change management.Join Podchaser to...

- Rate podcasts and episodes

- Follow podcasts and creators

- Create podcast and episode lists

- & much more

Episode Tags

Claim and edit this page to your liking.

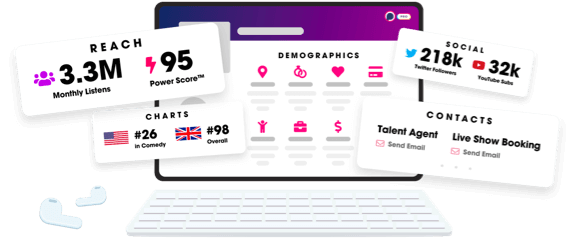

Unlock more with Podchaser Pro

- Audience Insights

- Contact Information

- Demographics

- Charts

- Sponsor History

- and More!

- Account

- Register

- Log In

- Find Friends

- Resources

- Help Center

- Blog

- API

Podchaser is the ultimate destination for podcast data, search, and discovery. Learn More

- © 2024 Podchaser, Inc.

- Privacy Policy

- Terms of Service

- Contact Us